Four-column framework diamond string-bead rope gang saw

A diamond beaded, four-column technology, applied in the field of machinery, can solve the problems of frequent saw blade replacement, long adjustment time, and large environmental pollution, and achieve good sawing quality, less replacement times, and smooth sawing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

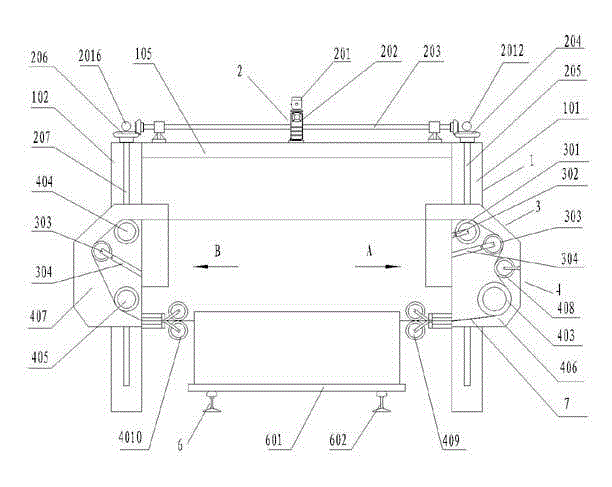

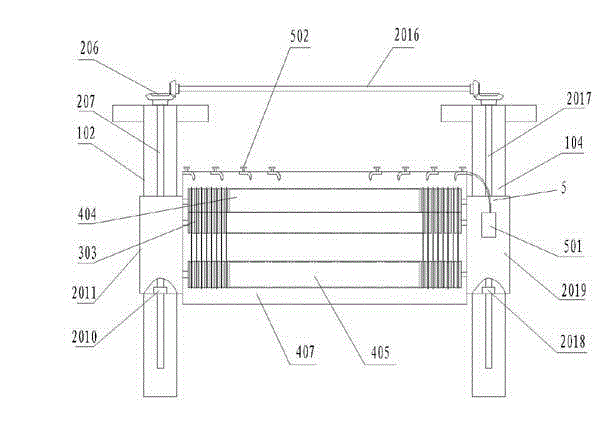

[0030] exist figure 1 , figure 2 , image 3 Among them, a four-column frame diamond beaded wire gang saw, which includes a frame 1, a lifting mechanism 2, a tensioning mechanism 3, a gang saw running mechanism 4, a water supply cooling mechanism 5, a block car 6 and several diamond beaded ropes 7.

[0031] Such as figure 1 , figure 2 , image 3 As shown, the frame 1 is composed of the first column 101, the second column 102, the third column 103, the fourth column 104 and a beam 105 fixedly connected between the top of the first column 101 and the second column 102, a fixed connection A portal frame formed by a beam (not shown in the figure) between the tops of the third column 103 and the fourth column 104 .

[0032] It should be noted that, in order to enhance the connection strength between the four uprights, crossbeams can also be fixedly connected between the tops of the first upright 101 and the third upright 103, and between the tops of the second upright 102 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com