High-stability sliding table saw

A high-stability sliding table saw technology, which is applied in the direction of circular saws, sawing equipment, wood processing equipment, etc., can solve the vibration and displacement increase of the mobile table, reduce the processing accuracy of the plate, and increase the gap between the sliding groove and the guide rail, etc. problem, to achieve the effect of improving service life and stability, improving sawing efficiency, and good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

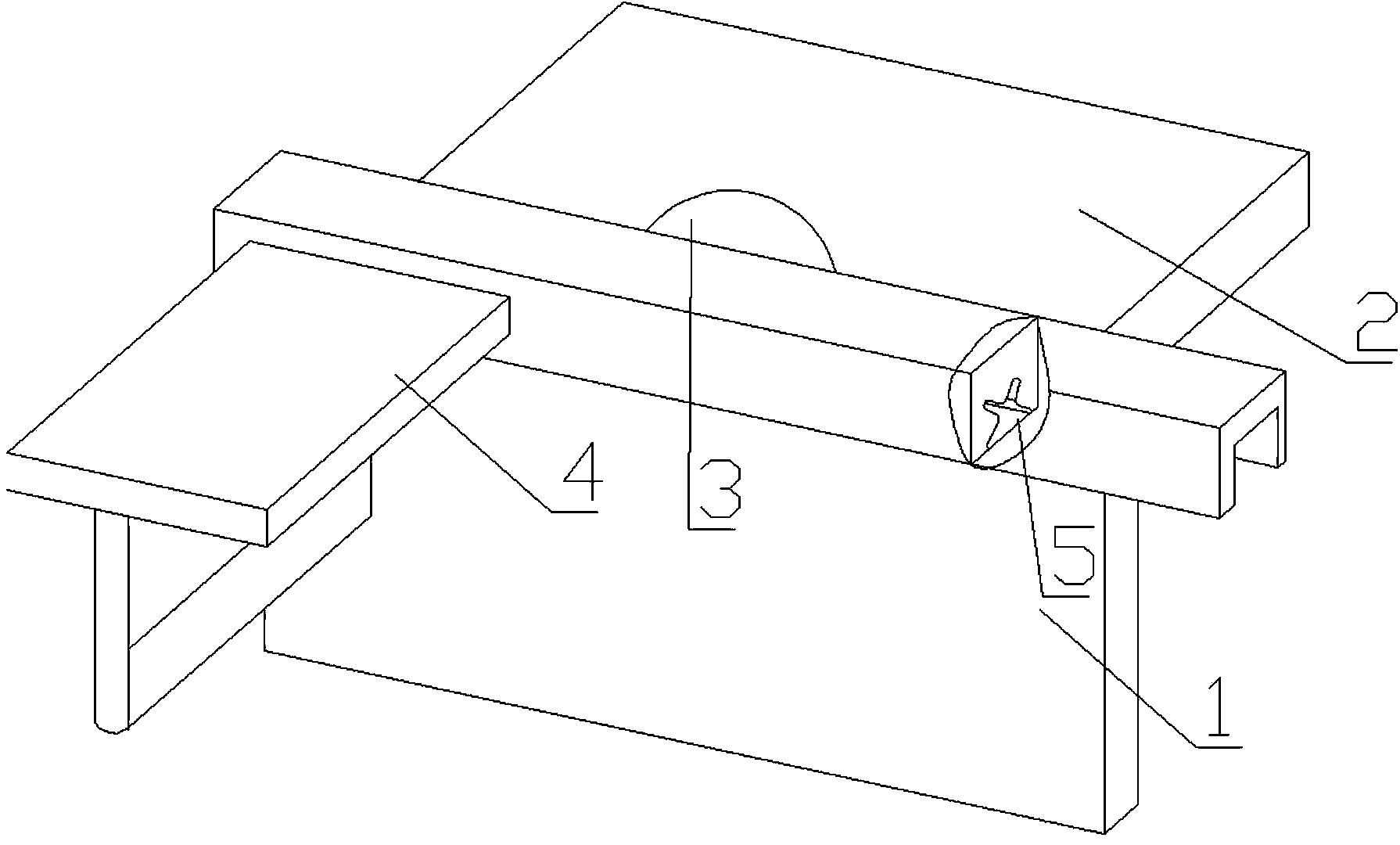

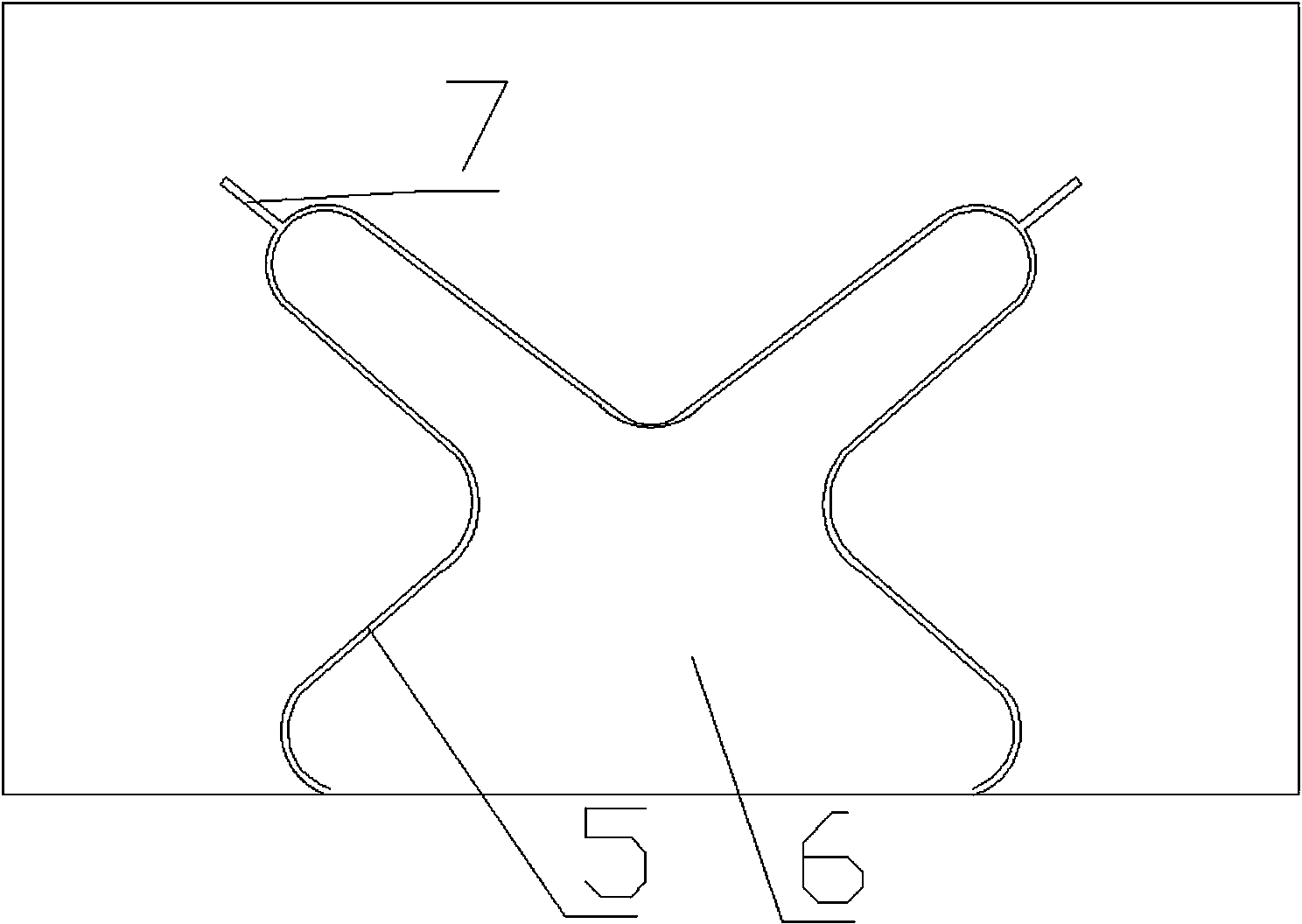

[0011] Embodiments of the invention. High-stability sliding table saws, such as Figures 1 to 3 As shown, the frame 1 for making a sliding table saw is installed on the frame 1 with a working table 2 and a movable table 4, and a saw blade 3 is installed on the working table 2, and the saw blade 3 is connected to a motor through a transmission mechanism. The mobile platform 4 slides on the frame 1 through the cooperation of the sliding groove 5 and the guide rail 6, wherein the cross section of the sliding groove 5 and the guide rail 6 is X-shaped or I-shaped. In order to improve the lubricating effect, an oil groove 7 is opened on the sliding groove 5, and the oil groove 7 is set at the end position of the sliding groove 5, so that the lubricating effect is better.

[0012] After testing, the cross-section of the sliding groove 5 and the guide rail 6 is preferably X-shaped. The X-shaped structure not only can cooperate with the two protruding end faces, but also can play a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com