Honeycomb ceramic filter and preparation method thereof

A honeycomb ceramic and filter technology, which is applied in ceramic products, chemical instruments and methods, filtration and separation, etc., can solve the problems of unsatisfactory use temperature, unstable performance, low high temperature strength, etc., and achieve thermal shock stability. Good, strong resistance to chemical attack, low temperature creep rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

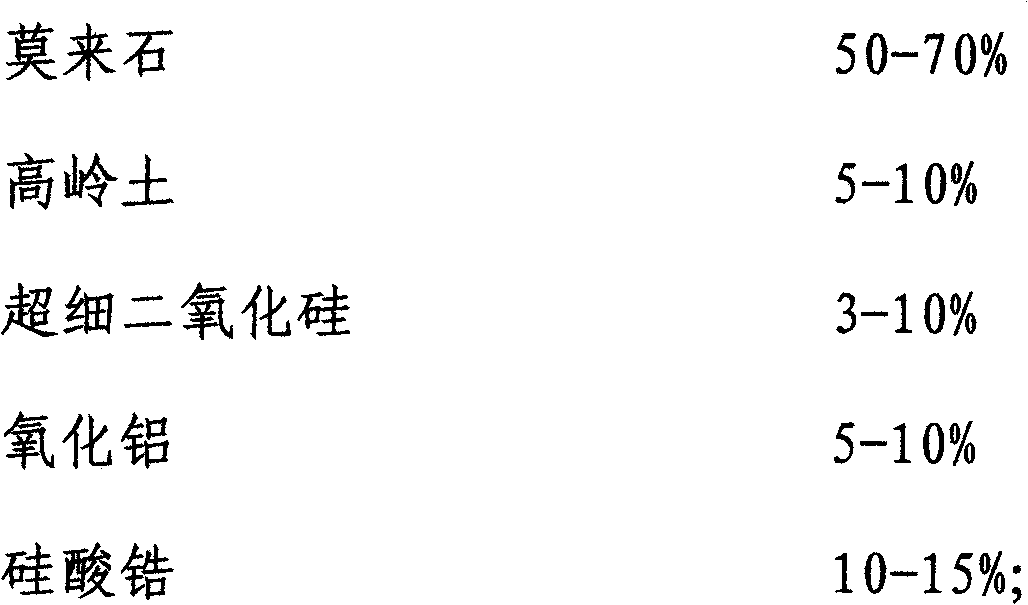

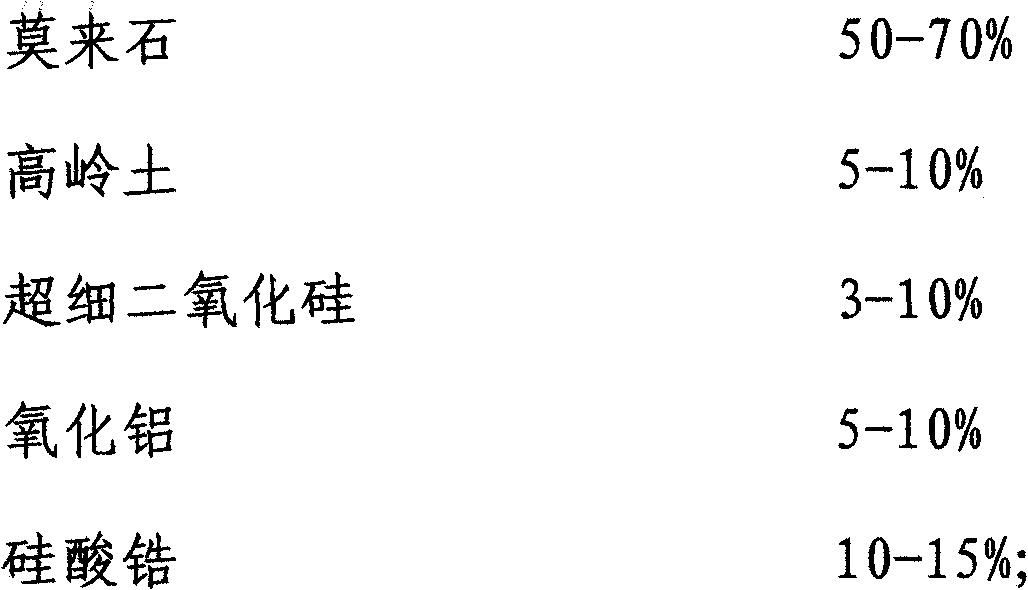

[0050] Firstly, according to the weight ratio of 64:9:8:6:13, mullite, kaolin, ultrafine silica, alumina and zirconium silicate are fully mixed to form ceramic powder.

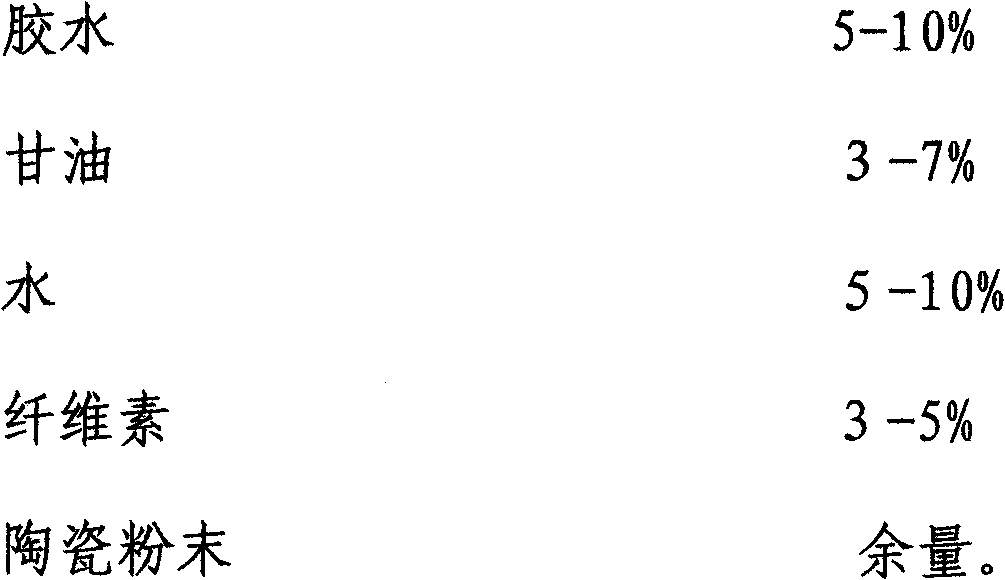

[0051] Next, mix the ceramic powder, glue, glycerin, water, and cellulose according to the weight ratio of 75:8:5:8:4, put them into a mixer and stir for 1 hour to make it evenly stirred to make plastic mud.

[0052] The plastic mud is roughed and refined by a mud refining machine, then processed by a vacuum machine, and extruded by a mold in a molding machine to form a ceramic filter blank.

[0053]Put the ceramic filter body into a microwave oven for finalization, then send it into a drying room, control the temperature within the range of 100-110°C, dry it for 24 hours to harden it, and slice the dried body to obtain a neat Honeycomb filter.

[0054] Put the processed complete honeycomb ceramic body into the sintering furnace, heat up to 550°C at a heating rate of 60°C / h for low-temperature debinding, and ...

Embodiment 2

[0056] First, according to the weight ratio of 62:8:9:7:14, mullite, kaolin, ultrafine silica, alumina, and zirconium silicate are fully mixed to form ceramic powder.

[0057] Next, mix the ceramic powder, glue, glycerin, water, and cellulose according to the weight ratio of 73:8:5:10:4, put them into a mixer and stir for 1 hour to make it evenly stirred to make ceramic mud.

[0058] Then, the ceramic mud is roughly refined and refined by a mud refining machine, and processed by a vacuum machine, and the extrusion molding process is adopted, and the ceramic body is extruded through a mold in a molding machine.

[0059] Put the ceramic filter blank into microwave shape, and then send it into the drying room. The temperature is controlled in the range of 100-110°C, and it is dried for 24 hours to harden. The dried blank is sliced to obtain a neat honeycomb filter. device.

[0060] Put the processed complete honeycomb ceramic body into the sintering furnace, heat up to 550°C a...

Embodiment 3

[0062] Firstly, according to the weight ratio of 63:10:9:8:10, mullite, kaolin, ultrafine silica, alumina and zirconium silicate are fully mixed to form ceramic powder.

[0063] Next, mix the ceramic powder, glue, glycerin, water, and cellulose according to the weight ratio of 72:9:7:9:4, put them into a mixer and stir for 1 hour to make the stirring even, and make ceramic mud.

[0064] Then, the ceramic mud is roughly refined and refined by a mud refining machine, and processed by a vacuum machine, and the extrusion molding process is adopted, and the ceramic body is extruded through a mold in a molding machine.

[0065] Put the ceramic filter blank into microwave shape, and then send it into the drying room. The temperature is controlled in the range of 100-110°C, and it is dried for 24 hours to harden. The dried blank is sliced to obtain a neat honeycomb filter. The body of the device.

[0066] Put the processed complete honeycomb ceramic body into the sintering furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com