Lap brazing gap control device and method for obtaining optimal loading force for brazing

A control device and loading force technology, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve the problems that research and production can not be realized, and achieve the effect of good brazing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

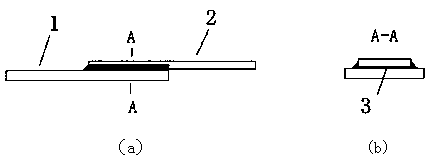

[0045] Such as figure 1 As shown, workpiece one 1 and workpiece two 2 overlap. If the solder piece is not preset, add solder from around the lap joint, and the solder infiltrates the gap 3 of the solder joint through capillary action, so that the gap (solder joint gap) is completely filled with solder. For the brazing overlap of the pre-set solder tab, the solder tab is in a fluid state after melting, and the gap size needs to be controlled by adjusting the loading force. The substantive control methods of the two methods are the same, which is to ensure that the thickness of the brazing joint is at an appropriate value by controlling the loading.

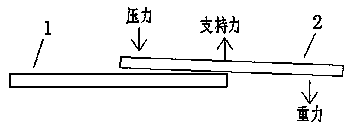

[0046] To ensure the gap, the workpiece must first be clamped. If the workpiece is not rigidly fixed, the gap value at the order of 100 microns will be difficult to control. Especially when the workpiece is long and large, if there is no clamping, the gravity of the workpiece will have a great influence. To keep the workpiece lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com