Moisture-sensitive sensor based on titanium-containing organic framework material and preparation method thereof

A metal-organic framework and moisture-sensitive sensor technology, applied in the direction of material impedance, etc., to achieve high specific surface area, good detection performance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

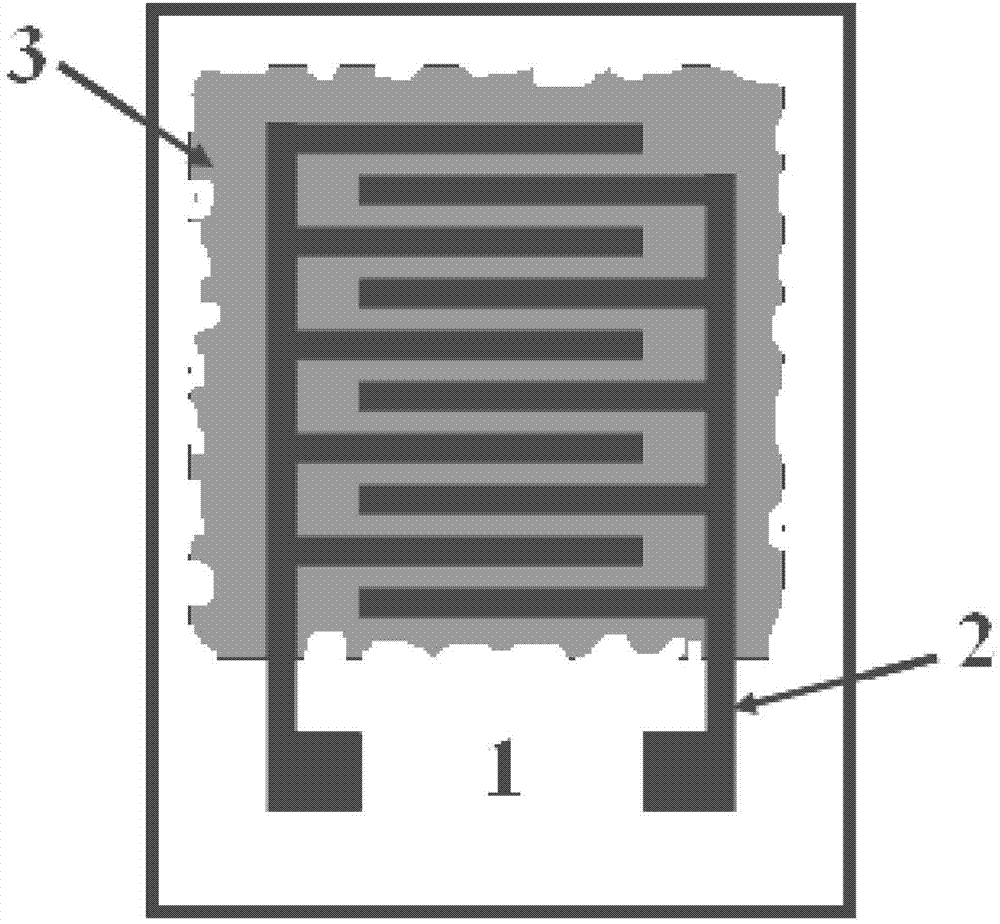

[0030] First, wipe the substrate with acetone and ethanol cotton balls until it is clean, then place the substrate in acetone, ethanol and deionized water in sequence, ultrasonically clean it for 5 minutes, and finally dry it at 100°C for later use;

[0031] Au metal interdigitated electrodes were prepared by screen printing technology. According to the ratio of ink: Au powder: diluent mass ratio of 1:1.5:3, the Au powder was stirred to make a paste; the paste was injected into the On the screen plate of the electrode pattern, the paste is scraped at a certain inclination angle (30°) and pressure (5 N), the electrode is printed and dried, and then cured by ultraviolet light, thereby completing the preparation of the metal interdigitated electrode.

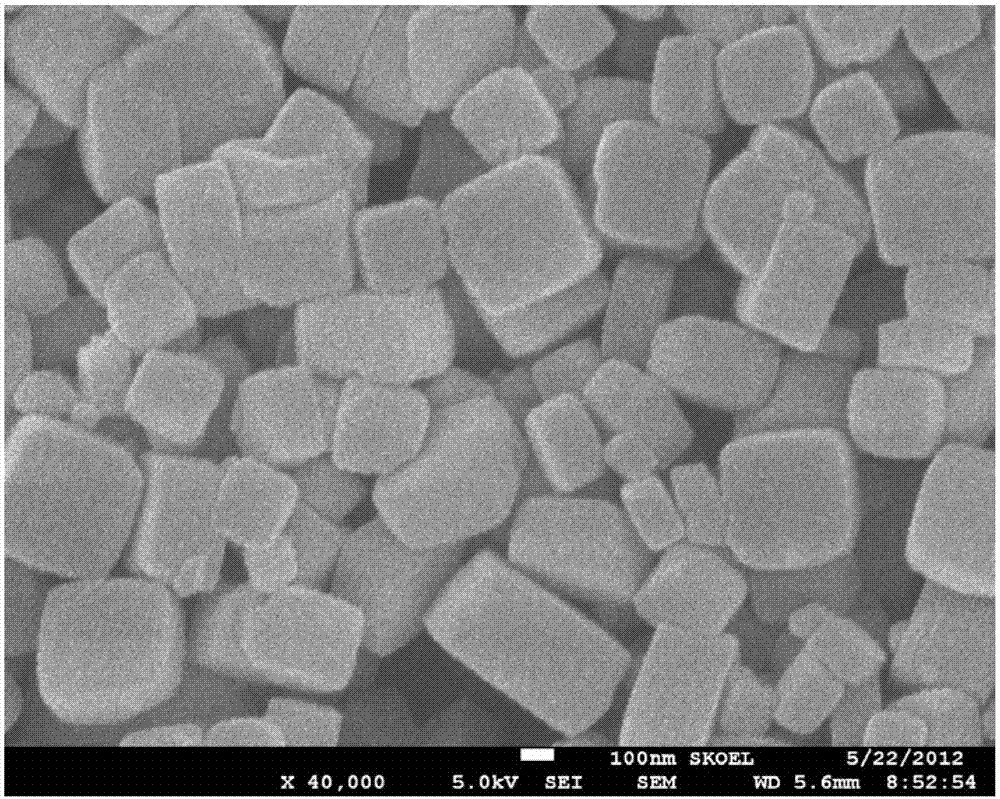

[0032] Prepare MIL-125(Ti) by hydrothermal method: at room temperature, dissolve 0.5g terephthalic acid, 0.25mL titanium tetraisopropoxide in a mixed solution of 9mL N, N-dimethylformamide and 1mL ethanol , stirred evenly, then tra...

Embodiment 2

[0036] First, wipe the substrate with acetone and ethanol cotton balls until it is clean, then place the substrate in acetone, ethanol and deionized water in sequence, ultrasonically clean it for 5 minutes, and finally dry it at 100°C for later use;

[0037] The preparation process of the Au metal interdigitated electrode is the same as that in Example 1.

[0038] Preparation of MIL-125(Ti) by hydrothermal method: the experimental process is the same as in Example 1.

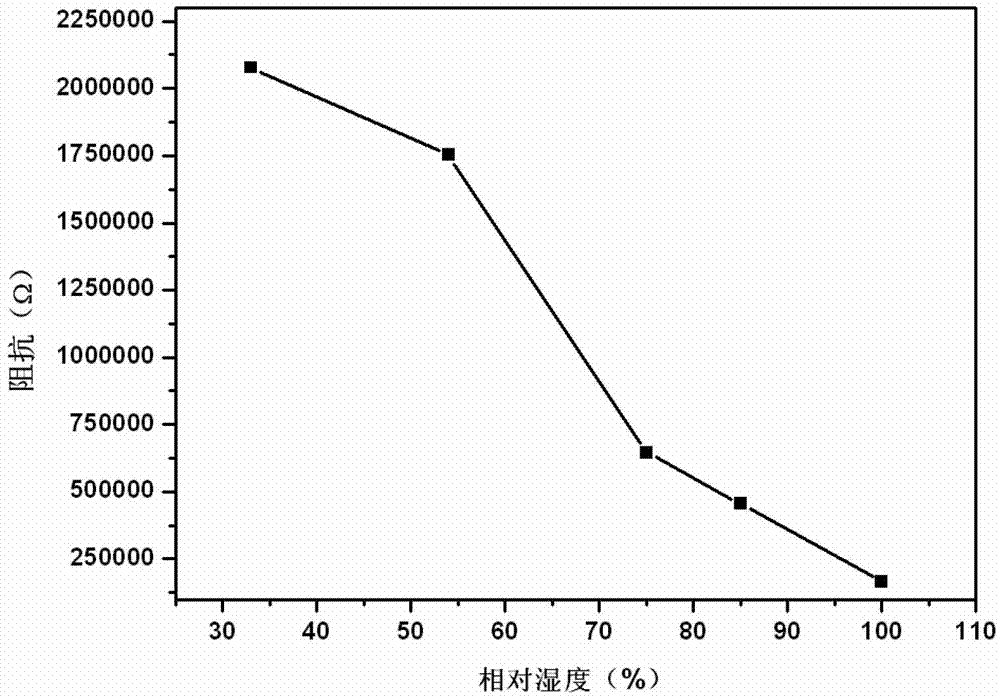

[0039] Put the prepared sensitive material into a mortar and grind thoroughly for 30 minutes. Then drop deionized water into the mortar (the mass ratio of sample to water is 5:1), and continue to grind for 30 minutes to obtain a viscous slurry; dip a small amount of sensitive film slurry with a medicine spoon, and apply it on On the substrate, the number of times of coating is 2 times, and then dried at 60°C to obtain an element with a sensitive film thickness of 3 μm. Place the above-prepared element in a hum...

Embodiment 3

[0042] First, wipe the substrate with acetone and ethanol cotton balls until it is clean, then place the substrate in acetone, ethanol and deionized water in sequence, ultrasonically clean it for 5 minutes, and finally dry it at 100°C for later use;

[0043] The preparation process of the Au metal interdigitated electrode is the same as that in Example 1.

[0044] Preparation of MIL-125(Ti) by hydrothermal method: the experimental process is the same as in Example 1.

[0045] Put the prepared sensitive material into a mortar and grind thoroughly for 30 minutes. Then drop deionized water into the mortar (the mass ratio of sample to water is 5:1), and continue to grind for 30 minutes to obtain a viscous slurry; dip a small amount of sensitive film slurry with a medicine spoon, and apply it on On the substrate, the number of coatings is 3 times, and then dried at 60° C. to obtain an element with a sensitive film thickness of 4 μm. Place the above-prepared element in a humidity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com