Long glass fiber reinforced electrically and thermally conductive polyphenylene sulfide composite material and preparation method thereof

A composite material, polyphenylene sulfide technology, applied in the direction of coating, etc., to achieve the effect of easy process control, simple formula and consistent arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

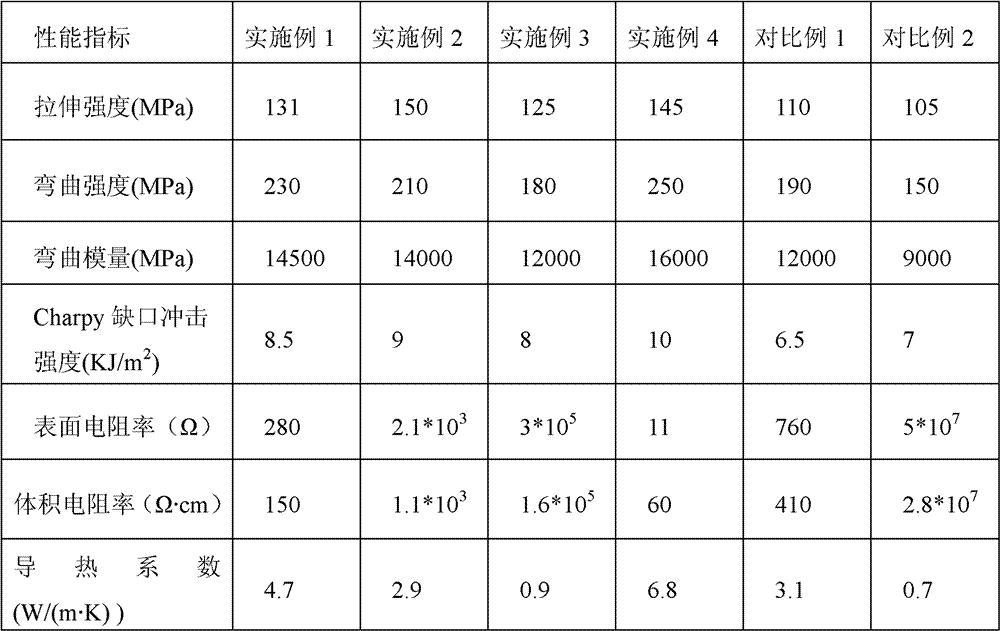

Embodiment 1

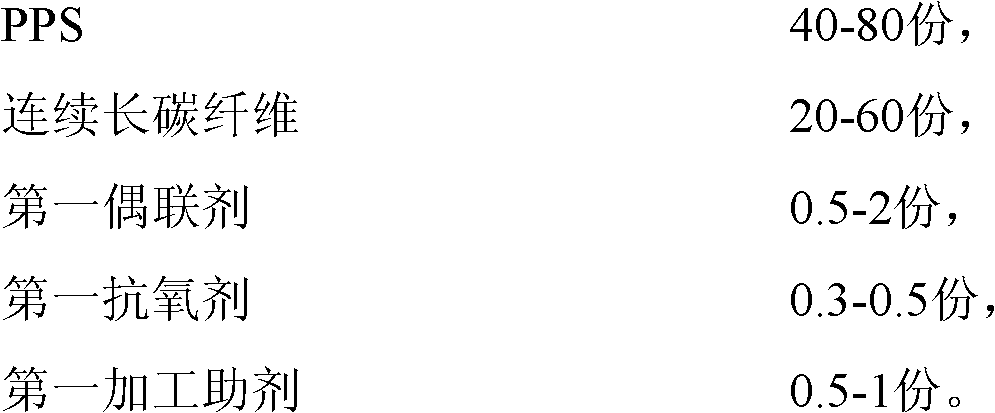

[0038] Adopt pultrusion method to make 40 parts (parts by weight, the same below) PPS resin, PPS is cross-linked polyphenylene sulfide, and the weight average molecular weight is greater than 3.0*10 5 , 60 parts of continuous long carbon fiber (pitch-based carbon fiber filament), 0.5 part of silane coupling agent KH590, 0.3 part of antioxidant (composed of 0.15 part of antioxidant 1010, 0.15 part of antioxidant 168), 0.5 part of silicone powder Made of long carbon fiber reinforced PPS resin masterbatch;

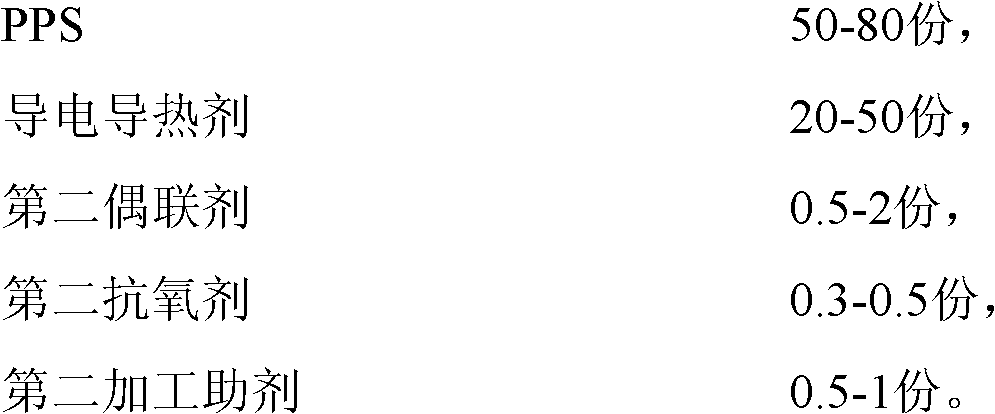

[0039] 50 parts of PPS resin, PPS is cross-linked polyphenylene sulfide, the weight average molecular weight is greater than 3.0*10 5 , 50 parts of high thermal conductivity graphite, 0.5 parts of silane coupling agent KH590, 0.3 parts of antioxidant (composed of 0.15 parts of antioxidant 1010, 0.15 parts of antioxidant 168), 0.5 parts of silicone powder, 0.5 parts of oxidized polyethylene wax Mix evenly, extrude and granulate through a twin-screw extruder to make conductive...

Embodiment 2

[0044] Adopt pultrusion method to make 60 parts (parts by weight, the same below) PPS resin, PPS is cross-linked polyphenylene sulfide, and the weight average molecular weight is greater than 3.0*10 5 , 40 parts of continuous long carbon fiber (pitch-based carbon fiber filament), 0.5 part of silane coupling agent KH590, 0.4 part of antioxidant (composed of 0.2 part of antioxidant 1098, 0.2 part of antioxidant 168), 0.5 part of pentaerythritol stearin Ester made of long carbon fiber reinforced PPS resin masterbatch;

[0045] 65 parts of PPS resin, PPS is cross-linked polyphenylene sulfide, the weight average molecular weight is greater than 3.0*10 5 , 35 parts of high thermal conductivity carbon black, 0.5 part of silane coupling agent KH590, 0.4 part of antioxidant (composed of 0.2 part of antioxidant 1098, 0.2 part of antioxidant 168), 0.5 part of pentaerythritol stearate, 0.5 part of oxidation Polyethylene wax, mixed evenly, extruded and granulated by a twin-screw extruder ...

Embodiment 3

[0050] Adopt pultrusion method to make 80 parts (parts by weight, the same below) PPS resin, PPS is cross-linked polyphenylene sulfide, and the weight average molecular weight is greater than 3.0*10 5 , 20 parts of continuous long carbon fiber (pitch-based carbon fiber filament), 0.5 part of silane coupling agent KH590, 0.3 part of antioxidant (composed of 0.15 part of antioxidant 1076, 0.15 part of antioxidant 168), 0.5 part of pentaerythritol stearin Ester made of long carbon fiber reinforced PPS resin masterbatch;

[0051] 80 parts of PPS resin, PPS is cross-linked polyphenylene sulfide, the weight average molecular weight is greater than 3.0*10 5 , 20 parts of high thermal conductivity carbon black, 0.5 part of silane coupling agent KH590, 0.3 part of antioxidant (composed of 0.15 part of antioxidant 1076, 0.15 part of antioxidant 168), 0.5 part of pentaerythritol stearate, 0.3 part of oxidation Polyethylene wax, mixed evenly, extruded and granulated by a twin-screw extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com