Waterborne polyurethane primer for coating plastic film and preparation method thereof

A water-based polyurethane and plastic film technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of restricting the development of coating films, operators' physical and environmental hazards, and unsatisfactory use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Add 3.6 kilograms of polycaprolactone diol and 0.3 kilograms of dimethylol propionic acid to the reaction vessel, and feed N 2 protection, stirring and raising the temperature to 70° C., adding 0.24 kg of isophorone diisocyanate and reacting for 1 hour to prepare prepolymer A.

[0029] 2. Dissolve 0.03 kg of diethylenetriamine and 0.3 kg of ammonia water in 22.16 kg of water to form mixed solution B.

[0030] 3. Slowly add the mixed solution B into the prepolymer A, and add 1.2 kg of N-methylpyrrolidone to adjust the viscosity of the emulsion to 12s. At this time, the amount of N-methylpyrrolidone added accounted for 4.5% of the total mass of the prepolymer A and the mixed solution B. At room temperature, increase the rotation speed to 2000 rpm, raise the temperature to 40°C, and keep it for 1 hour.

[0031] 4. Reduce to normal temperature, vacuumize (-0.08MPa) and distill under reduced pressure to remove the organic solvent, finally add 0.015 kg of 1,2-benzisothia...

Embodiment 2

[0034] 1. Add 5.6 kg of polycarbonate diol and 0.8 kg of dimethylol butyric acid to the reaction vessel, and feed N 2 protection, stirring and raising the temperature to 75° C., adding 3.6 kg of tetramethylxylylene diisocyanate and reacting for 1.2 hours to prepare prepolymer A.

[0035] 2. Dissolve 0.12 kg of ethylenediamine and 0.8 kg of triethylamine in 27.45 kg of water to form mixed solution B.

[0036] 3. Slowly add the mixed solution B to the prepolymer A, and add 1.6 kg of N-methylpyrrolidone to adjust the viscosity of the emulsion to 14s. Wherein, the addition amount of N-methylpyrrolidone accounts for 4.2% of the total mass of the prepolymer A and the mixed solution B. At room temperature, increase the rotation speed to 2100 rpm, raise the temperature to 42°C, and keep it for 2 hours.

[0037] 4. Reduce to normal temperature, vacuumize (-0.08MPa) and distill under reduced pressure to remove the organic solvent, finally add 0.032 kg of 1,2-benzisothiazol-3-one, stir...

Embodiment 3

[0040] 1. Add 4.8 kilograms of polycaprolactone diols, 4.8 kilograms of polycarbonate diols, and 1.5 kilograms of 1,4-butanediol-2-sodium sulfonate in the reaction vessel, feed N 2 protection, stirring and raising the temperature to 78°C, adding 6 kg of hexamethylene diisocyanate and reacting for 1.5 hours to prepare prepolymer A.

[0041] 2. Dissolve 0.3 kg of hydrazine and 1.5 kg of triethylamine in 38.52 kg of water to form mixed solution B.

[0042] 3. Slowly add the mixed solution B into the prepolymer A, and add 2.52 kg of N-methylpyrrolidone to adjust the viscosity of the emulsion to 16s. Wherein, the addition amount of N-methylpyrrolidone accounts for 4.4% of the total mass of the prepolymer A and the mixed solution B. At room temperature, increase the rotation speed to 2300 rpm, raise the temperature to 43°C, and keep it for 2.2 hours.

[0043] 4. Reduce to normal temperature, vacuumize (-0.08MPa) and distill under reduced pressure to remove the organic solvent, final...

PUM

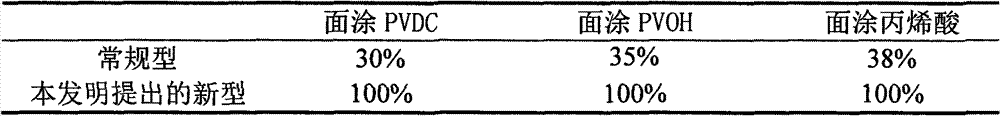

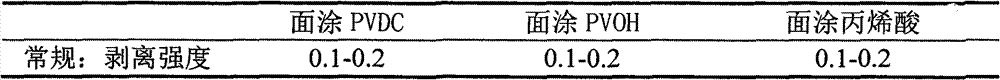

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com