Method for preparing polylactic acid foaming material subjected to radiation modification by utilizing supercritical fluid CO2

A supercritical fluid and polylactic acid foaming technology, applied in the field of polymer material processing, can solve the problems of difficult control of cell size, low strength of polylactic acid melt and difficult foaming, etc., to achieve uniform cells, low production cost, The effect of increasing the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

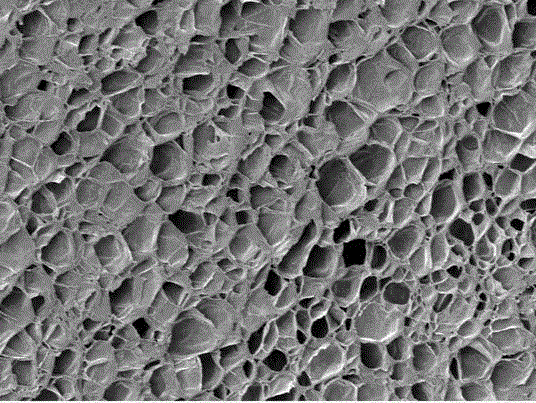

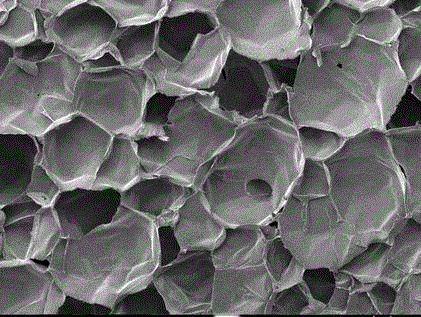

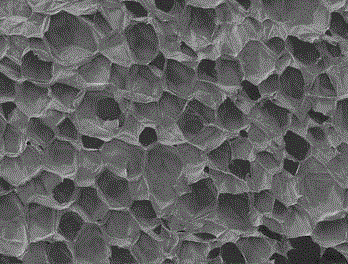

[0042] The viscosity-average relative molecular weight of 100 parts is 2.5×10 5 , L-polylactic acid particles with a melting point of 160°C and 3 parts of sensitizer TAIC relative to the weight of polylactic acid raw materials are melted, blended, extruded and calendered by a twin-screw extruder to make crystallinity below 30%, a certain width, A polylactic acid sheet with a thickness of 2 mm; 60 Co-γ-ray radiation, the absorbed radiation dose is 10kGy. The irradiated polylactic acid sheet was cut into 40mm×40mm test pieces and placed in a mold cavity with a mold temperature of 140°C, and sufficient volume expansion space required for swelling, penetration and nucleation was ensured. First fill with low pressure CO 2 Replace the air in the mold cavity, and then fill it with supercritical fluid CO with a pressure of 10MPa 2 , to carry out swelling and penetration, the swelling and penetration time is 15 minutes, after reaching the diffusion equilibrium, the pressure in the m...

Embodiment 2

[0045] The viscosity-average relative molecular weight of 100 parts is 3.0×10 5 , L-polylactic acid particles with a melting point of 160°C and 3 parts of sensitizer TMPTA relative to the weight of polylactic acid raw materials are melt-blended, extruded and calendered by a twin-screw extruder to make a crystallinity below 30% and a certain width , Polylactic acid sheet with a thickness of 2mm. take the sheet 60 Co-γ-ray radiation, the absorbed radiation dose is 15kGy. The irradiated polylactic acid sheet was cut into 40mm×40mm test pieces and placed in a mold cavity with a mold temperature of 145°C, and sufficient volume expansion space required for swelling, penetration and nucleation was ensured. First fill with low pressure CO 2 Replace the air in the mold cavity, and then fill it with supercritical fluid CO with a pressure of 10MPa 2 , carry out swelling and penetration, the swelling and penetration time is 25min, after reaching the diffusion equilibrium, the pressure...

Embodiment 3

[0048] The viscosity-average relative molecular weight of 100 parts is 2.5×10 5 , L-polylactic acid particles with a melting point of 160°C and a sensitizer PETA of 3 parts relative to the weight of the raw material of polylactic acid are melted, blended, extruded and calendered by a twin-screw extruder to make crystallinity below 30%. , Polylactic acid sheet with a thickness of 2mm. take the sheet 60 Co-γ-ray radiation, the absorbed radiation dose is 10kGy. The irradiated polylactic acid sheet was cut into 40mm×40mm test pieces and placed in a mold cavity with a mold temperature of 155°C, and sufficient volume expansion space required for swelling, penetration and nucleation was ensured. First fill with low pressure CO 2 Replace the air in the mold cavity, and then fill it with supercritical fluid CO with a pressure of 14MPa 2 , carry out swelling and penetration, the swelling and penetration time is 35min, after the diffusion equilibrium is reached, the pressure in the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com