Self-control dual-adjustment soldering iron with long service life

A technology of soldering iron and height adjustment, applied in soldering irons, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult simultaneous operation of soldering irons, limited sales scope, and high price of soldering stations, and achieves small occupied space and low cost. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

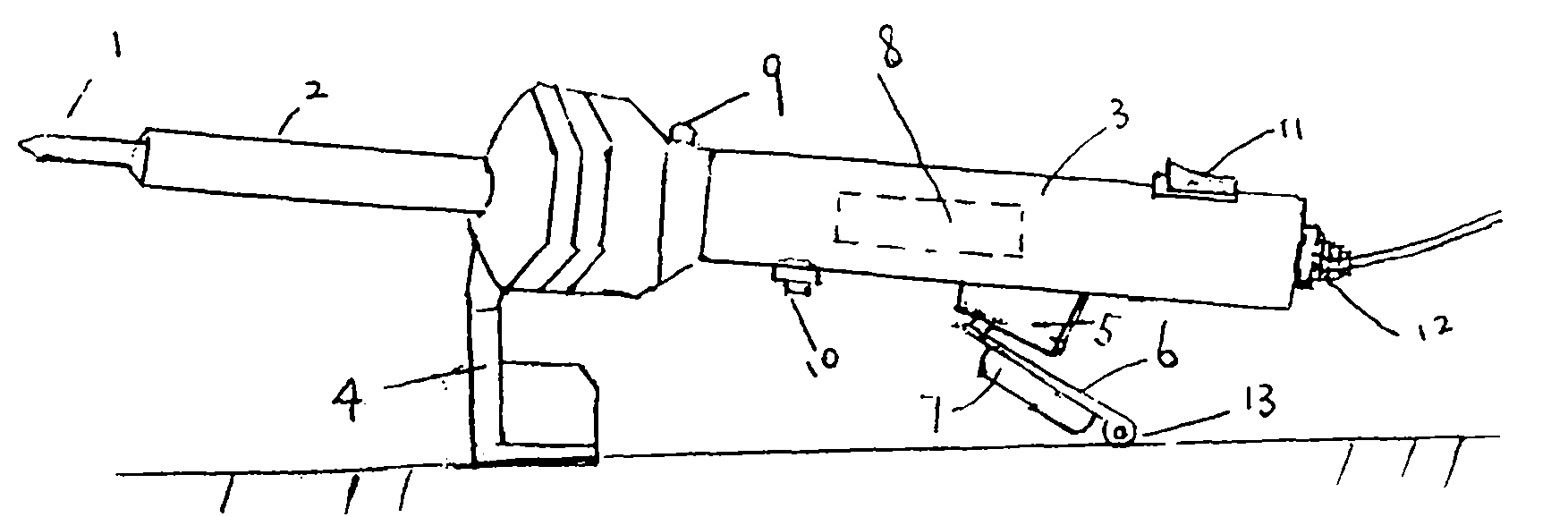

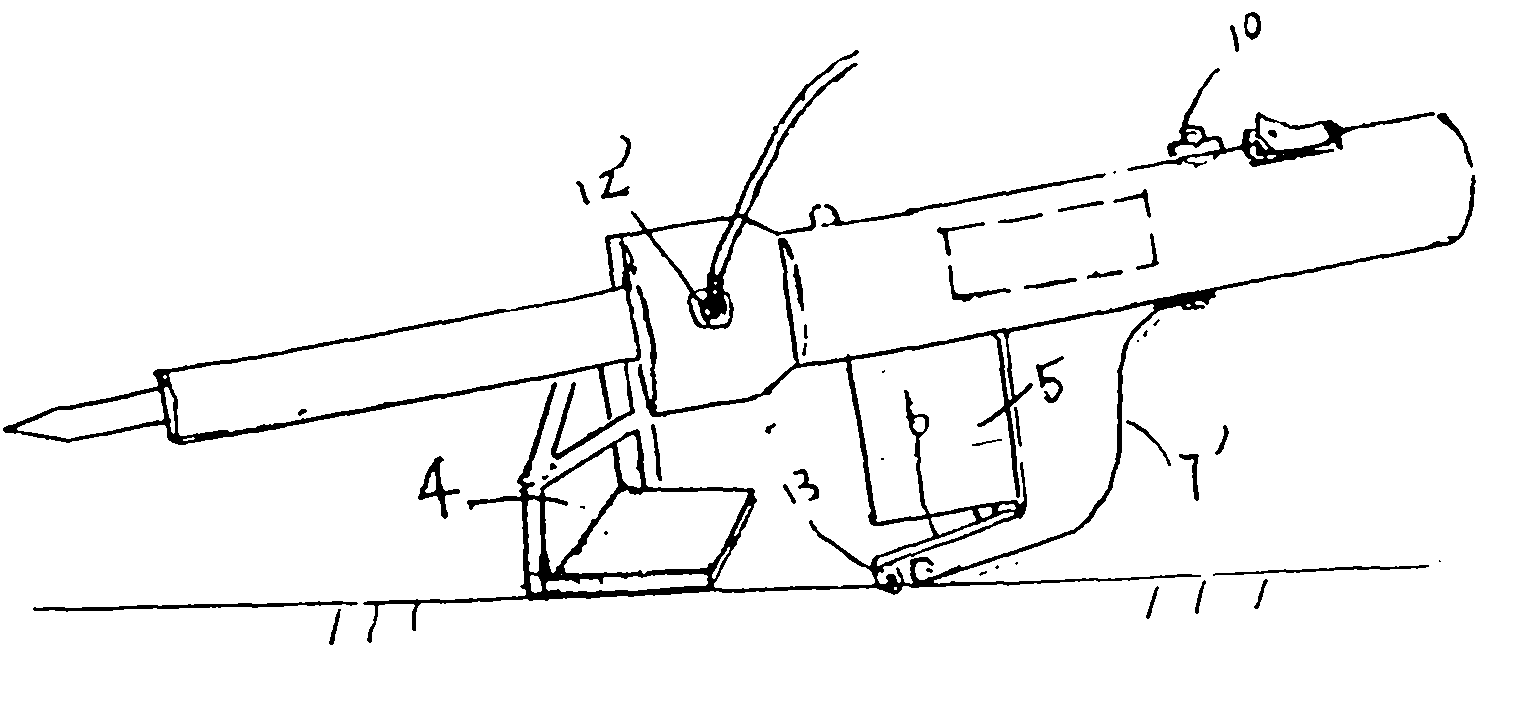

[0029] Example figure 1 with example figure 2 are implemented in the same way.

[0030] When in use, turn on the power switch 11, hold the soldering iron, the micro-switch arm jumps up and then the micro-switch 5 is connected, the control circuit 8 is controlled, the soldering iron works at a high power level (can be preset by the potentiometer 10), and the LED Tube 9 shows red. If welding needs, the microswitch 5 can be turned off by the additional structure 77' that the fingers are close to, and the LED tube 9 shows the color recording. When the soldering iron is placed on the table during the soldering interval, the weight of the soldering iron will press down the lever arm, the soldering iron will work at a low power level, and the LED tube will display the color. If welding is required, the soldering iron will feel slightly lighter when placed on the table, relying on the lever arm 6 The static elastic force, the micro switch 5 remains on, the soldering iron works at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com