Scheelite beneficiation method

A technology of scheelite beneficiation and scheelite, applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve the problems of low recovery rate of scheelite, low grinding efficiency, over-grinding, etc., and achieve mature process principles and reduce Over-grinding situation, technological process to achieve easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

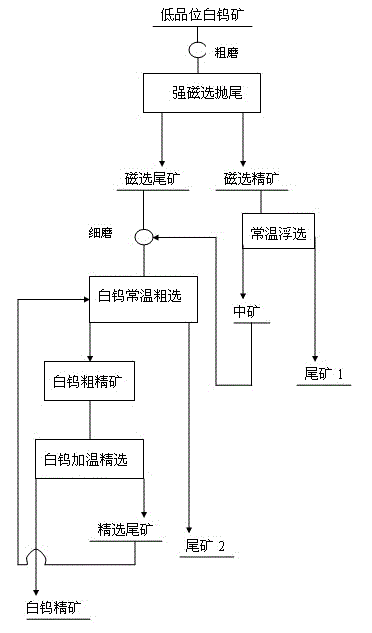

[0021] Coarse grinding of raw ore without desliming. After passing through a 200-250μm vibrating screen, the sieve is returned to the coarse grinding, and the ore under the sieve is subjected to strong magnetic separation and tailing, mainly to throw away magnetic garnet and other magnetic minerals. After grinding, it enters scheelite normal temperature flotation. The concentrate obtained by rough selection is subjected to a scheelite heating and selection to obtain scheelite concentrate; the tailing magnetic separation concentrate is also subjected to normal temperature flotation. The medium ore is merged into non-magnetic scheelite for fine grinding;

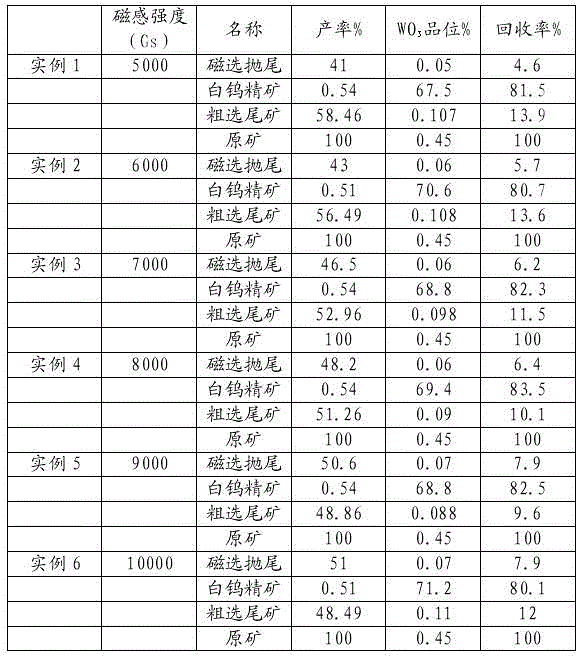

[0022] Strong magnetic separation and tailings: After the low-grade scheelite raw ore is coarsely ground and screened by a 200-250μm vibrating screen, the sieve returns to coarse grinding, and the material under the sieve is subjected to a magnetic induction intensity of 5000Gs to obtain magnetic separation tailings and magneti...

Embodiment 2

[0027] Coarse grinding of raw ore without desliming. After passing through a 200-250μm vibrating screen, the sieve is returned to the coarse grinding, and the ore under the sieve is subjected to strong magnetic separation and tailing, mainly to throw away magnetic garnet and other magnetic minerals. After grinding, it enters scheelite normal temperature flotation. The concentrate obtained by rough selection is subjected to a scheelite heating and selection to obtain scheelite concentrate; the tailing magnetic separation concentrate is also subjected to normal temperature flotation. The medium ore is merged into non-magnetic scheelite for fine grinding;

[0028] Strong magnetic separation and tailings: After the low-grade scheelite raw ore is coarsely ground and screened by a 200-250μm vibrating screen, the sieve returns to the coarse grinding, and the material under the sieve gets magnetic separation tailings and magnetic separation concentrate under the magnetic induction inte...

Embodiment 3

[0033] Coarse grinding of raw ore without desliming. After passing through a 200-250μm vibrating screen, the sieve is returned to the coarse grinding, and the ore under the sieve is subjected to strong magnetic separation and tailing, mainly to throw away magnetic garnet and other magnetic minerals. After grinding, it enters scheelite normal temperature flotation. The concentrate obtained by rough selection is subjected to a scheelite heating and selection to obtain scheelite concentrate; the tailing magnetic separation concentrate is also subjected to normal temperature flotation. The medium ore is merged into non-magnetic scheelite for fine grinding;

[0034] Strong magnetic separation and tailing: After the low-grade scheelite raw ore is coarsely ground and sieved by a 200-250μm vibrating sieve, the sieve returns to coarse grinding, and the material under the sieve is subjected to magnetic induction of 7000Gs to obtain magnetic separation tailings and magnetic separation con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com