Metal glass composite material with high-oxygen content and preparation method thereof

A composite material and metal glass technology, applied in the field of metal matrix composite materials, can solve problems such as reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

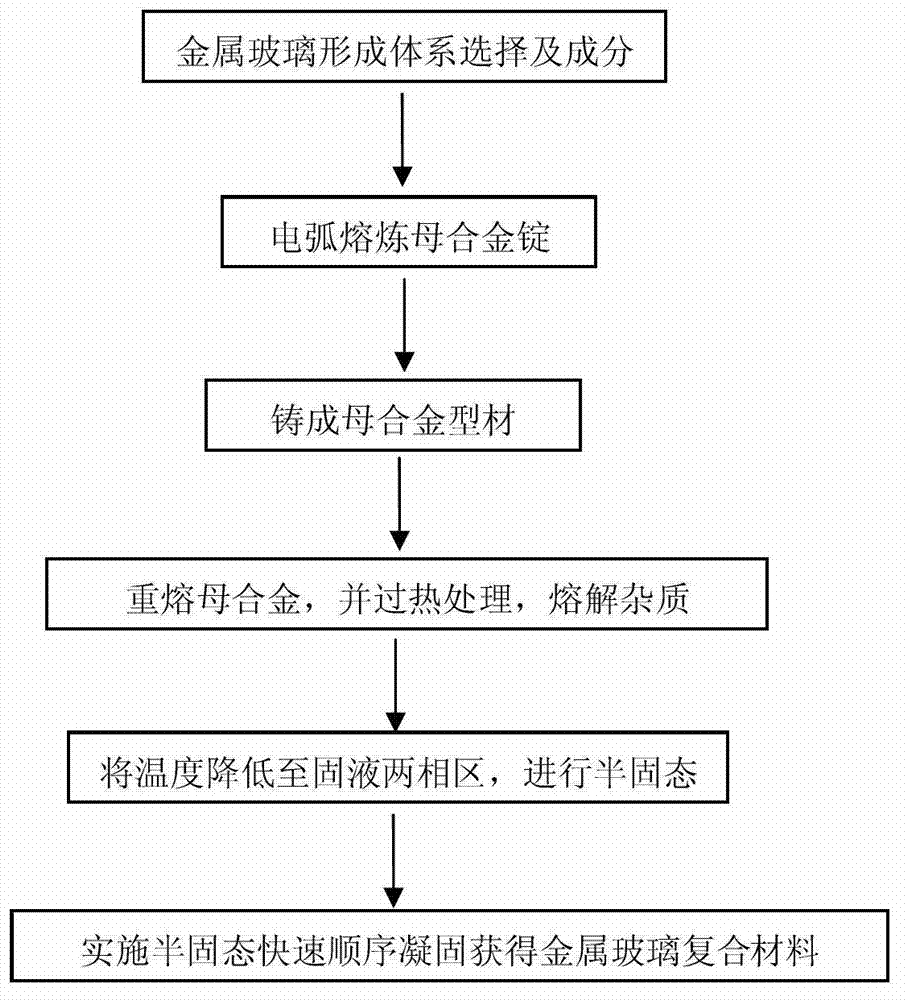

[0022] A kind of metal glass composite material with high oxygen content of the present invention, its preparation method comprises the following steps:

[0023] The first step: select the alloy elements with a purity greater than 99.5%, and make a ratio according to the predetermined composition, and first mix Zr and ZrO in a pure argon atmosphere electric arc furnace 2 、TiO 2 One or several of CuO or BeO are mixed and smelted evenly, or low-purity high-oxygen sponge zirconium and sponge titanium raw materials are used for melting in low vacuum, and then other elements are added to melt together to make the alloy composition homogeneous , Suction casting into master alloy profiles.

[0024] Step 2: Put the master alloy profile into the crucible, heat it in a resistance furnace until it is completely melted, and perform overheating treatment to melt the impurity phase.

[0025] Step 3: Adjust the power of the resistance furnace, lower the temperature to the solid-liquid two-...

Embodiment 1

[0040] (1) Selection of raw materials

[0041] The purity of each metal component that the present invention prepares master alloy ingot for selection is as table 1, and alloy composition is Zr 54 Ti 13 Nb 5 Cu 5 Ni 4 be 9 o 10 (atomic percent).

[0042] Table 1 The purity (%) of metal components selected for the preparation of master alloy ingots

[0043] alloy element Zr Ti Nb Cu Ni be ZrO 2 purity / % 99.5 99.5 99.9 99.9 99.9 99..5 99.9

[0044] (2) Preparation of master alloy ingot

[0045] Under the conditions of Ti inhalation and high-purity argon protection, master alloy buckle ingots are melted in a non-consumable arc melting furnace. The specific procedures are as follows:

[0046]a. After mechanically grinding the surface of the metal raw material to remove the oxide skin on the surface, prepare the material according to the designed composition ratio; put the prepared material into the water-cooled copper crucible in t...

Embodiment 2

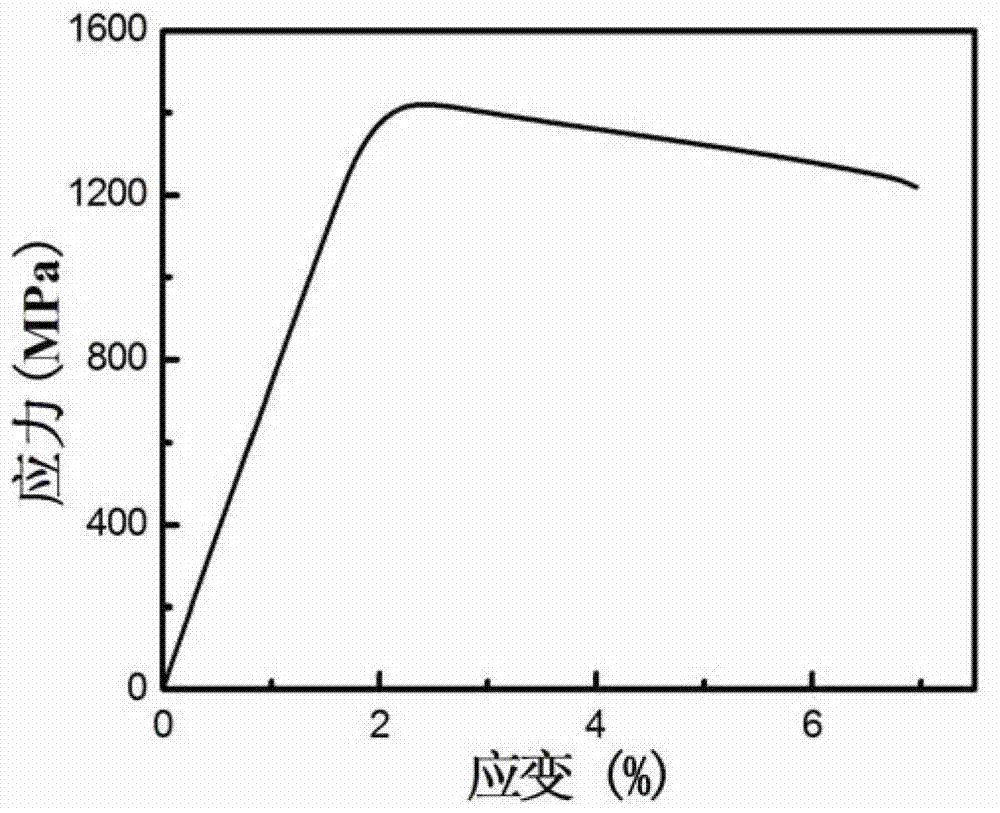

[0058] Adopt the method identical with embodiment 1, alloy composition is Zr 34.7 Ti 34.7 Nb 10.6 Cu 6.0 be 12.0 o 2.0 (atomic percent). The composite sample with a diameter of 30mm prepared at a pulling rate of 2mm / s has a uniform structure, and the tensile strength and plastic strain reach 1300MPa and 9%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com