Preparation method of titanium implant surface with micro-nano composite structure

A micro-nano composite structure, titanium implant technology, applied in the field of medical material manufacturing, can solve the problem that there are not many methods for constructing nano-scale structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

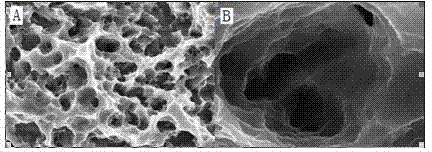

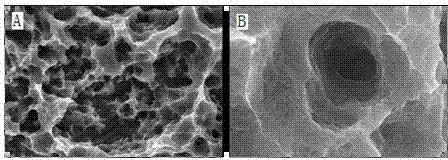

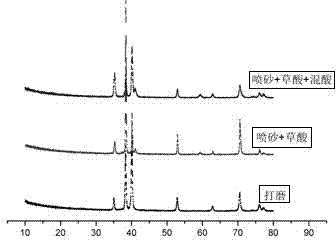

[0017] (1) Sand blasting: 40-60 mesh corundum is used for titanium implants with a smooth surface, and is sprayed evenly for 60 seconds under a pressure of 5 bar. After spraying, the implants are cleaned with acetone, ethanol and pure water under ultrasonic conditions for 15 minutes. , and then washed with a large amount of pure water and blown dry with nitrogen. Obtain large fluctuations of tens of microns to tens of microns.

[0018] (2) Oxalic acid etching: The implants after sand blasting were directly placed in a fully dissolved oxalic acid solution with a mass concentration of 37.5% in a boiling water bath for 60 minutes, then cleaned with a large amount of water, and dried with nitrogen.

[0019] (3) Secondary acid etching: put the above-mentioned oxalic acid-treated implants into H2O with a volume ratio of 1:1 2 SO 4 (mass concentration 98%) and H 2 o 2 (mass concentration 30%) mixed solution, at room temperature for 60 minutes. After the treatment, it is directly...

Embodiment 2

[0021] (1) Sandblasting: The implants with smooth surface are sprayed with 20-40 mesh emery for 60 seconds under the pressure of 5 bar. After spraying, the implants are cleaned with acetone, ethanol and pure water under ultrasonic conditions for 15 minutes. Then wash with a large amount of pure water and blow dry with nitrogen. Obtain large fluctuations of tens of microns to tens of microns.

[0022] (2) Oxalic acid etching: The dried implants were directly placed in a fully dissolved oxalic acid solution with a mass concentration of 37.5% in a boiling water bath for 60 minutes, and cleaned with a large amount of pure water.

[0023] (3) Secondary acid etching: put the implant treated above into H 2 SO 4 (mass concentration 98%) and H 2 o 2 (mass concentration 30%) mixed solution, at room temperature for 90 minutes. After the treatment, it is directly washed with a large amount of water to obtain a nano-scale undulating structure on the original micro-pore structure, ther...

Embodiment 3

[0025] (1) Sand blasting: 80-100 mesh corundum is used for the smooth surface of the implant, and it is evenly sprayed for 60 seconds under the pressure of 5 bar. The sprayed implant is cleaned with acetone, ethanol and pure water under ultrasonic conditions for 15 minutes respectively Then wash with a large amount of pure water and blow dry with nitrogen. Obtain large fluctuations of tens of microns to tens of microns.

[0026] (2) Oxalic acid etching: The dried implants were directly placed in a fully dissolved oxalic acid solution with a mass concentration of 37.5% for 30 minutes in a boiling water bath, and then cleaned with a large amount of pure water.

[0027] (3) Secondary acid etching: put the implant treated above into H 2 SO 4 (mass concentration 98%) and H 2 o 2 (mass concentration 30%) mixed solution, at room temperature for 90 minutes. After the treatment, it is directly washed with a large amount of water to obtain a nano-scale undulating structure on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com