Polyurethane compositions having improved impact resistance and optical properties

A composition, polyurethane technology, applied in the field of polyurethane and related compositions, which can solve the problems of insufficient optical properties, poor solvent resistance and scratch resistance, unacceptable impact strength and crack resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

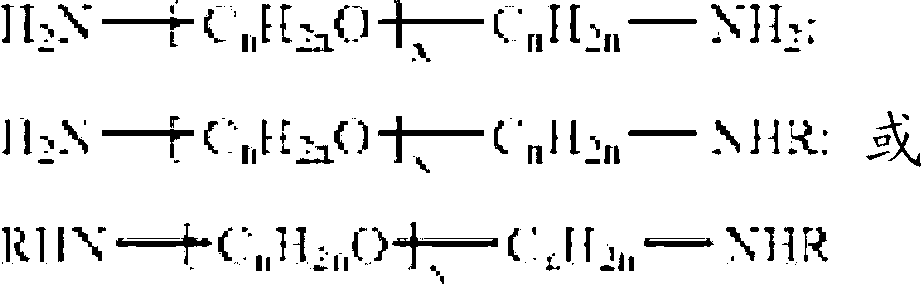

Method used

Image

Examples

Embodiment 1

[0086] Combine, melt and mix well the following: 36.05 grams (g) TONE TM 32B8, 6.83gTONE TM 32C8, 10.63g TONE TM 1278 and 0.58 g trimethylolpropane. This mixture was then added slowly to a three-necked glass flask containing 45.90 g of isocyanate 2 with stirring. Then, the reactor temperature was slowly raised to 90 degrees Celsius (° C.), and the reaction was maintained at 90° C. for 6 hours under a dry nitrogen atmosphere. Finally, the reaction product was a prepolymer with an NCO content of 10.75%.

[0087] Then, the prepolymer reaction product was degassed and cooled to 65°C-70°C, and 100g of the product was mixed with 21.62g of ETHACURE TM 100LC was mixed in a speed mixer for 30 seconds, then poured into molds preheated to 115°C. This forms a sample sheet with a thickness of 3 mm. Then, the mold was placed in an oven set at 115°C. After curing at 115°C for 10 minutes, the sample piece was removed from the mold and post-cured at 115°C for an additional 16 hours....

Embodiment 2

[0090] The prepolymer prepared by another 100g embodiment 1 and 45.45g LONZACURE TM The MCDEA was mixed and then melted on a speed mixer at 100°C for 30 seconds and poured into molds which had been preheated at 130°C. This forms a sample sheet with a thickness of 3 mm. Then, the mold was placed in an oven set at 130°C. After curing at 130°C for 30 minutes, the sample piece was removed from the mold and post-cured at 130°C for an additional 16 hours.

[0091] Then, the sample sheet was kept at room temperature for 7 to 10 days before being subjected to haze, light transmittance, and impact resistance tests. The results are shown in Table 1.

Embodiment 3 and 4

[0105] Examples 3 and 4, and Comparative Examples E and F

[0106] Sample Preparation

[0107] A sample of about 9 millimeters (mm) x 30 mm was cut out from the obtained 3 mm thick test piece. All samples were prepared according to the guidelines of the test method.

[0108]The samples for testing the refractive index were polished to a grit level of 1200 by sandpaper and then several grades of fine paper. The polished samples were tested for refractive index on an Atago DRM2 / 1550 Abbé refractometer at 20°C and various wavelengths. The data were fitted to the Cauchy equation using the "least squares method", and the fitted equation was then used to determine the refractive index at 656.3 nanometers (nm) for each material. Then, calculate the Abbé value for each material according to the following equation:

[0109]

[0110] where n D is the refractive index at 589nm, n C is the refractive index at 656.3nm, and n F is the refractive index at 486nm.

[0111] Using a T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com