High-water repellency high-photopermeability biodegradable cotton agricultural thin film

A biodegradable and water-repellent technology, applied in the direction of special paper, reinforcing agent addition, paper, etc., can solve the problems of fragility, poor wind and rain resistance of paper mulch film, and environmental hazards, so as to improve dry strength and wet strength, production method Simple, less white pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

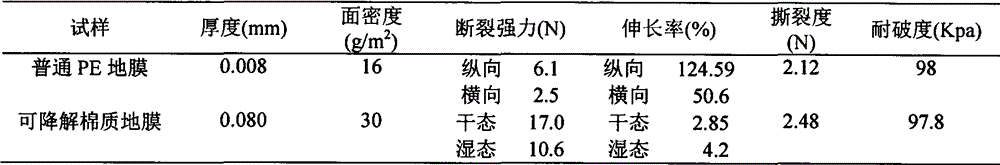

Image

Examples

Embodiment

[0013] Embodiment: The pulping method integrating steaming and bleaching is adopted, and the cotton pulp is cooked with alkali. Sodium hydroxide is the main component of cooking liquid, hydrogen peroxide is bleaching agent, wherein the amount of alkali used is 5%, the amount of hydrogen peroxide is 6%, the amount of sodium laurylsulfonate is 1.5%, the amount of dicyandiamide is 0.2%, and the amount of ethylenediamine The consumption of tetraacetic acid (EDTA) is 0.05%, the consumption of anthraquinone is 0.03%, etc., and the liquid ratio is 1:5. In order to increase the dry and wet strength of the cotton film, some auxiliary agents need to be added during the preparation of the cotton film. For example, the wet strength agent is polyamide epichlorohydrin resin (PAE), and the dosage is 1.0% of the absolute dry pulp mass fraction; The plasticizer is glycidyl ether epoxy resin, and the dosage is 0.7% of the mass fraction of the dry pulp; the dosage of cellulase, the degradant, is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com