Method for improving uniformity of axial resistivity of czochralski silicon and obtained monocrystalline silicon

A technology of resistivity and uniformity, which is applied in the field of semiconductor materials, can solve the problems of small equilibrium segregation coefficient and poor axial resistivity uniformity of antimony-doped Czochralski single crystal silicon, and achieve the goal of improving uniformity and good industrial application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

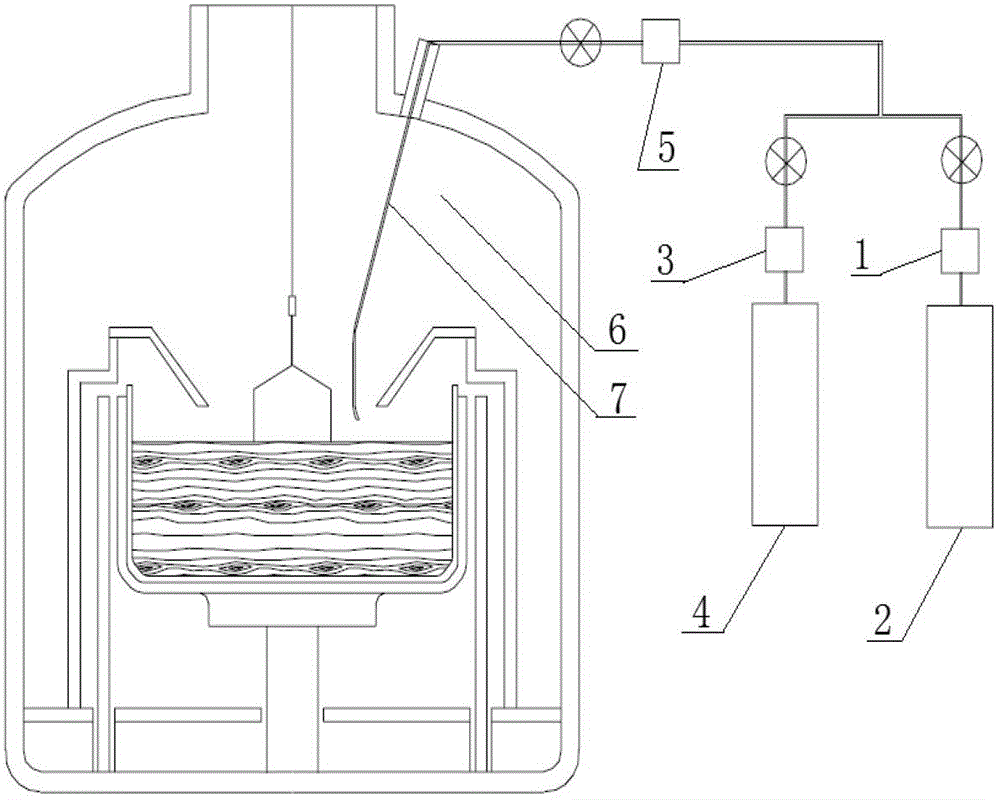

Method used

Image

Examples

Embodiment 1

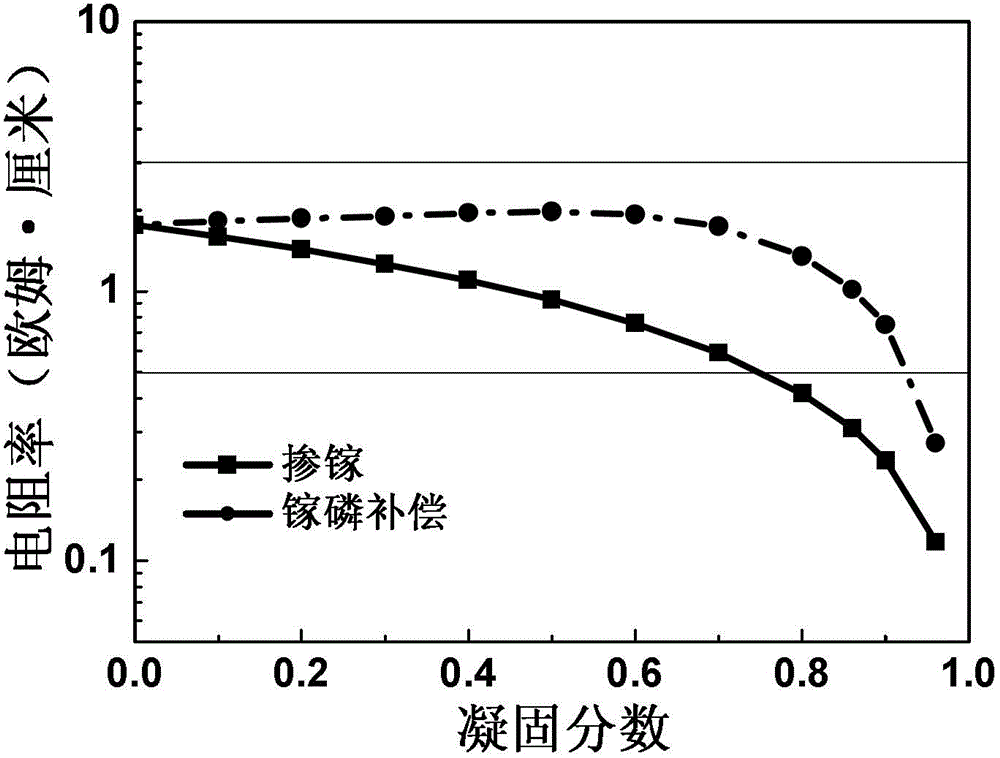

[0065] Add 60kg of high-purity polysilicon raw material into the quartz crucible, and at the same time add 2.982g of high-purity gallium (the target resistivity of the control head is 1.8 ohm.cm).

[0066] Under the protection of argon, the temperature is gradually raised to above 1420°C to completely melt the high-purity polysilicon. According to the conventional crystal growth parameters, the seeding and shouldering are carried out to enter the equal-diameter growth stage, and the crystal pulling rate is controlled to 1.2 mm / min, and the crystal diameter is 150 mm.

[0067] The furnace pressure is controlled to 20 Torr, and the argon gas flow rate is 70 slpm (standard liter per minute).

[0068] Set the parameters for the dopant gas:

[0069] 1) Phosphine diluted with argon is used as the doping gas, and the volume ratio of phosphine to argon is 1:1000;

[0070] 2) Assuming that the doping efficiency is 100% (the impurities introduced by the doping gas can all enter into t...

Embodiment 2

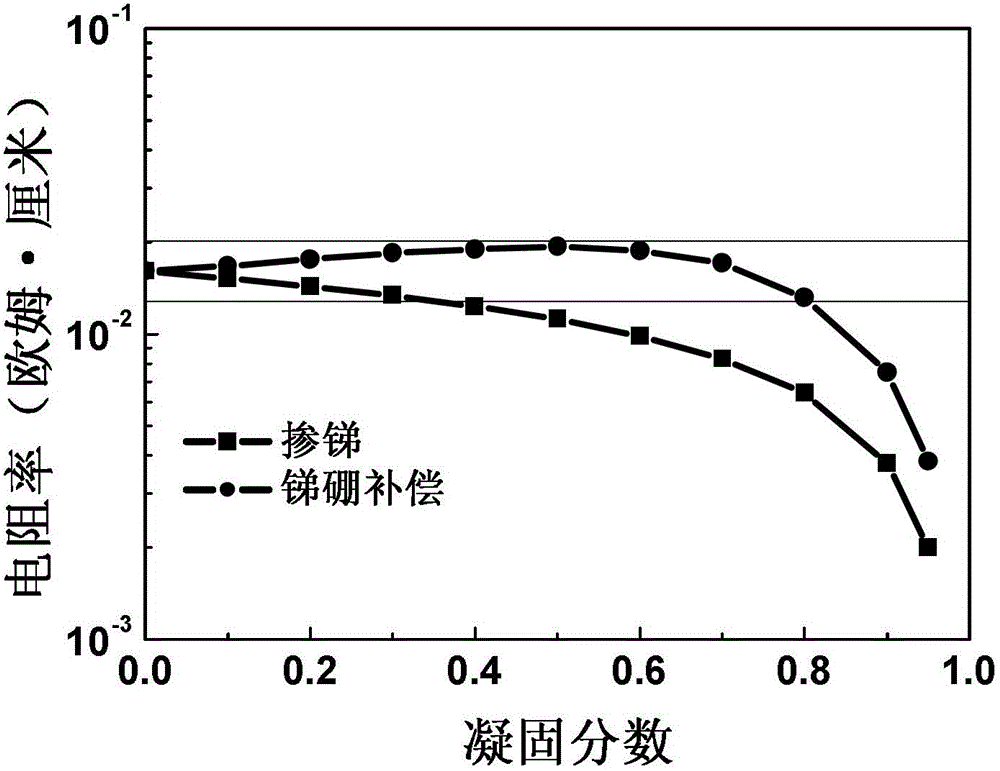

[0075] Add 60 kg of high-purity polysilicon raw material into the quartz crucible, and at the same time add 416.64 g of high-purity antimony (the target resistivity of the control head is 0.016 ohm.cm).

[0076] Under the protection of argon, the temperature is gradually raised to above 1420°C to completely melt the polysilicon. According to the conventional crystal growth parameters, the seeding and shouldering are carried out to enter the equal-diameter growth stage, the crystal pulling rate is controlled to 0.8mm / min, and the crystal diameter is 150mm.

[0077] The furnace pressure is controlled to 20 Torr, and the argon gas flow rate is 70 slpm.

[0078] Set the parameters for the dopant gas:

[0079] 1) Diborane diluted with argon, the volume ratio of diborane to argon is 1:100;

[0080] 2) Assuming that the doping efficiency is 100%, the flow rate of the doping gas is set to 97.58 sccm.

[0081] After the equal-diameter growth is completed, the dopant gas is turned of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com