Method for preparing high-purity quartz sands by using natural vein quartz ores

A technology of high-purity quartz sand and vein quartz is applied in the field of preparing high-purity quartz sand, which can solve the problems of unachievable quartz purity, different purification effects, and no application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

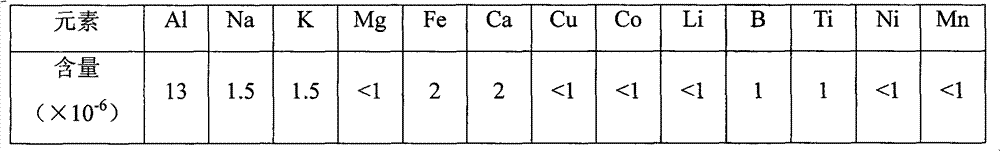

Embodiment 1

[0016] (1) Screening: Select good quality vein quartz raw ore, and remove the prominent impurities and foreign matter.

[0017] (2) Calcination-water quenching: heat the selected massive vein quartz in a muffle furnace to 900°C and keep it warm for 1 hour. After the calcination, the ore sample is taken out and directly put into water for quenching.

[0018] (3) Drying-crushing-grinding: the above-mentioned treated samples were placed in a vacuum drying oven to be fully dried. Use a jaw crusher to crush the dried quartz blocks into small pieces with a particle size of less than 2cm, and then use a sealed laboratory sample preparation grinder (GJ-2) to grind the pieces into quartz sand with a particle size of 2-100μm .

[0019] (4) Flotation: Weigh 200g of the quartz sand that step (3) obtains, and use appropriate amount of deionized water and 20%H 2 SO 4 The solution is prepared into a solution with pH=5.0, sodium oleate is used as feldspar activator, sodium hexametaphosphat...

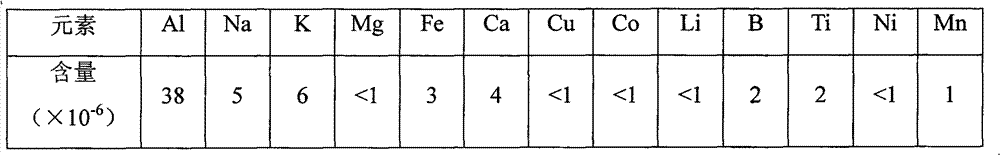

Embodiment 2

[0026] (1) Screening: Select good quality vein quartz raw ore, and remove the prominent impurities and foreign matter.

[0027] (2) Calcination-water quenching: heat the selected massive vein quartz in a muffle furnace to 900°C and keep it warm for 1 hour. After the calcination, the ore sample is taken out and directly put into water for quenching.

[0028] (3) Drying-crushing-grinding: the above-mentioned treated samples were placed in a vacuum drying oven to be fully dried. Use a jaw crusher to crush the dried vein quartz block into small pieces with a particle size of less than 2cm, and then use a sealed laboratory sample preparation grinder to grind the pieces into quartz sand with a particle size of 2-100 μm.

[0029] (4) Flotation: Weigh 200g of the quartz sand that step (3) obtains, and use appropriate amount of deionized water and 20%H 2 SO 4 The solution is prepared into a solution of pH=5.0, with sodium oleate as the feldspar activator, sodium hexametaphosphate as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com