Process for producing bead ferronickel by rotary hearth furnace through coal-based reduction of red soil nickel oxide ores

A technology of nickel oxide ore and rotary hearth furnace, applied in the direction of fluidized bed furnace, etc., can solve the problems of difficult control requirements of rotary kiln, low utilization coefficient of blast furnace, low metal recovery rate, etc., so as to be easy to put into scale production application, The effect of low production cost and high metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

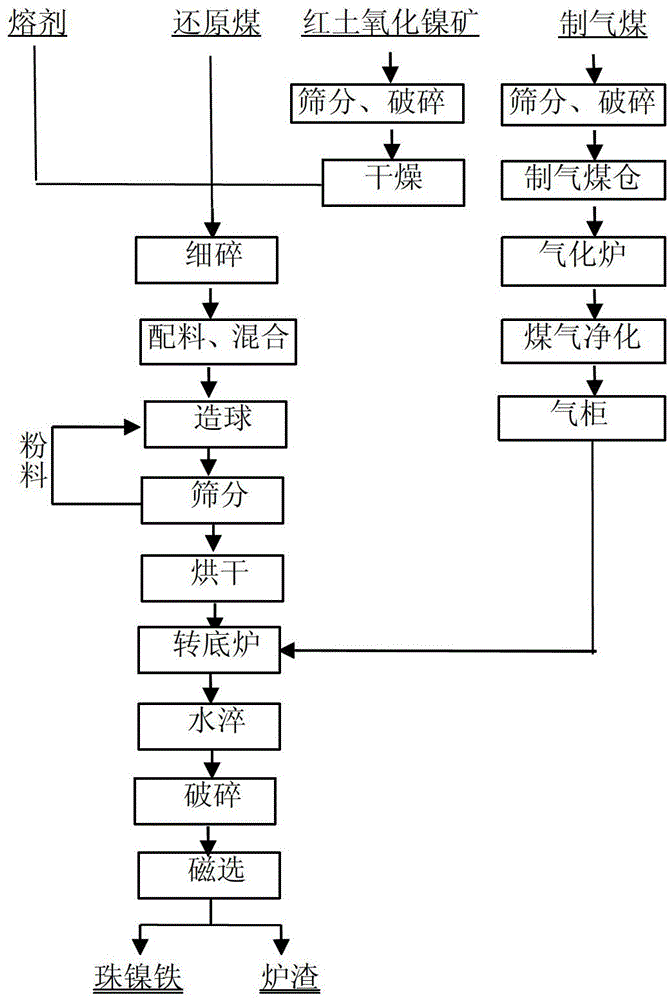

Method used

Image

Examples

Embodiment 1

[0028] Philippine laterite nickel oxide ore (No. 1) composition: Ni1.106%, TFe 48.14%, CaO 2.66%, MgO 3.43%, SiO 2 8.42%, P 0.0037%, coarsely crush the raw ore to less than 100mm, dry at 300°C until the water content is 20%, and then finely crush it to less than 1mm, add 2% fluorite, 31% anthracite, and quicklime to adjust the alkalinity (CaO+ MgO) / SiO 2 0.92, SiO 2 / MgO at 2.4, then mix the materials for 10 minutes and then pelletize. The moisture content of the pellets is 21%. The wet pellets are dried at 250°C for 80 minutes. After drying, they enter the rotary hearth furnace for reduction. For 40 minutes, the product was water quenched and magnetically separated after being released from the furnace. The magnetic separation intensity was 2000 gauss, and the pearl nickel-iron alloy product was obtained. The composition was Ni 2.35%, Fe 92%, Si 0.28%, P 0.014%, C 1.87%, S 0.504 %, the recovery rate of Ni in ferro-pearl reaches 94.62%, and the recovery rate of Fe reaches 84...

Embodiment 2

[0030] Indonesian laterite nickel oxide ore (No. 2) composition: Ni 1.62%, TFe 12.96%, CaO 3.08%, MgO 17.53%, SiO 2 46.59%, P 0.0065%, coarsely crush the raw ore to less than 100mm, dry at 250°C until the water content is 21%, and then finely crush it to less than 1mm, add 2% fluorite, 10% anthracite, and quicklime to adjust the alkalinity (CaO+ MgO) / SiO 2 0.74, SiO 2 / MgO at 2.63, and then mixed for 5 minutes before pelletizing, the moisture content of the pellets was 22%, and the wet pellets were dried at 300°C for 60 minutes. After drying, they entered the rotary hearth furnace for reduction. For 40 minutes, the product was water quenched and magnetically separated after being released from the furnace. The magnetic separation intensity was 3000 gauss, and the pearl nickel-iron alloy product was obtained. The composition was Ni 23.57%, Fe 73%, Si 0.20%, P 0.015%, C 1.71%, S 0.420 %, the recovery rate of Ni in ferro-pearl reaches 90.79%, and the recovery rate of Fe is 33....

Embodiment 3

[0032] Indonesian laterite nickel oxide ore (No. 3) composition: Ni 1.94%, TFe 25.36%, CaO 3.22%, MgO 12.8%, SiO 238.89%, P 0.02%, roughly crush the raw ore to less than 100mm, dry at 300°C until the water content is 19%, and then finely crush it to less than 1mm, add 2% fluorite, 17% anthracite, and quicklime to adjust the alkalinity (CaO+ MgO) / SiO 2 0.71, SiO 2 / MgO at 3.03, then mix the materials for 8 minutes and then pelletize. The moisture content of the pellets is 20%. The wet pellets are dried at 250°C for 60 minutes. After drying, they enter the rotary hearth furnace for reduction. For 40 minutes, the product was water quenched and magnetically separated after being released from the furnace. The magnetic separation intensity was 3000 gauss, and the pearl nickel-iron alloy product was obtained. The composition was Ni 8.57%, Fe 87%, Si 0.25%, P 0.028%, C 1.08%, S 0.643 %, the recovery rate of Ni in ferro-pearl reached 90.18%, and the recovery rate of Fe was 69.03%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com