150DEG C irradiation crosslinking low-smoke halogen-free flame retardant polyolefin material for locomotive wires and its preparation

A polyolefin and polyolefin resin technology, applied in the field of polymer materials for wires and cables, can solve the problems of high mechanical properties, high temperature resistance, no industrial production, unfavorable promotion and application, etc., and achieves good oil resistance and temperature resistance. High, low smoke effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

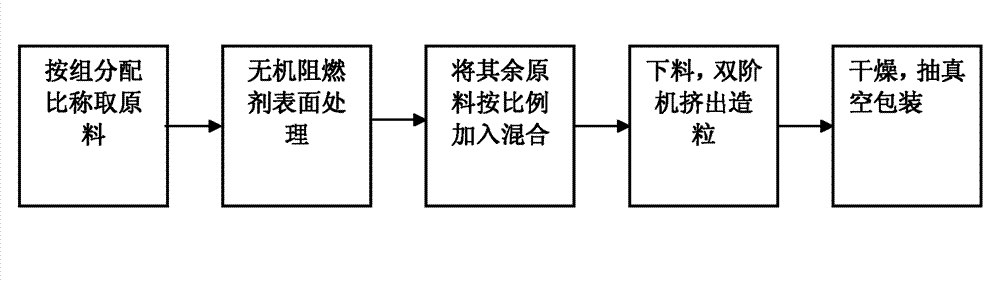

Method used

Image

Examples

Embodiment 1

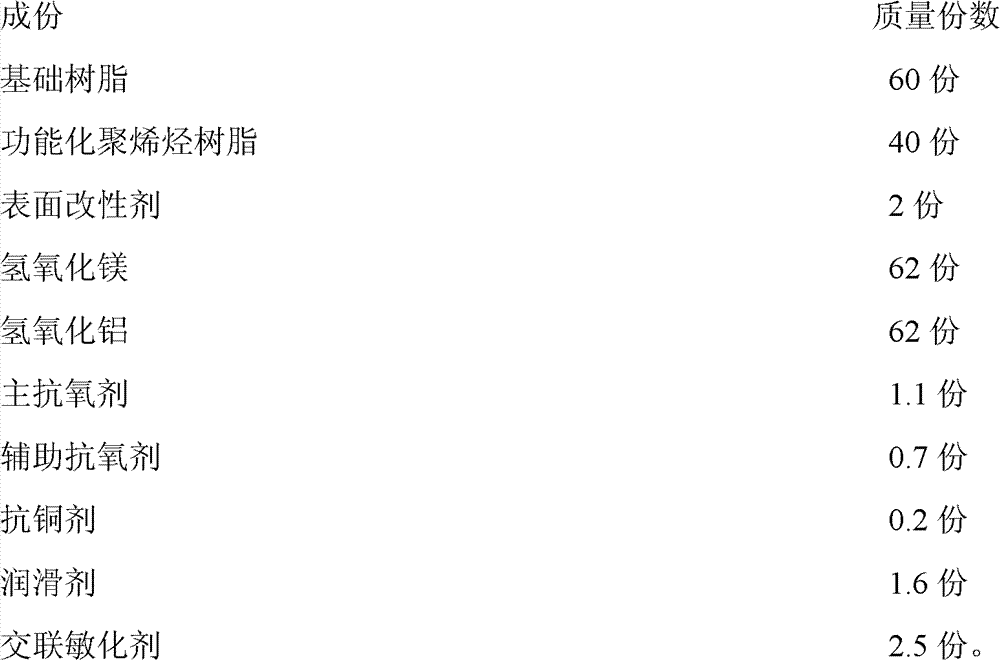

[0041] Irradiation cross-linked low-smoke halogen-free flame-retardant polyolefin material for 150℃ locomotive line, its raw material components and proportions are as follows:

[0042]

[0043] Wherein, based on the total weight of the base resin, the ethylene-vinyl acetate copolymer accounts for 50%, the ethylene-butyl acrylate copolymer accounts for 20%, and the ethylene-methacrylate copolymer accounts for 30%. The functional polyolefin resin is maleic anhydride grafted ethylene-vinyl acetate copolymer, maleic anhydride grafted polyolefin elastomer and maleic anhydride grafted low density polyethylene. The surface modifier is a silane coupling agent. The inorganic flame retardant is magnesium hydroxide and aluminum hydroxide surface-treated with a silane coupling agent (the silane coupling agent accounts for 1.6% of the mass fraction of the inorganic flame retardant). The main antioxidant is antioxidant 1010. The auxiliary antioxidants are antioxidant DLTP and antioxid...

Embodiment 2

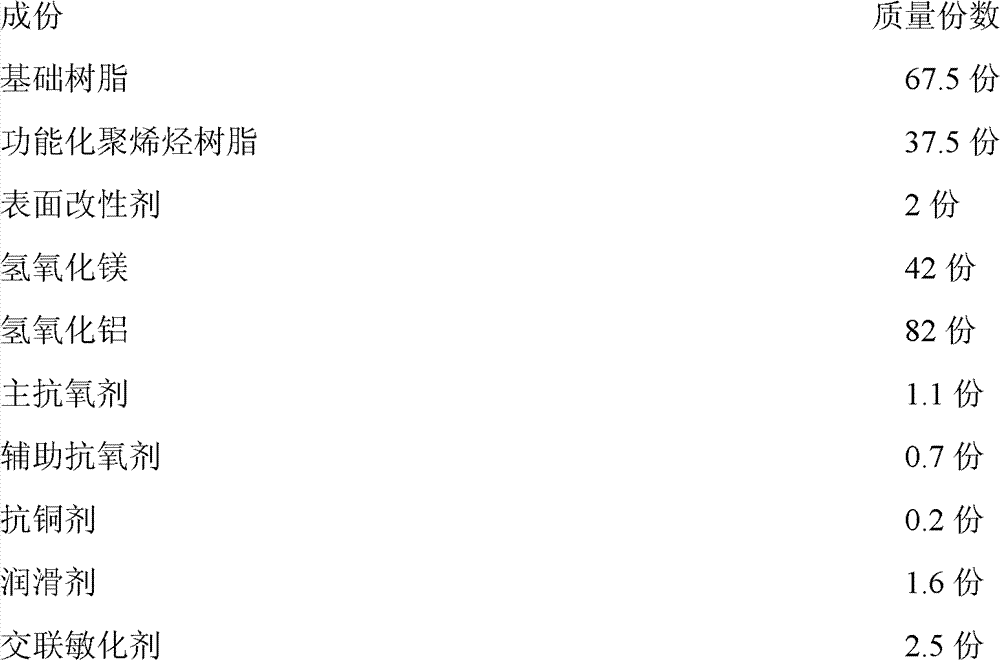

[0051] Irradiation cross-linked low-smoke halogen-free flame-retardant polyolefin material for 150℃ locomotive line, its raw material components and proportions are as follows:

[0052]

[0053] Among them, based on the total weight of the base resin, the ethylene-vinyl acetate copolymer accounts for 75%, the ethylene-butyl acrylate copolymer accounts for 10%, and the ethylene-methacrylate copolymer accounts for 15%. The functionalized polyolefin resin is maleic anhydride grafted ethylene-vinyl acetate copolymer and maleic anhydride grafted polyolefin elastomer. The surface modifier is a silane coupling agent. The inorganic flame retardant is magnesium hydroxide and aluminum hydroxide (silane coupling agent accounts for 2.2% of the mass fraction of the inorganic flame retardant) through silane coupling agent surface treatment. The main antioxidant is antioxidant 1010 . The auxiliary antioxidants are antioxidant DLTP and antioxidant 168. The anti-copper agent is MD1024. ...

Embodiment 3

[0057] Irradiation cross-linked low-smoke halogen-free flame-retardant polyolefin material for 150℃ locomotive line, its raw material components and proportions are as follows:

[0058]

[0059] Among them, based on the total weight of the base resin, the ethylene-vinyl acetate copolymer accounts for 60%, the ethylene-butyl acrylate copolymer accounts for 20%, and the ethylene-methacrylate copolymer accounts for 20%. The functionalized polyolefin resin is maleic anhydride grafted low density polyethylene. The surface modifier is a silane coupling agent. The inorganic flame retardant is magnesium hydroxide and aluminum hydroxide treated with a silane coupling agent (the silane coupling agent accounts for 2% of the mass fraction of the inorganic flame retardant). The main antioxidant is Antioxidant 300. The auxiliary antioxidants are antioxidant DLTP and antioxidant 168. The anti-copper agent is MD1024. Described lubricant is calcium stearate, polyethylene wax and silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com