A small hole thread forming grinding wheel for grinding hard and brittle materials

A technology for forming grinding wheels and hard and brittle materials, which is applied in thread cutting tools, metal processing equipment, thread cutting devices, etc., can solve problems such as unavailable applications and large principle errors, and achieve good processing quality, long life of grinding wheels, and high-efficiency precision machining Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

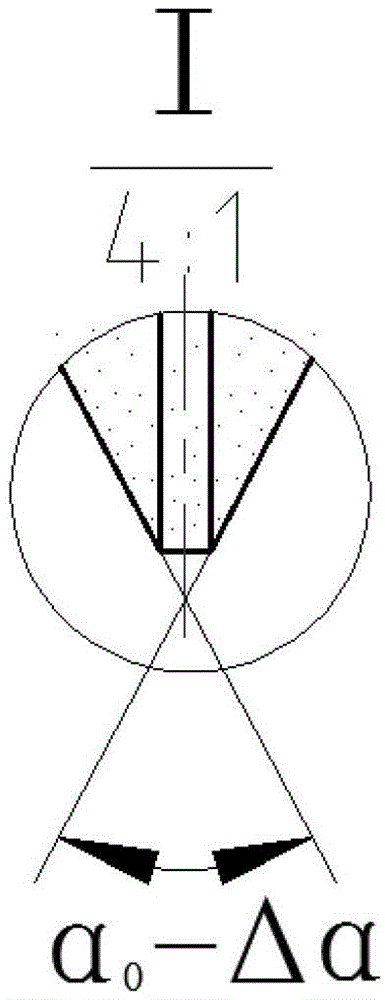

[0022] Such as Figure 1 ~ Figure 2 As shown, a threaded grinding wheel for forming and grinding ordinary standard thread M2 small holes includes a disc-shaped forming grinding wheel 1 and a grinding wheel rod 2 . The diameter of grinding wheel rod 2 is less than the bottom hole diameter, gets φ 1mm, and the effective length of grinding wheel rod 2 gets 4mm, and the diameter of knife handle 3 is φ 3mm. The disc-shaped forming grinding wheel 1 is prepared by electroplating diamond abrasives, the disc-shaped forming grinding wheel 1, the grinding wheel rod 2 and the handle 3 adopt an integral structure, and the material is hard alloy.

[0023] 1) The diameter of the disc forming grinding wheel 1 is φ1.5mm, which is slightly smaller than the diameter of the bottom hole of the M2 thread φ1.6mm.

[0024] 2) if figure 2 As shown, the included angle of the axial section of the disc-shaped forming grinding wheel 1 is 56°, that is, the amount of modification α=4°.

[0025] 3) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com