A kind of nitrogen doped toughened metallic glass composite material and preparation method thereof

A technology of composite material and metallic glass, which is applied in the field of nitrogen-doped toughened metallic glass composite material and its preparation, can solve the problems of reducing strength and achieve the effect of strong-plastic combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

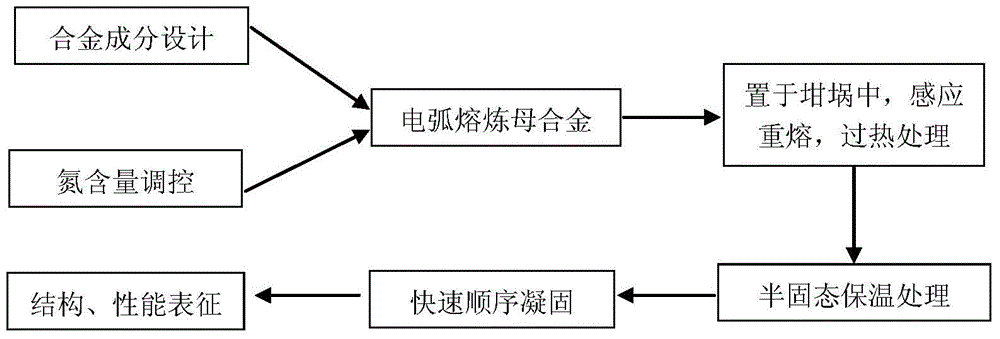

[0026] A method for preparing a nitrogen-doped toughened metallic glass composite material of the present invention comprises the following steps:

[0027] The first step: select the alloy elements with a purity greater than 99.5%, and make the ratio according to the predetermined composition. First, use a non-consumable electric arc furnace to smelt TiN and Ti evenly in a non-consumable electric arc furnace to control the nitrogen content in the alloy, or use The alloy is smelted under a mixed atmosphere of argon and nitrogen to control the nitrogen content in the alloy, and then other elements are added to smelt together to homogenize the alloy composition and suction cast into a master alloy profile.

[0028] Step 2: Put the master alloy profile into the crucible, heat it by induction until it is completely melted, and perform overheating treatment to melt the impurity phase.

[0029] Step 3: Regulate the power of the induction melting furnace, lower the temperature to 850°...

Embodiment 1

[0044] (1) Selection of raw materials

[0045] The purity of each metal component that the present invention prepares master alloy ingot for selection is as table 1, and alloy composition is Ti 56 Zr 16 Nb 8.5 Cu 6 Al 3 be 10 N 0.5 (atomic percent).

[0046] Table 1 prepares the purity (%) of the metal component selected from the master alloy ingot

[0047]

[0048] (2) Preparation of master alloy ingot

[0049] Under the protection of high-purity argon gas, the master alloy button ingot is melted in a non-consumable arc melting furnace. The specific procedure is as follows:

[0050] a. After mechanically grinding the surface of the metal raw material to remove the oxide skin on the surface, prepare the material according to the designed composition ratio; put the prepared material into the water-cooled copper crucible in the melting furnace according to the weight of about 80g per ingot, cover Vacuum the upper furnace cover to 2×10 -3 Pa; Fill the furnace with a ...

Embodiment 2

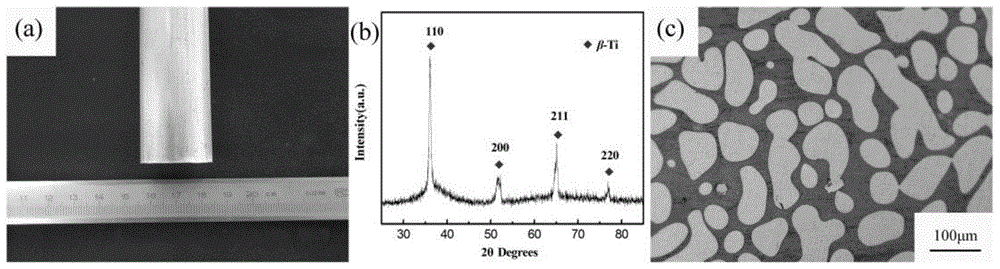

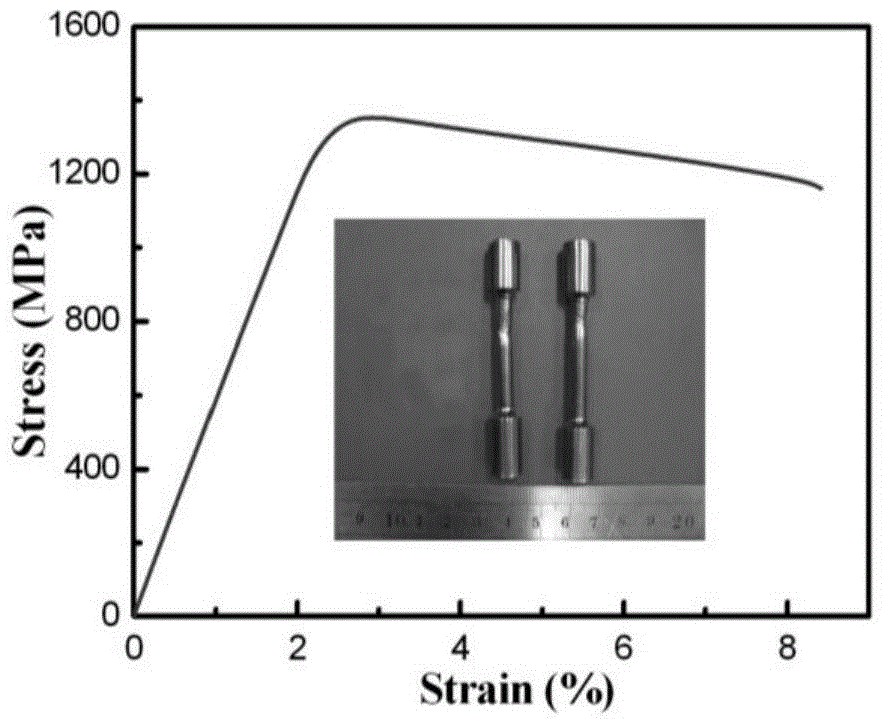

[0061] Adopt the method identical with embodiment 1, alloy composition is Ti 58 Zr 17 Nb 9 Cu 4 Al 3 be 7.5 N 1.5 (atomic percent), kept at 850°C for 40 minutes, and then prepared at a pulling rate of 3mm / s, the composite sample with a diameter of 30mm had a uniform structure, and nearly spherical β-Ti with a size of about 40μm was uniformly distributed on the metallic glass substrate phase, its volume fraction is about 70%. The room temperature tensile strength and plastic strain of the composite reached 1180MPa and 8.5%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com