Steel pipe fixture for pipe saw mills

A technology of clamping device and sawing steel pipes, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of long downward stroke of the saw blade, large vibration and impact, uneven load, etc., and improve the saw blade Longer life, less impact on the saw blade, and less chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

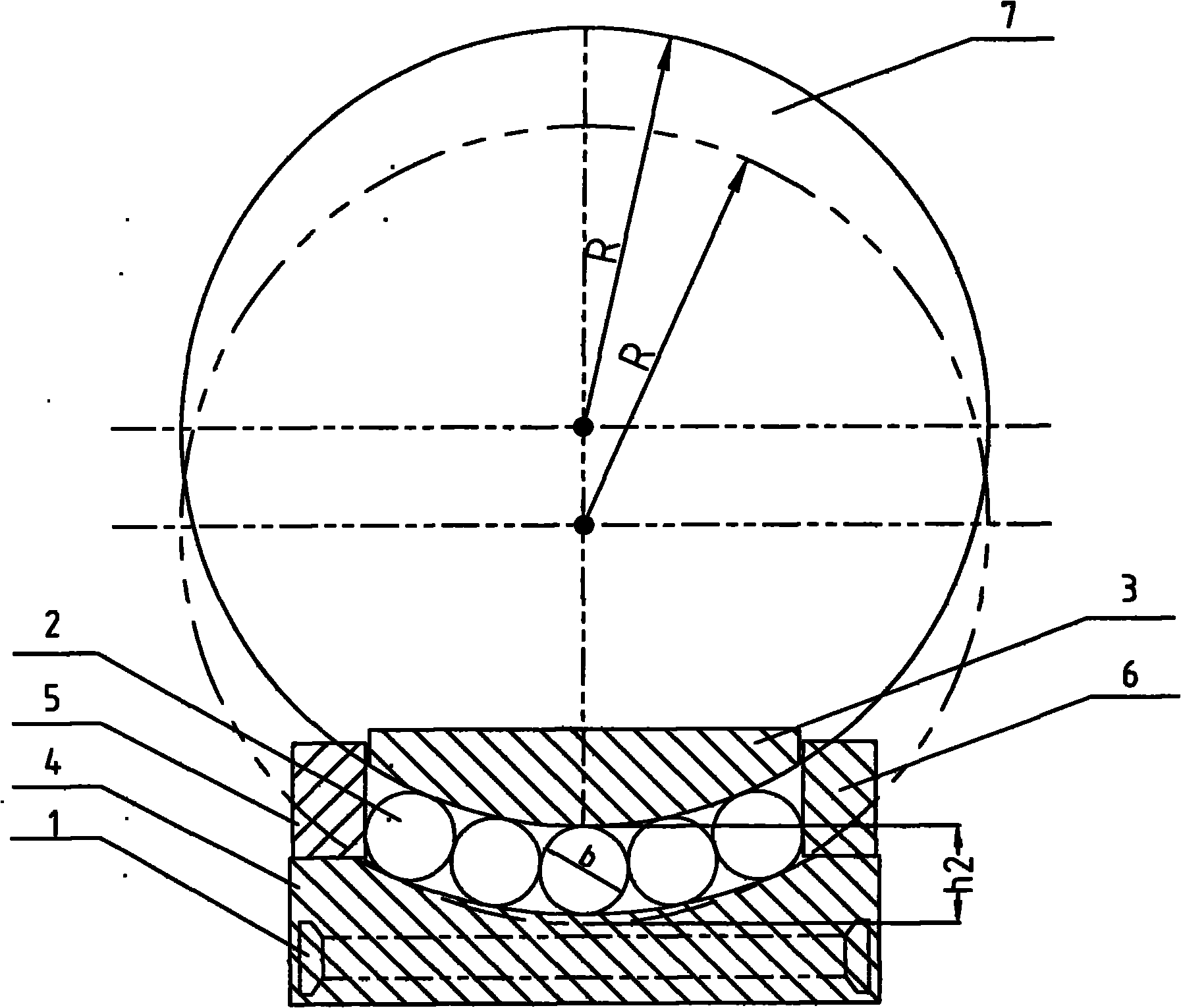

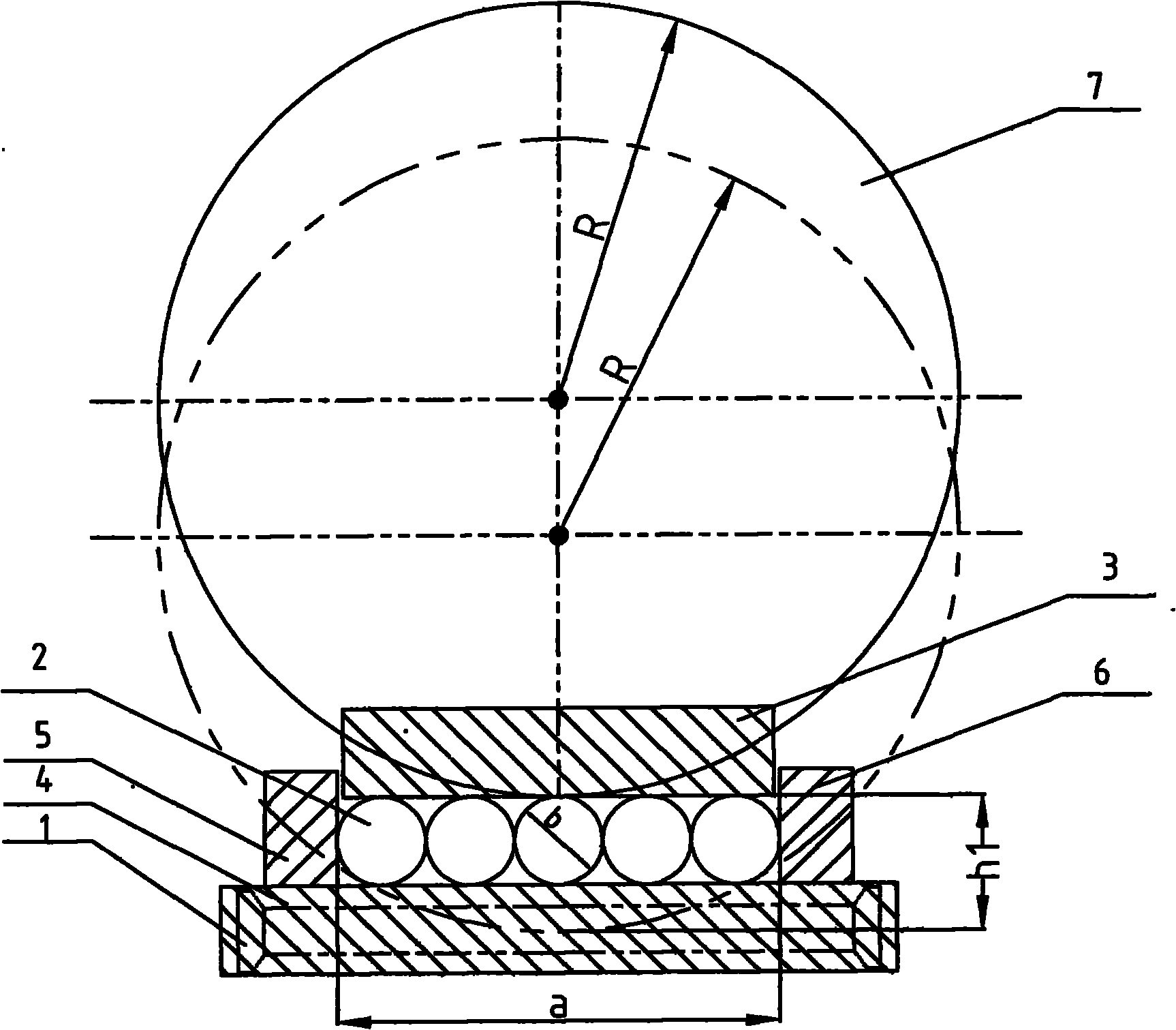

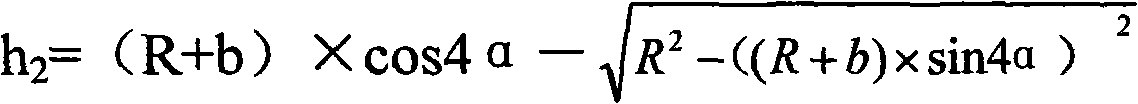

[0013] Example 1: see figure 1 , install a pipe gang saw, select the saw blade 7 radius R is Φ900mm, the diameter b of the cutting steel pipe 2 is Φ200mm, the width of the conveying roller table 1 is 1000mm, 5 steel pipes 2 form a row of simultaneous sawing, and the clamping device consists of The upper splint 3, the lower splint 4, the left splint 5, and the right splint 6 are composed. The surfaces of the upper splint 3 and the lower splint 4 in contact with the steel pipe 2 are arc-shaped, and the two arcs have a common center of circle, and the two concentric arcs The radius difference is the diameter of the clamped steel pipe 4 .

[0014] The process flow is: the conveying roller table 1 conveys the steel pipe 2, and the head of the steel pipe 2 stops when it encounters the positioning baffle; The steel pipe 2 is horizontally centered and clamped; finally, the upper splint 3 descends, and the lower splint 4 clamps the steel pipe 2 on the vertical plane; at this time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com