Method for forming SOI MOSFET (Silicon On Insulator Metal-Oxide-Semiconductor Field Effect Transistor) body contact by using side wall process

A body contact and process technology, applied in the field of forming electronic components, can solve the problems of destroying the isolation effect of SOIMOSFET devices, complicating the device manufacturing process, reducing production costs, etc., to achieve anti-floating body effect, prevent self-heating effect, increase Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing example:

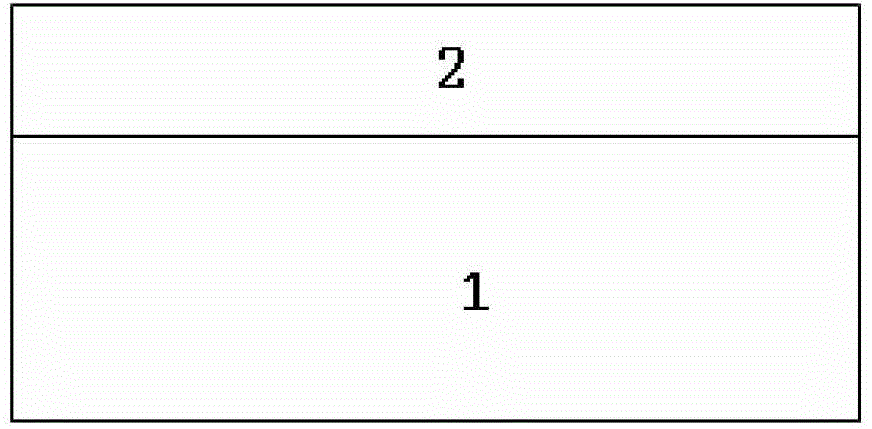

[0034] combine figure 1 . A masking film 2 is shown deposited on an underlying semiconductor substrate 1 . The material of the underlying semiconductor substrate 1 can be freely selected, for example: silicon, germanium, group III~V compound semiconductor materials, group II~VI compound semiconductor materials or other compound semiconductor materials, etc., and single crystal materials can also be used. For single crystal materials It can also be made into an n-type substrate or a p-type substrate by doping. The material used for the masking film 2 can be such as SiO 2 The same hard masking material can also be applied with a soft masking material like photoresist, but no matter which type of masking material is used, it should be noted that the material used for the masking film cannot be the same as the underlying semiconductor substrate material to prevent etchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com