Method for preparing nano-silver hydrosol by using plant extract

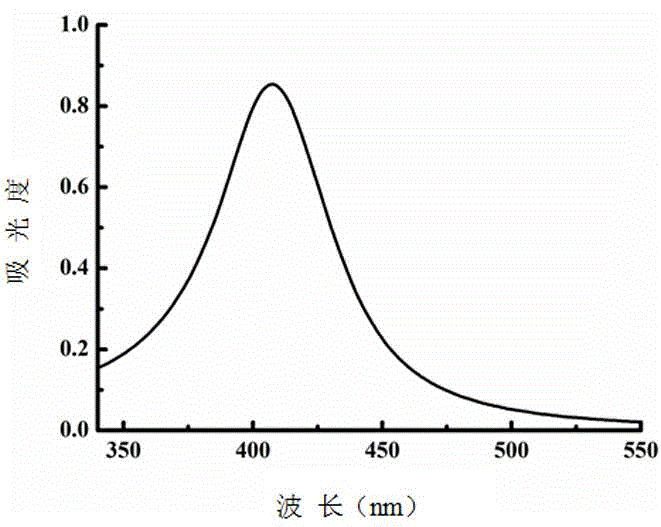

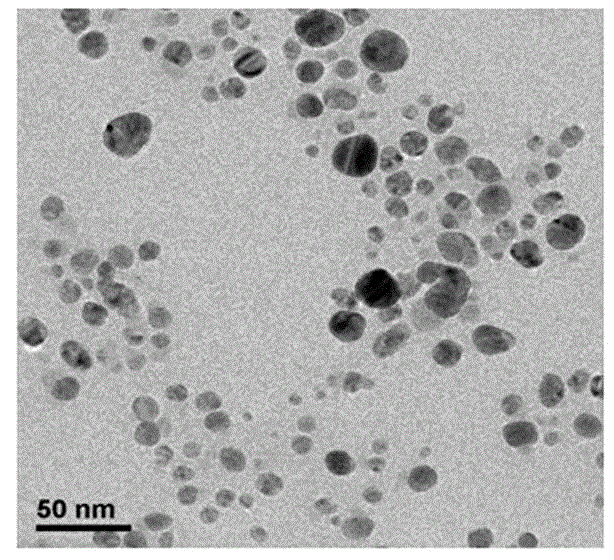

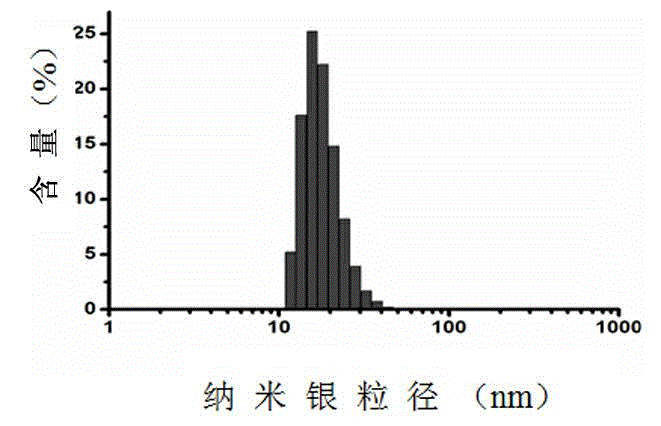

A plant extract and hydrosol technology, applied in the field of nanomaterials, can solve the problems of potential harm to the environment and organisms, wide product particle size distribution, narrow particle size distribution, etc., and achieve high antibacterial efficiency, uniform distribution, and small particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Disperse 0.1g of cornstarch in 10ml of deionized water, stir at 80°C until gelatinized to obtain a starch solution, add it to 20ml of silver ammonia solution with a concentration of 1wt%, and mix evenly. The silver ammonia solution is silver nitrate and ammonia water The complex formed after mixing is obtained into a starch-silver ion composite solution, and the composite solution is frozen at -20°C, and crushed after it freezes to obtain about 30g of ice powder with a particle size of 1-3mm .

[0027] The aloe leaves are washed with deionized water and peeled to obtain aloe vera, then cut into pieces, pulverized, filtered, separated and purified to obtain an aloe leaf extract, dispersed in deionized water, and prepared with 300ml of aloe with a concentration of 10 wt%. Aqueous solution of leaf extract, NaOH solution to adjust its pH to 11 to obtain alkaline aloe leaf extract; add the above-mentioned ice powder to alkaline aloe leaf extract, stir at 40°C for 300min, and...

Embodiment 2

[0029] Disperse 0.05g of tapioca starch in 5ml of deionized water, stir at 90°C until gelatinized to obtain a starch solution, add it to 20ml of silver ammonia solution with a concentration of 0.5wt%, and mix evenly. The silver ammonia solution is silver sulfate and A complex formed after mixing ammonia water to obtain a starch-silver ion composite solution. The composite solution is frozen at -10°C and crushed after freezing to obtain ice powder with a particle size of about 1-3mm. 25g.

[0030] Wash and peel the cactus with deionized water to obtain inner denim, then cut into pieces, crush, filter, separate, and purify to obtain cactus extract, disperse in deionized water, and prepare 175ml of cactus leaf extract with a concentration of 40 wt%. Liquid aqueous solution, NaOH solution to adjust its pH to 10.7 to obtain an alkaline cactus leaf extract; add the prepared ice powder to the alkaline cactus leaf extract, and stir at 30°C for 300min to obtain a nanosilver hydrosol. ...

Embodiment 3

[0035] Disperse 0.05g of wheat starch in 10ml of deionized water, stir at 90°C until gelatinized to obtain a starch solution, add it to 20ml of silver ammonia solution with a concentration of 0.2wt% and mix evenly, the silver ammonia solution is silver sulfate and A complex formed after mixing ammonia water to obtain a starch-silver ion composite solution. The composite solution is frozen at -10°C and crushed after freezing to obtain ice powder with a particle size of about 1-3mm. 30g.

[0036] Prepare aloe vera leaf extract and cactus extract according to embodiment 1 and 2 technical scheme. 200ml concentration is 20 wt % aloe vera leaf extract aqueous solution and 250ml concentration is 30 wt % cactus leaf extract aqueous solution mixes, and NaOH solution adjusts its pH to 10.7 to obtain alkaline plant leaf extract; Add above-mentioned ice powder to alkali In the leaf extract of sexual plants, stir at 50°C for 120 minutes to obtain nano-silver hydrosol with a particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com