Titanium aluminum alloy blade blank continuous cold crucible directional solidification casting device

A titanium-aluminum alloy, directional solidification technology, which is applied in the field of continuous cold crucible directional solidification casting device, can solve the problems such as difficult to form directional solidification structure, and cannot form titanium-aluminum alloy blade castings, so as to avoid mold shell pollution and reduce adverse effects , the effect of shortening the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

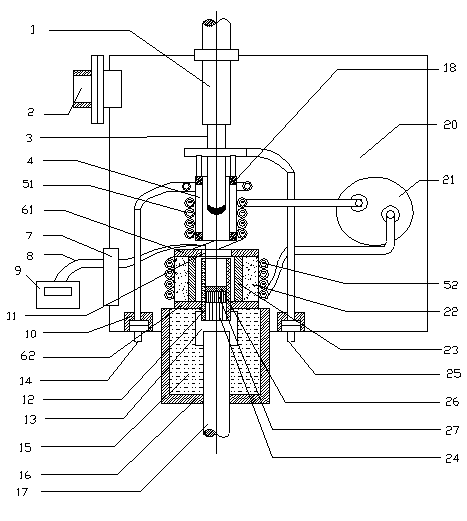

[0048] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] The specific structure of the device of the present invention is as follows figure 1 As shown, it includes the masterbatch fixing and supply system of the material to be processed, the fixing system of the initial base material, the vacuuming and argon gas filling system, the cooling system for supplying circulating cooling water, and the power supply supplying the energy system required for the solidification process , The feeding and sending motion system for supplying the masterbatch and the final solidified alloy billet, and the solidification cooling system for the solidified billet in the crystallizer, etc.

[0050] Specifically described as:

[0051] This embodiment includes a closed furnace body, a feeding rod, a titanium-aluminum alloy parent bar, a water-cooled copper crucible, an upper induction coil, a crystallizer, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com