Free-cutting stainless-steel material for precision processing and process for producing same

A technology of precision machining and manufacturing methods, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of undisclosed surface roughness, undisclosed surface properties, corrosion resistance and free-cutting stainless steel raw materials, etc., to meet environmental friendliness, Realize the effect of electrical energy consumption and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

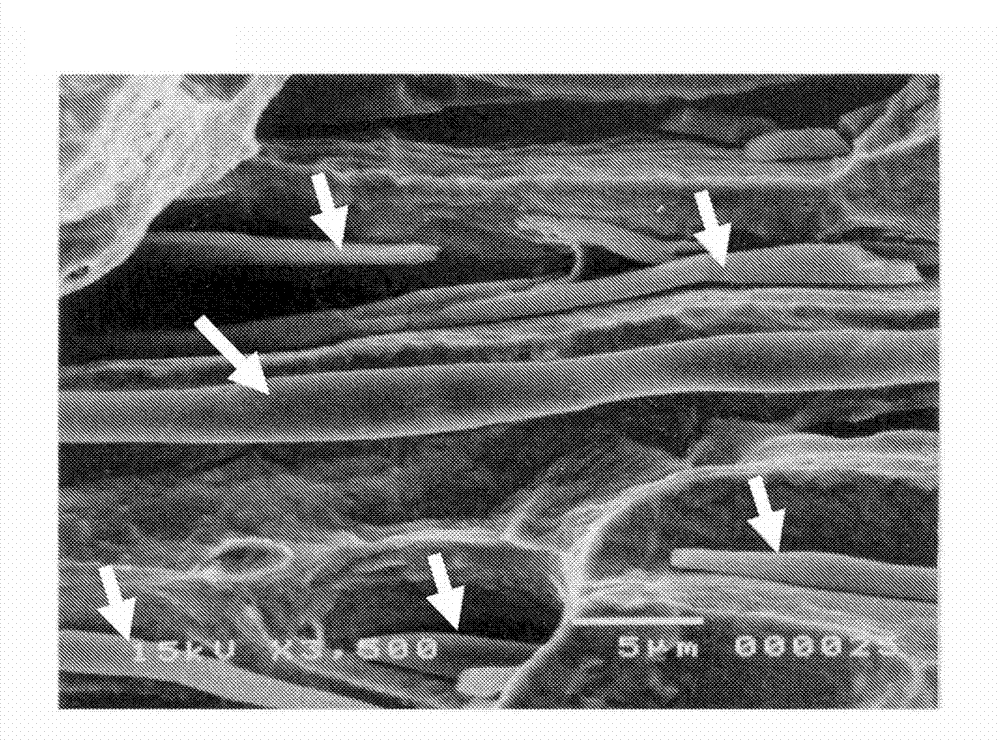

[0032] (Example 1) A commercially available austenitic stainless steel (SUS304) round bar (weight 2 kg) was used as a melting raw material, and was melted using a water-cooled crucible suspension melting furnace (Japanese: Koldkuru-shibur floating melting furnace). The component composition (mass %) of the molten raw material was 0.06% C, 0.28% Si, 1.33% Mn, 0.035% P, 0.025% S, 8.05% Ni, and 18.39% Cr. During melting, N was sealed in the vacuum induction melting furnace at 0.07 MPa to adjust the N concentration in the molten steel. After melting, add a specified amount of commercially available ferroboron (19.2 mass% B) to the molten metal, adjust the B concentration, melt in a weakly reduced pressure N atmosphere, and then keep it at 1600°C for 10 minutes, and then cool it in water. solidified in a crucible to make ingots. The ingot was forged and rolled at 1200° C., processed into a 14 mm square bar, and air-cooled. The bar was subjected to water cooling after holding at 125...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com