Preparation method for oleanolic acid type saponin

A technology for oleanolic acid and saponin, which is applied in the fields of medicine and chemical industry, can solve the problems that the purity of the refined product needs to be further improved, the purification efficiency of the reversed-phase preparation process is affected, and the multiple isocratic elution process steps are complicated, so as to achieve automation and The effect of operability, ease of recovery and recycling, and simplified purification process burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The preparation of embodiment 1 Pulsatilla saponins PB4 and PB5

[0016] (1) Referring to the analysis results of Pulsatillae medicinal materials (see Shu Zhan, Research on the Chemical Composition of Chinese Medicine Pulsatilla 2, Master Thesis of Soochow University, 2012), select Pulsatilla saponin PB4 [chemical name: 3-O-α-L-rhamnopyranose] -(1→2)-α-L-arabinopyranose lupinin 28-O-α-L-rhamnopyranose-(1→4)-β-D-glucopyranose-(1→ 6)-β-D-glucopyranoside] and PB5 Pulsatilla rhizome medicinal material (place of origin: Anhui, batch PC20091101) as raw materials. Weigh 1 kg of Pulsatilla pulsatillae pieces, extract twice with 8L of 70% ethanol under reflux, each time for 2 hours, filter, combine the filtrate, concentrate under reduced pressure until no alcohol smell, add appropriate amount of water to adjust the liquid medicine so that each 1ml liquid medicine is equivalent to 1.0g crude drug, spare.

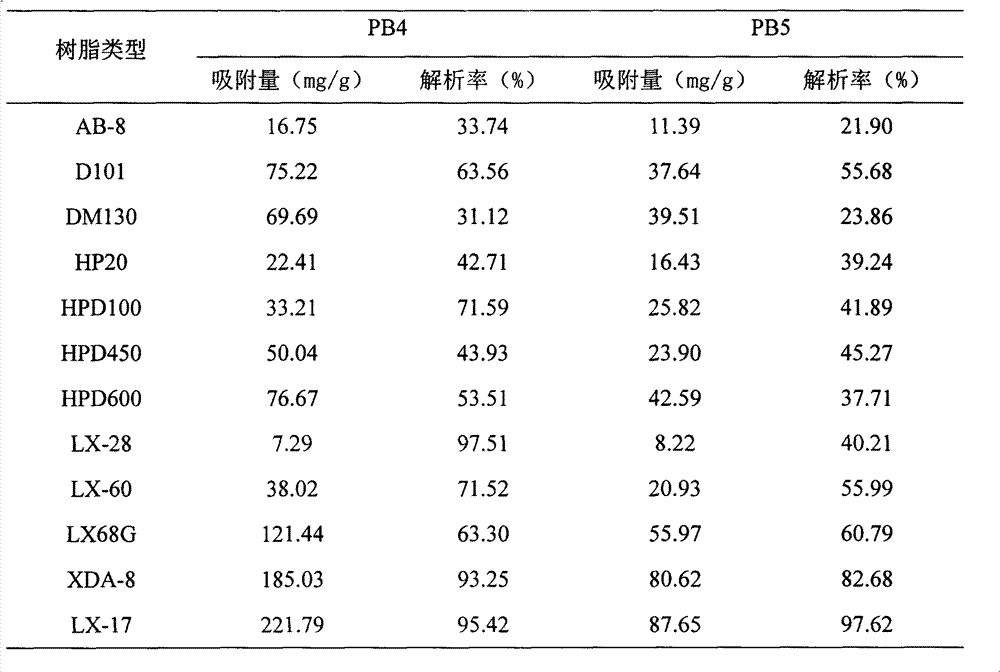

[0017] (2) Research on refining process of macroporous resin

[0018] R...

Embodiment 2

[0023]The preparation of embodiment 2 Pulsatilla saponins PB3 and PB7

[0024] PB3 chemical name: 3-O-α-L-rhamnopyranose-(1→2)[β-D-glucopyranose-(1→4)]-α-L-arabinopyranose hedera saponin ; PB3 and PB7 are the main anti-tumor active ingredients in plants such as Pulsatilla.

[0025] (1) Pulsatillae rhizomes rich in Pulsatilla saponins PB39 and PB7 precursor saponins (place of origin: Liaoning, batch PC20111001) were selected as raw materials. Weigh 30kg of Pulsatilla pulsatillae medicinal material, crush it into coarse grains, reflux extract with 420L 75% ethanol twice, each time for 2h, filter the extract, combine, concentrate under reduced pressure until there is no alcohol smell, add water to 100L, adjust and maintain pH9 with NaOH -11, boiled and hydrolyzed for 6 hours, adjusted to pH 7-9 with 1M HCl, diluted with water to 150L, and set aside.

[0026] (2) Macroporous resin refining process

[0027] Select D101 resin column (230cm×300mm i.d., column volume 150L / BV), af...

Embodiment 3

[0030] The preparation of embodiment 3 Patrinia saponin BJ26

[0031] BJ26 chemical name: 3-O-β-D-glucopyranose (1→4)-β-D-xylopyranose (1→3)-α-L-rhamnopyranose (1→2)- β-D-xylopyranose oleanolic acid) 28-O-β-D-glucopyranose (1→6)-β-D-glucopyranose, which is the main component of plants such as chrysanthemum patens and chervil (See Gao Liang, Research on the Chemical Constituents of Patrinia officinalis, Soochow University Master's Degree Thesis, 2011.).

[0032] (1) Extraction: 2.5kg of dried whole herb of Patonia chinensis (Origin: Yunnan, batch 120801), extracted twice by reflux with 10 times the amount of methanol, 1.5 hours each time, combined the extracts, filtered, concentrated and recovered under reduced pressure Methanol, add appropriate amount of water to dilute to 12.5L, set aside.

[0033] (2) Refining: select AB-8 resin column (100cm×10cm i.d., column volume 2.0L / BV), after pretreatment, take the extract from (1) and put it on the column, then use 6BV of water, 3B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com