Preparation process of YMnO3 dielectric ceramic and YMnO3 dielectric ceramic capacitor

A ceramic capacitor and preparation technology, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, etc., can solve the problems of long sintering time, incomplete reaction, high sintering temperature of high-density ceramics, etc., and achieve low degree of particle agglomeration , Low production cost, and the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] The specific embodiment of the present invention is set forth in detail below: YMnO 3 The preparation process of dielectric ceramics comprises the following steps:

[0027] Step 1, take by weighing the Y (NO 3 ) 3 ·6H 2 O and 99.5% pure Mn(CH 3 COO) 2 4H 2 O mixed into the container, added deionized water, then fully dissolved and stirred evenly by a magnetic stirrer, the solution concentration was adjusted to 0.2mol / L, after continuing to stir for 4h, set aside;

[0028] Step 2, in step 1 gained solution, add the C that is 99% the purity that is equimolar with solution metal ion total amount 6 h 8 o 7 ·H 2 0, and adjust the pH value of the solution to 5-6 with ammonia water. After stirring for 24 hours, the solution was evaporated in an oil bath at 120°C to obtain a fluffy block solid, and the obtained block solid was ground into powder and put into a crucible. Keep warm at 300°C for 3 hours, then naturally cool to room temperature and take out the obtained p...

Embodiment 1

[0042] YMnO 3 The preparation process of dielectric ceramics comprises the following steps:

[0043] Step 1, take by weighing the Y (NO 3 ) 3 ·6H 2 O and 99.5% pure Mn(CH 3 COO) 2 4H 2 O mixed into the container, added deionized water, then fully dissolved and stirred evenly by a magnetic stirrer, the solution concentration was adjusted to 0.2mol / L, after continuing to stir for 4h, set aside;

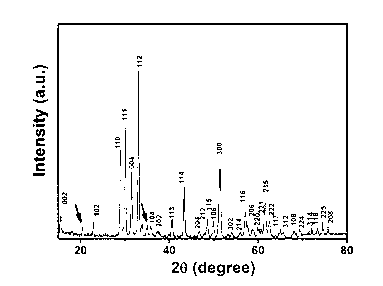

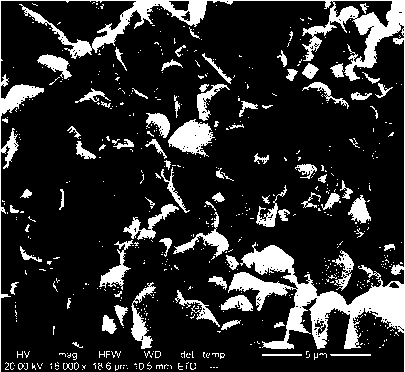

[0044] Step 2, in step 1 gained solution, add the C that is 99% the purity that is equimolar with solution metal ion total amount 6 h 8 o 7 ·H 2 O, and adjust the pH value of the solution to 5 with ammonia water, after stirring for 24 hours, evaporate the solution through an oil bath at 120°C to obtain a fluffy block solid, grind the obtained block solid into powder, put it into a crucible, and heat up to 300°C After heat preservation for 3 hours, then naturally cool to room temperature and take out the obtained powder, and add silicon dioxide with a purity of 1 / 10,000 of the ...

Embodiment 2

[0054] YMnO 3 The preparation technology of dielectric ceramics is characterized in that: comprising the following steps:

[0055] Step 1, take by weighing the Y (NO 3 ) 3 ·6H 2 O and 99.5% pure Mn(CH 3 COO) 2 4H 2 O mixed into the container, added deionized water, then fully dissolved and stirred evenly by a magnetic stirrer, the solution concentration was adjusted to 0.2mol / L, after continuing to stir for 4h, set aside;

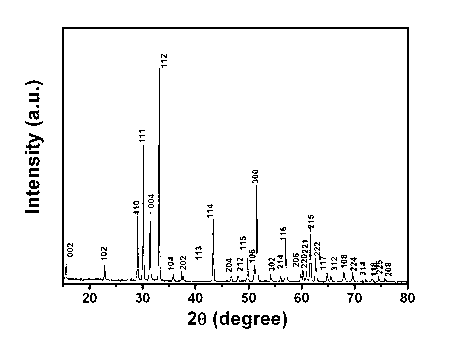

[0056] Step 2, in step 1 gained solution, add the C that is 99% the purity that is equimolar with solution metal ion total amount 6 h 8 o 7 ·H 2 O, and adjust the pH value of the solution to 6 with ammonia water. After stirring for 24 hours, evaporate the solution through an oil bath at 120°C to obtain a fluffy block solid. Grind the obtained block solid into powder, put it into a crucible, and heat up to 300°C. After heat preservation for 3 hours, then naturally cool to room temperature and take out the obtained powder, and add silicon dioxide wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com