Method for extracting acetoin from fermentation liquor

A technology of acetoin and fermentation liquid, which is applied in the field of biological separation, can solve the problems of difficult separation of acetoin downstream, and achieve the effects of easy regeneration, good adsorption selectivity, and mild desorption conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In the fermented liquid obtained by Fusobacterium acetobutylicum B3 (CGMCC 5234) fermented, the percentage composition of acetoin is 0.2% (w / w), and its fermentation process is as follows: (1) preparation plate culture medium: glucose 10g / L, yeast extract 5g / L, peptone 3g / L, magnesium sulfate heptahydrate 3g / L, ammonium acetate 2g / L, potassium dihydrogen phosphate 1g / L, dipotassium hydrogen phosphate 1g / L, agar 15g / L, at 121 Sterilize at ℃ for 15 minutes. Then the strains were streaked on a solid plate and cultured in a Bugbox anaerobic box (Ruskinn, UK) at 37°C for 24 hours, white irregular colonies grew on the plate. (2) Preparation of seed medium: the same formula as plate medium, but without adding agar. Then pick the bacteria sludge on a plate, inoculate it in 150ml seed medium, and culture it statically at 37°C for 12h. (3) Preparation of fermentation medium: glucose 60g / L, ammonium acetate 2.5g / L, magnesium sulfate heptahydrate 0.5g / L, potassium dihydrogen pho...

Embodiment 2

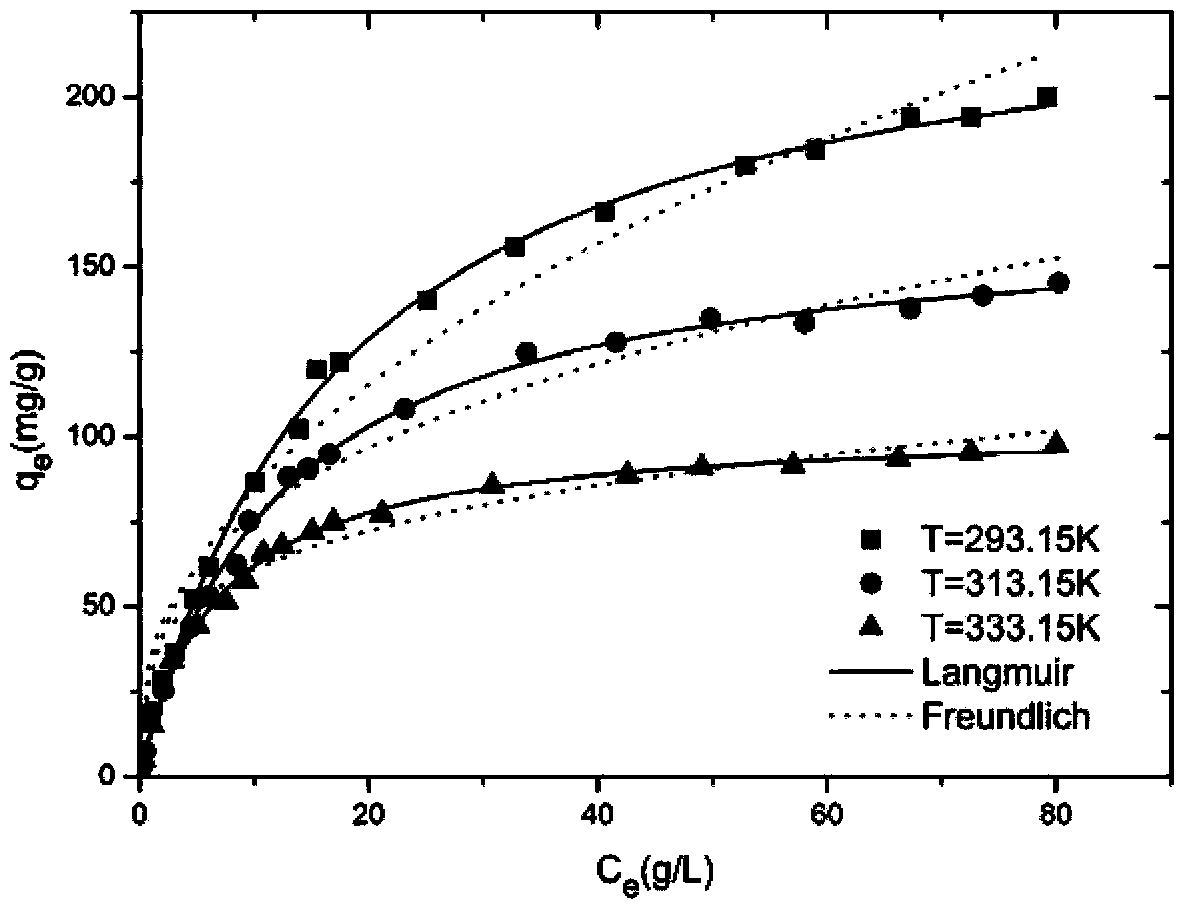

[0042] The fermented liquid obtained in Example 1 is first coarsely filtered, then in a centrifuge at 12000rpm, centrifuged for 2min, and then ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 2000 to 10000 Daltons to remove bacteria and some Miscellaneous protein, at this moment, main components such as acetone, ethanol, butanol, acetoin, acetic acid, butyric acid are contained in the fermented liquid. Pass the obtained fermentation broth through a continuous separation column device equipped with AX-1 macroporous adsorption resin. This device is a four-zone simulated moving bed separation device. pump in for adsorption; the impurity washing area uses deionized water to pump in at a flow rate of 3-20mL / min for impurity washing; the eluting area uses 40%-100% (w / w) methanol solution as the eluent and Pump in at a flow rate of ~25ml / min for elution; in the regeneration zone, use deionized water as a regenerant to pump in at a flow rate of 5~25ml / ...

Embodiment 3

[0044] In a 2000mL three-necked flask, add 200g of dry chloromethylated polystyrene resin, add 1200g of o-nitroethylbenzene, stir and mix, fully swell at room temperature for more than 3h, then add 30g of ferric chloride and stir for 2h, and gradually heat up to 130 ~160°C, carry out Friedel-Crafts post-crosslinking reaction, control the residual chlorine content at 1~2wt%, and stop the reaction. After cooling, suck out the mother liquor, and repeatedly extract the resin with industrial ethanol until the extraction effluent is colorless and clear. Vacuum drying to obtain medium polar ultra-high cross-linked resin HD-02.

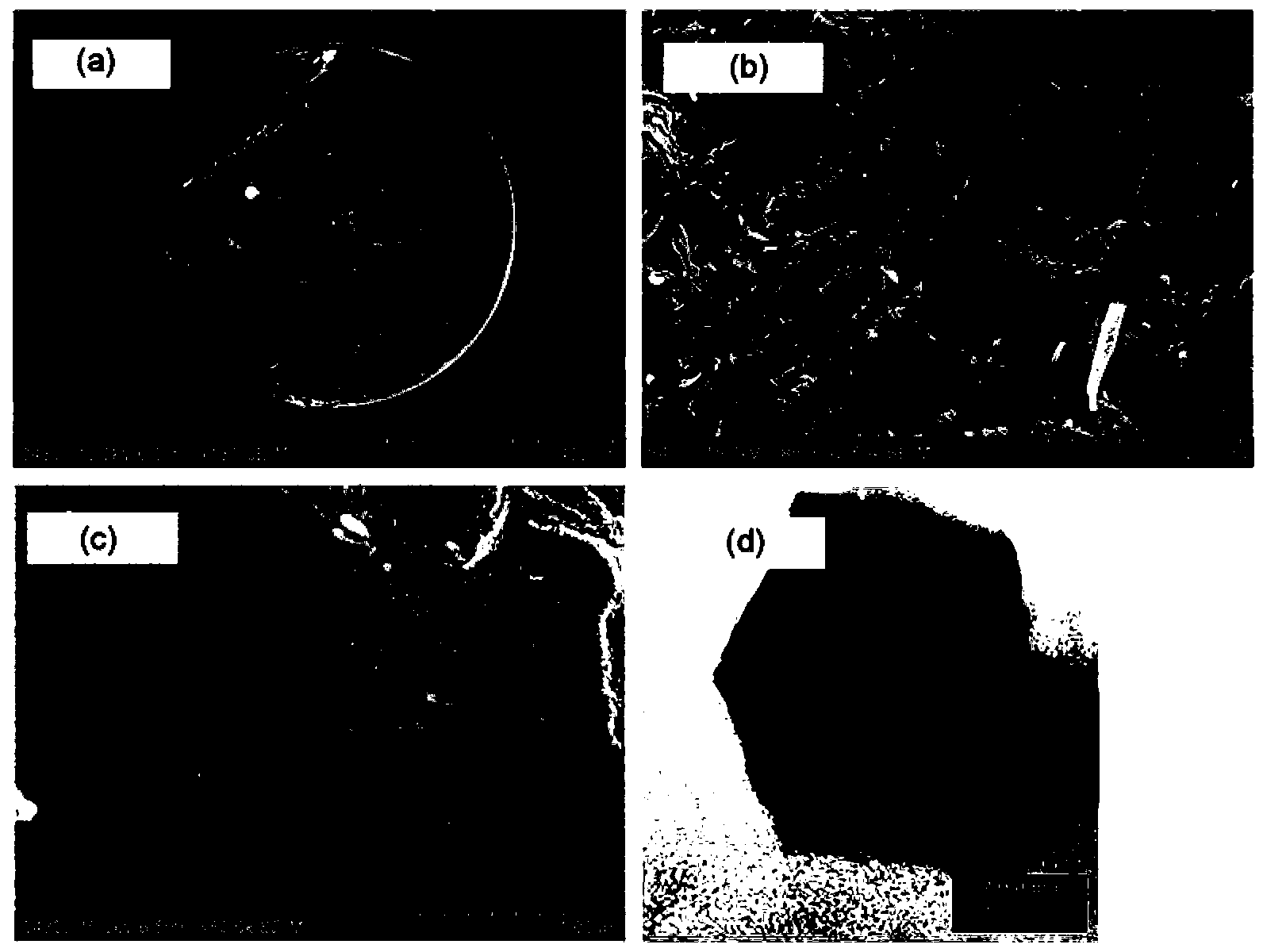

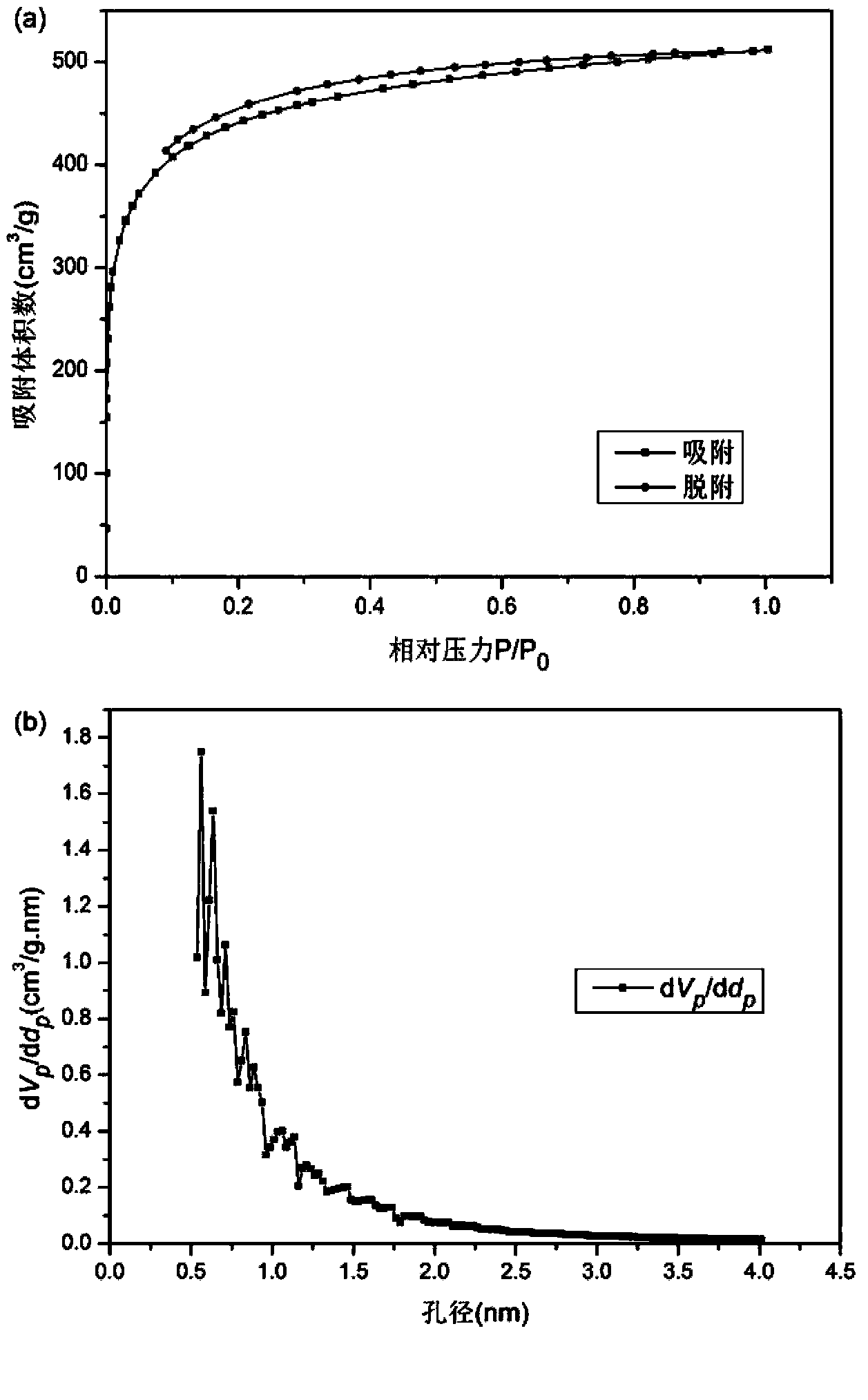

[0045] The obtained product is in the shape of brownish-red round particles, with an average particle size of 0.52mm, a water content of 43%, an average pore size of 1.9nm, and a specific surface area of 1645.5m 2 / g, the average pore volume is 0.796cm 3 / g. The scanning electron micrograph of the synthesized resin is shown in figure 1 , BET diagram (a)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com