Preparation method of light emitting diode with photonic crystals with gradually-changed radius

A technology of light-emitting diodes and photonic crystals, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as low external quantum efficiency of light-emitting diodes, low light extraction efficiency, and restrictions on the development of light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

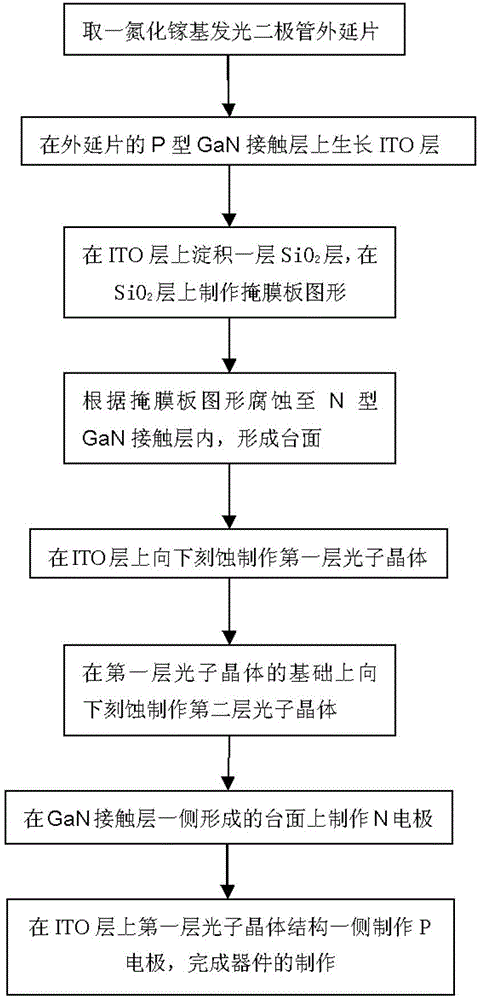

[0018] see figure 1 and refer to Figure 2-Figure 5 Shown, the present invention provides a kind of preparation method of photonic crystal light-emitting diode of gradual change radius, comprises the following steps (referring to figure 1 ):

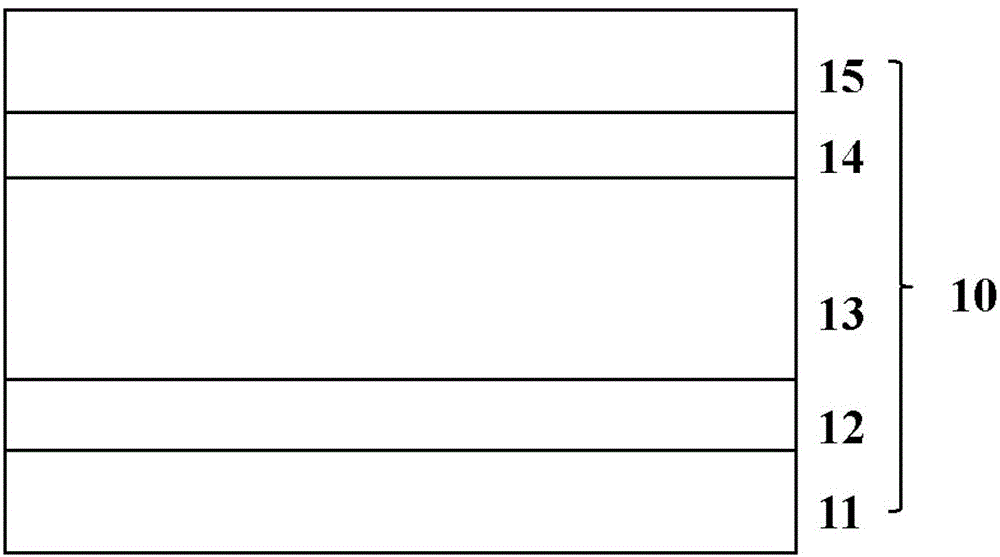

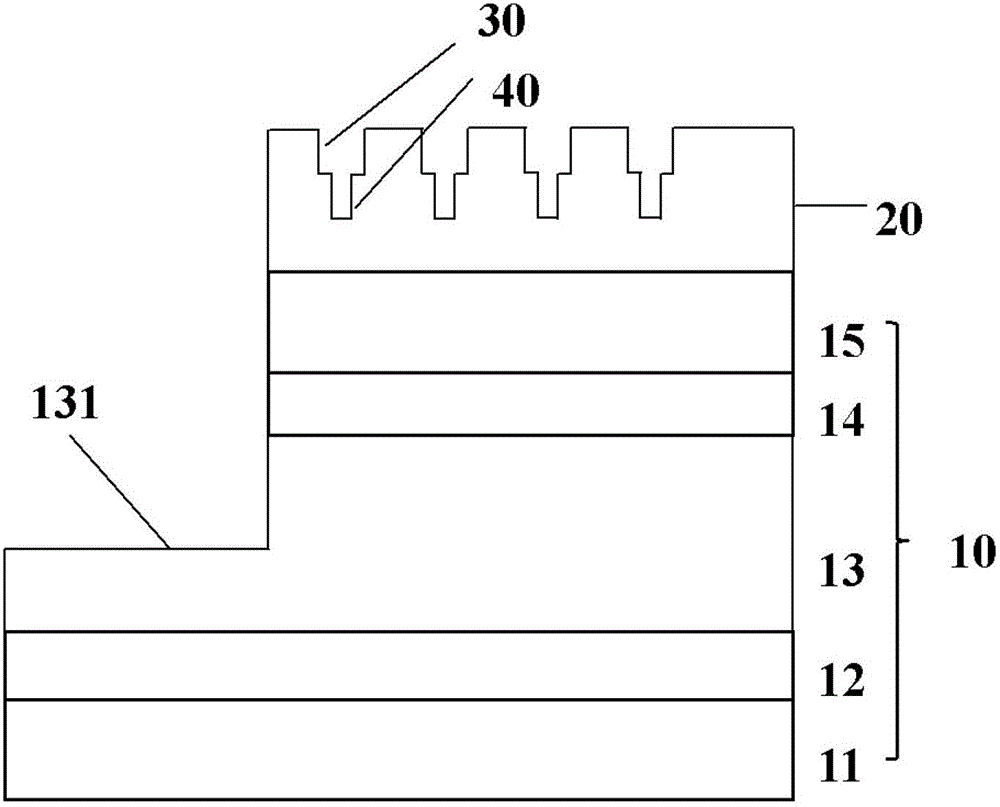

[0019] Step 1: Take a gallium nitride-based light-emitting diode epitaxial wafer 10, the epitaxial wafer 10 includes a GaN buffer layer 12 grown sequentially on a substrate 11 by metalorganic chemical vapor deposition or suspended epitaxial wafer technology, an N-type GaN contact Layer 13, active layer 14 and P-type GaN contact layer 15, the material of substrate substrate 11 in this epitaxial wafer 10 is sapphire, silicon, ZnO or SiC (see figure 2 );

[0020] Step 2: On the P-type GaN contact layer 15 of the epitaxial wafer 10, grow an ITO layer 20 by magnetron sputtering, evaporation, chemical vapor deposition or thermal spraying. The ITO layer has been alloyed to have low resistivity and high light transmission Efficiency charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com