Preparation method of titanium implant surface with micro-nano composite structure

A technology of micro-nano composite structure and titanium implant is applied in the field of medical material manufacturing, which can solve the problem of few methods for constructing nano-scale structures, and achieve the effect of improving surface biological activity and improving protein adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

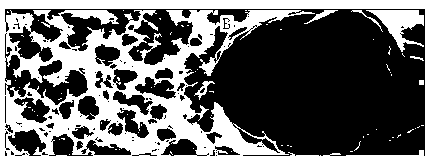

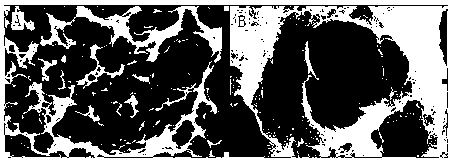

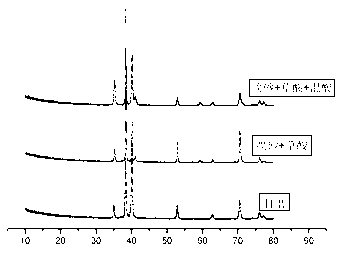

[0017] (1) Sandblasting: use 40~60 mesh emery for titanium implants with a smooth surface, spray evenly for 60 seconds at a pressure of 5 bar, and wash the sprayed implants with acetone, ethanol and pure water under ultrasound for 15 minutes. , Then wash it with plenty of pure water and blow dry with nitrogen. Obtain large ups and downs ranging from ten to ten microns.

[0018] (2) Oxalic acid etching: The implants after sandblasting are directly placed in a fully dissolved oxalic acid solution with a mass concentration of 37.5% in a boiling water bath for 60 minutes, then washed with plenty of water and dried with nitrogen.

[0019] (3) Secondary acid etching: Put the above-mentioned oxalic acid-treated implants into H with a volume ratio of 1:1 2 SO 4 (Mass concentration 98%) and H 2 O 2 In the mixed solution (mass concentration 30%), treat at room temperature for 60 minutes. After the treatment, it is directly washed with a large amount of water to obtain a nano-scale undulatin...

Embodiment 2

[0021] (1) Sandblasting: Use 20-40 mesh emery for the smooth surface of the implants, spray evenly for 60 seconds at a pressure of 5 bar, and wash the sprayed implants with acetone, ethanol and pure water under ultrasound for 15 minutes. Then wash with plenty of pure water and blow dry with nitrogen. Obtain large ups and downs ranging from ten to ten microns.

[0022] (2) Oxalic acid etching: The dried implants are directly placed in a fully dissolved oxalic acid solution with a mass concentration of 37.5% in a boiling water bath for 60 minutes, and washed with a large amount of pure water.

[0023] (3) Secondary acid etching: Put the implants treated above into H with a volume ratio of 1:1 2 SO 4 (Mass concentration 98%) and H 2 O 2 In the mixed solution (mass concentration 30%), treat at room temperature for 90 minutes. After the treatment, it is directly washed with a large amount of water to obtain a nano-scale undulating structure on the original micro-hole structure, thereby...

Embodiment 3

[0025] (1) Sandblasting: Use 80-100 mesh emery for smooth surface implants, spray evenly for 60 seconds under 5 bar pressure, and clean the sprayed implants with acetone, ethanol and pure water under ultrasound for 15 minutes. Then wash with plenty of pure water and blow dry with nitrogen. Obtain large ups and downs ranging from ten to ten microns.

[0026] (2) Oxalic acid etching: The blow-dried implants are directly placed in a fully dissolved oxalic acid solution with a mass concentration of 37.5% in a boiling water bath for 30 minutes, and washed with a large amount of pure water.

[0027] (3) Secondary acid etching: Put the implants treated above into H with a volume ratio of 1:1 2 SO 4 (Mass concentration 98%) and H 2 O 2 In the mixed solution (mass concentration 30%), treat at room temperature for 90 minutes. After the treatment, it is directly washed with a large amount of water to obtain a nano-scale undulating structure on the original micro-hole structure, thereby obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com