Method for manufacturing sodion battery negative pole material and negative pole and sodion battery

A sodium ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as sharp drop in cycle stability, environmental hazards, and capacity fading, and achieve reduced energy consumption, high production efficiency, and simplified The effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

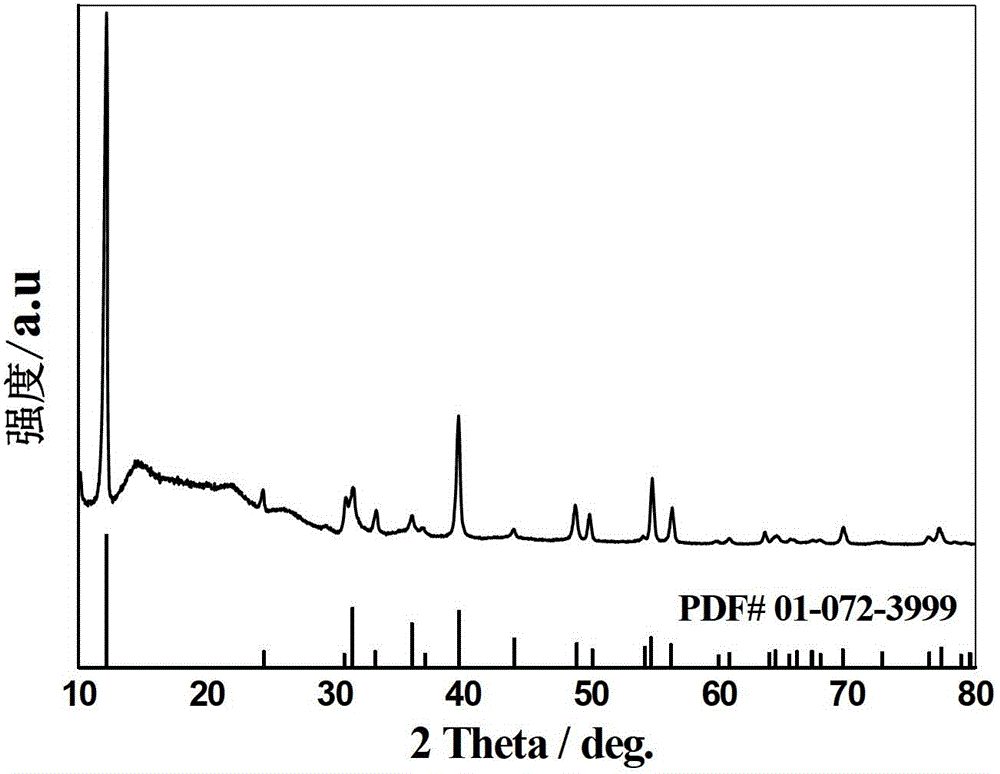

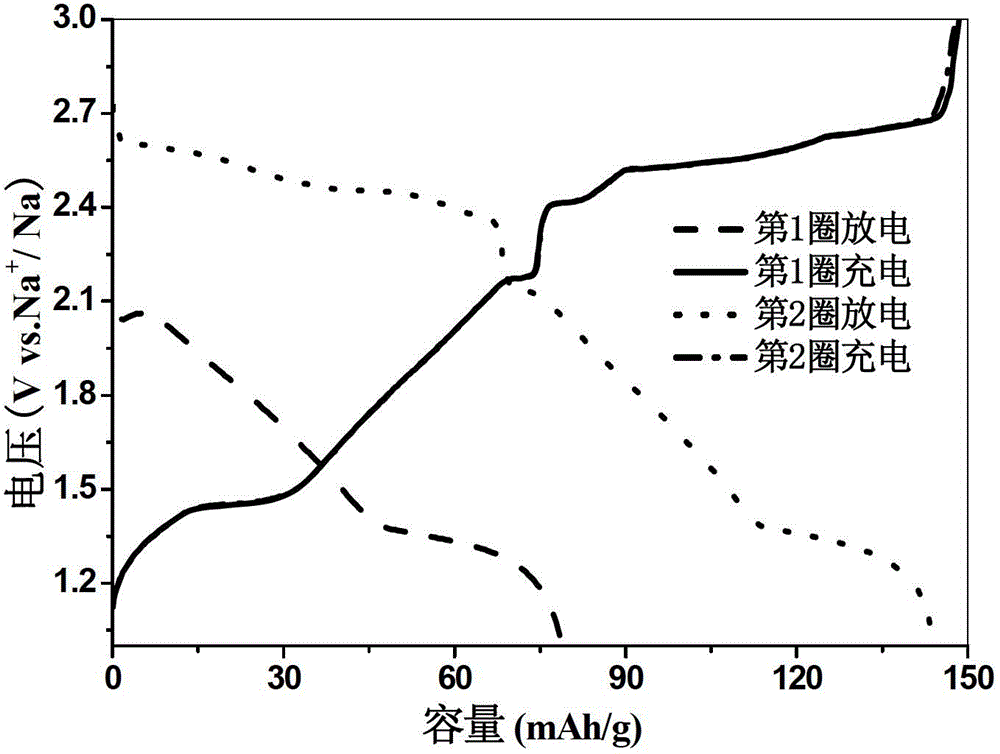

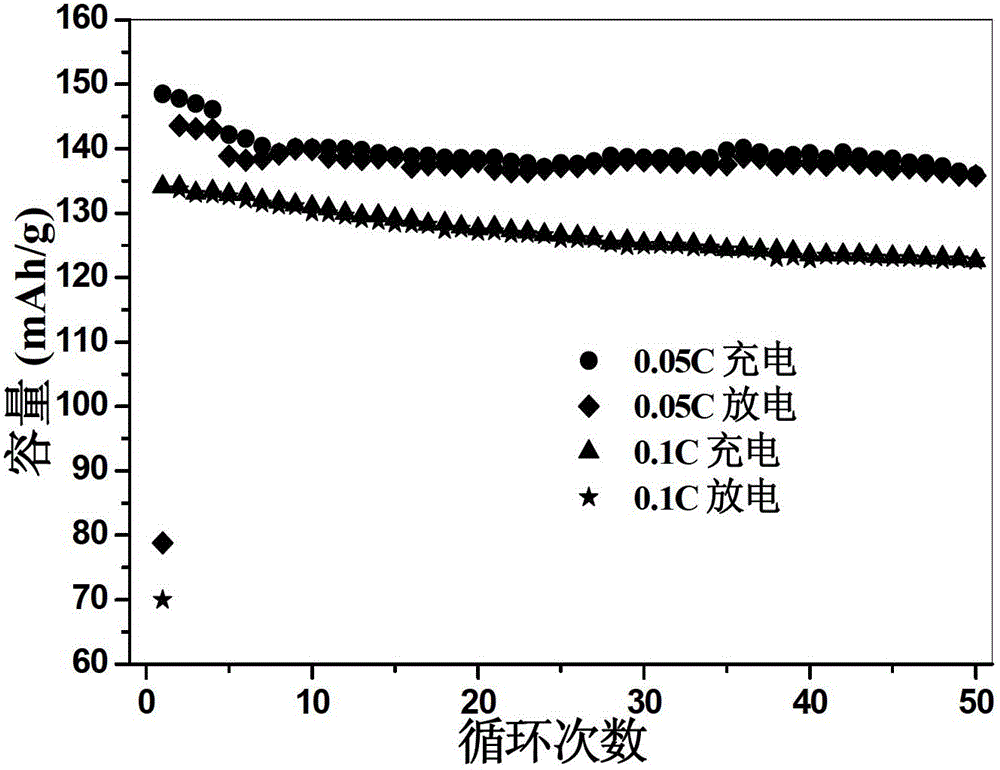

[0042] (1) According to the chemical formula Na 0.5 Nb 2 , Na in the glove box 2 S. Elemental niobium and elemental sulfur are weighed according to the stoichiometric ratio, and they are ground and mixed with an agate mortar for 1 hour. In order to supplement the loss of elemental sulfur during the heating process, an excess of 2wt% elemental sulfur is added before powder grinding, and the powder is mixed uniformly. Put it into a mold, and apply 2 tons of pressure to press it into a highly dense reaction precursor sample, put it into a dried quartz tube, close the valve connected to the opening of the quartz tube, and remove it from the glove box;

[0043] (2) Connect the quartz tube containing the sample in step (1) into a vacuum device. When the vacuum reaches 0.05 Torr, use a mixed flame of acetylene and oxygen to seal the quartz tube, and then place the quartz tube containing the sample Put the tube into the muffle furnace and raise the temperature to 700°C in 20 hours a...

Embodiment 2

[0047] (1) According to the chemical formula Na 0.3 Nb 2 , Na in the glove box 2 S. Elemental niobium and elemental sulfur are weighed according to the stoichiometric ratio, and they are ground and mixed for 1.5 hours with an agate mortar. In order to supplement the loss of elemental sulfur during the heating process, an excess of 3wt% elemental sulfur is added before powder grinding, and the powder is mixed uniformly. Put it into a mold, and apply 3 tons of pressure to press it into a highly dense reaction precursor sample, put it into a dried quartz tube, close the valve connected to the quartz tube, and remove it from the glove box;

[0048] (2) Connect the quartz tube containing the sample in step (1) into a vacuum device. When the vacuum reaches 0.06 Torr, use a mixed flame of acetylene and oxygen to seal the quartz tube, and then place the quartz tube containing the sample Put the tube into the muffle furnace and raise the temperature to 680°C in 15 hours and keep it a...

Embodiment 3

[0052] (1) According to the chemical formula Na 0.25 Nb 2 , Na in the glove box 2 S. Elemental niobium and elemental sulfur are weighed according to the stoichiometric ratio, and they are ground and mixed for 1.5 hours with an agate mortar. In order to supplement the loss of elemental sulfur during the heating process, an excess of 1wt% elemental sulfur is added before powder grinding, and the powder is mixed uniformly. Put it into a mold, and apply 1 ton of pressure to press it into a highly dense reaction precursor sample, put it into a dried quartz tube, close the valve connected to the quartz tube, and remove it from the glove box;

[0053] (2) Connect the quartz tube containing the sample in step (1) into a vacuum device. When the vacuum reaches 0.07 Torr, use a mixed flame of acetylene and oxygen to seal the quartz tube, and then place the quartz tube containing the sample Put the tube into the muffle furnace and raise the temperature to 720°C in 17 hours and keep it a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com