Double-region device for efficiently recovering yellow phosphorus combustion heat

A two-zone, high-efficiency technology, applied in the directions of phosphorus oxides, phosphoric acid, phosphorus oxyacids, etc., can solve the problems of low temperature waste heat that cannot be effectively recovered and limited, and meet the requirements of improving energy utilization efficiency and reducing cooling. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

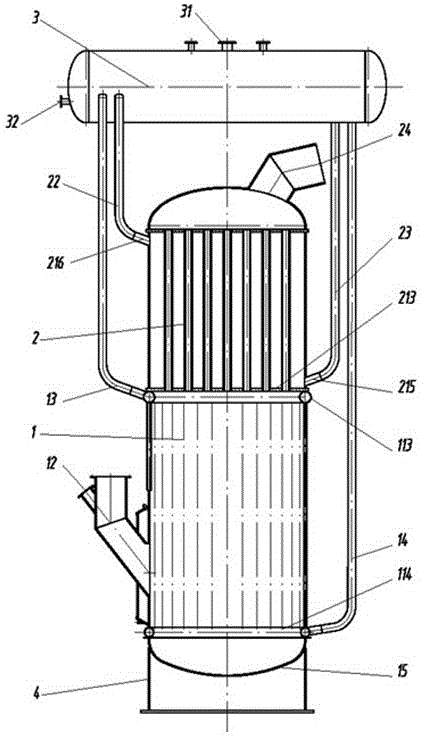

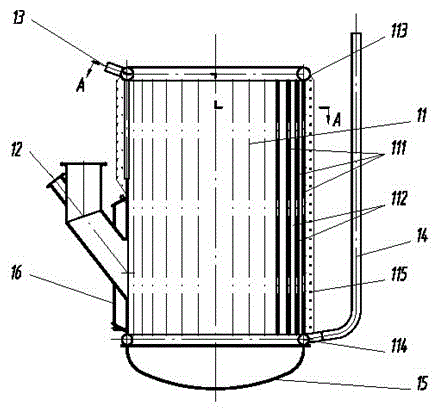

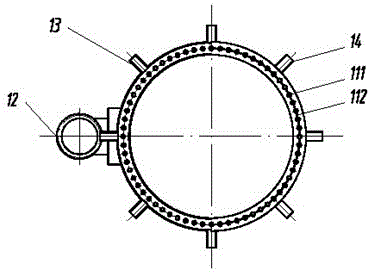

[0020] Such as figure 1 As shown, the whole device of the present invention includes support 4, full combustion zone assembly 1, convection heat transfer zone assembly 2 and steam drum 3 from bottom to top; The other end of the downcomer 14 communicates with the lower header 114 of the full combustion zone assembly 1; one end of the water vapor guide pipe 13 in the full combustion zone communicates with the steam drum 3, and the other end of the water vapor guide tube 13 in the full combustion zone communicates with the full combustion zone The upper header 113 of the zone assembly 1 communicates; one end of the downcomer 23 in the convection heat transfer zone communicates with the steam drum 3, and the other end of the downcomer 23 in the convection heat transfer zone communicates with the cooling water inlet pipe 215 in the convection heat transfer zone component 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com