Packaging device of compact single-phase integrated drive circuit and single-phase integrated drive circuit

A technology that integrates driving and packaging devices, applied in circuits, excitation or armature current control, electrical components, etc., can solve the problems of reduced lead center distance, insufficient lead center distance, mutual damage, etc., and achieve volume reduction and reduction. Overall cost, solving the effect of reducing pin center distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

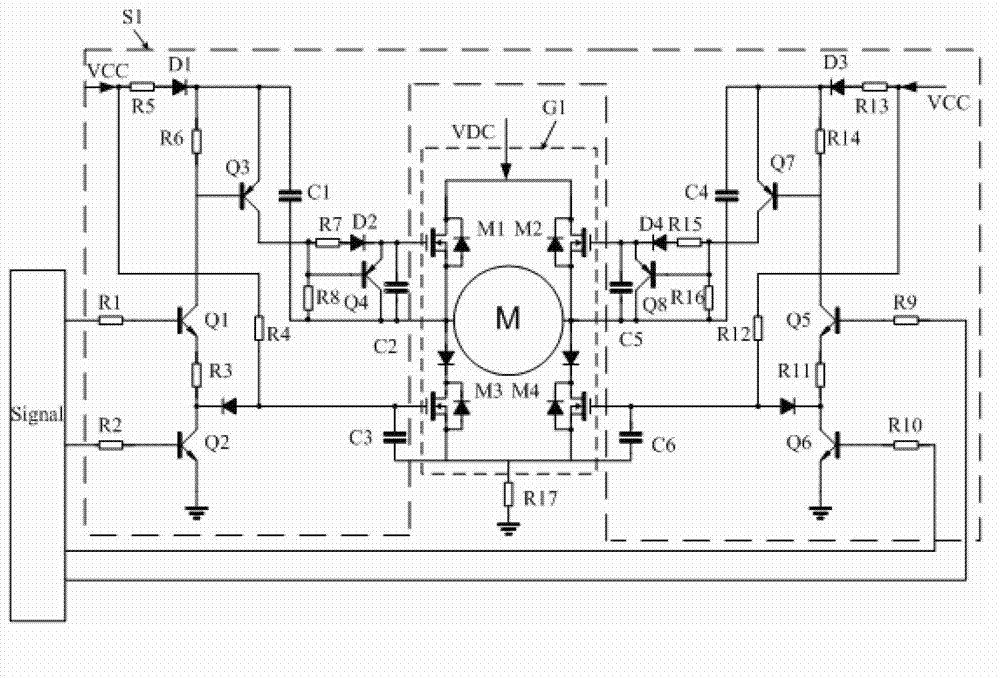

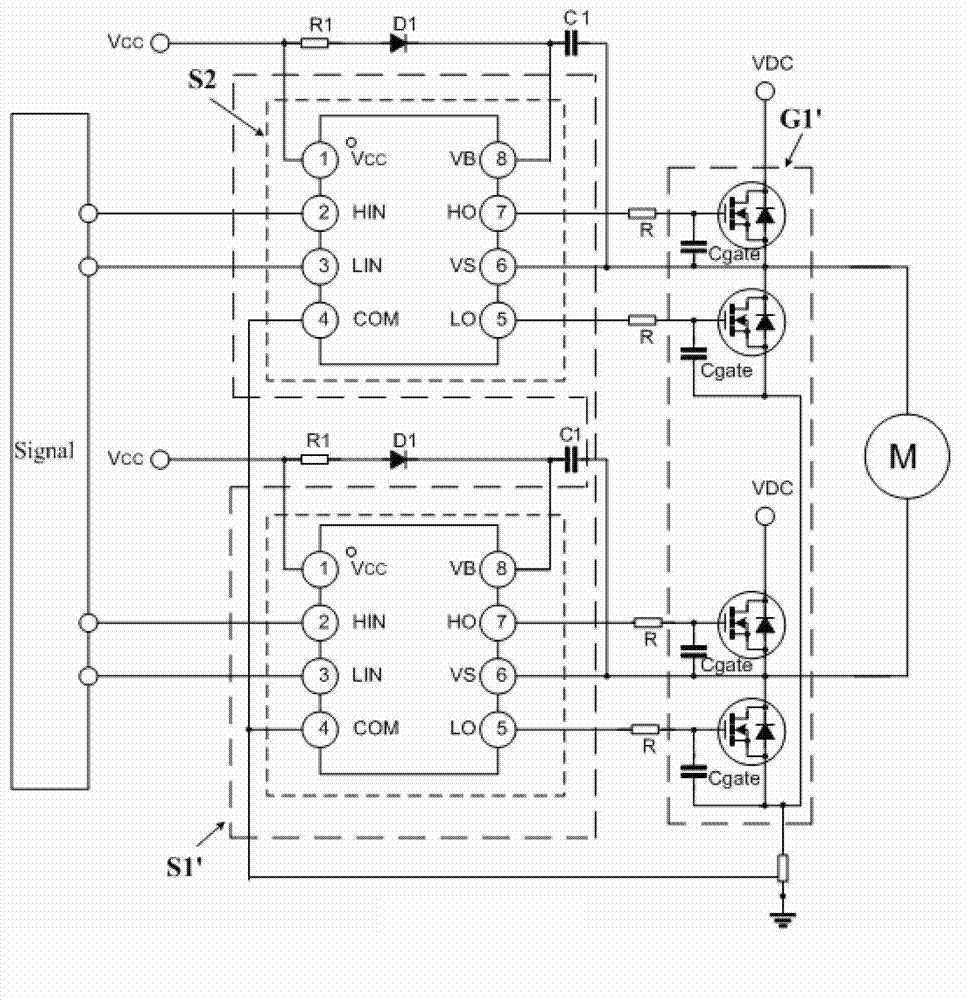

[0062] The present invention proposes a packaging device for a compact single-phase integrated drive circuit, such as Figure 4 As shown, the packaging device 100 of the compact single-phase integrated driving circuit includes a lead frame 102 on which a plurality of first chip base islands are formed. The plurality of first chip base islands include a first gate drive chip base island 104, a second gate drive chip base island 106, a first upper arm chip base island 108, a first lower arm chip base island 110, a second upper arm chip base island 110, and a second upper arm chip base island 108. chip base island 112 and the second lower arm chip base island 114 . Wherein, the first gate driver chip base island 104 and the second gate driver chip base island 106 are formed on an inner side of the lead frame, and the first upper arm chip base island 108 and the first lower arm chip base island 110. The second upper arm chip base island 112 and the second lower arm chip base isla...

Embodiment 2

[0093] On the basis of embodiment one, see Figure 9 , and combined with Figure 10 with Figure 11 , the packaging device of the compact single-phase integrated drive circuit further includes: a first bootstrap diode pad 69 and a second bootstrap diode pad 59, the first bootstrap diode pad 69 is formed on the On the first gate driver 104 , the second bootstrap diode pad 59 is formed on the second gate driver 106 .

[0094] The packaging device of the compact single-phase integrated drive circuit further includes a first bootstrap diode chip base island and a second bootstrap diode chip base island, the first bootstrap diode chip base island is formed on the lead frame, And close to the first gate driver chip base island, the second bootstrap diode chip base island is formed on the lead frame and close to the second gate drive chip base island.

[0095] The packaging device of the compact single-phase integrated drive circuit also includes a first bootstrap diode chip 80 an...

Embodiment 3

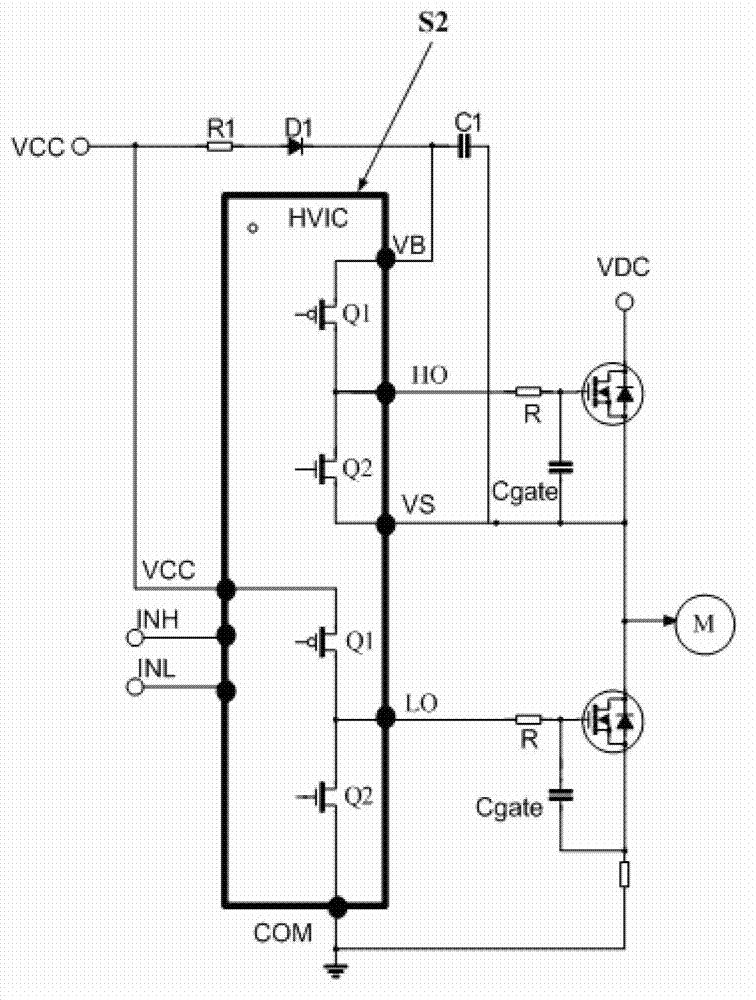

[0101] On the basis of Embodiment 1 or Embodiment 2, the packaging device 100 of the compact single-phase integrated drive circuit further includes: a plurality of second chip base islands formed on the lead frame 102, and mounted on each Each of the switch units on the second chip base island is formed by connecting an upper arm switch unit and a lower arm switch unit in end-to-end series.

[0102] Preferably, each of the upper arm switch units includes an on resistor RG_ON, and each of the lower arm switch units includes an off resistor RG_OFF.

[0103] The start end, the middle end and the end end of one of the end-to-end series switch units respectively receive the first upper arm bias voltage VB1, the first upper arm drive signal HO1 and the first upper arm bias voltage ground VS1; the other end-to-end The start end, the middle end and the end end of the switch units connected in series respectively receive the first gate drive bias voltage VCC1, the first lower arm drive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com