Preparation method of bentonite for slurry

A technology of bentonite and mud, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low recovery rate of sodium-modified semi-finished products, increased process production complexity, and poor industrial operability, etc. , to achieve the effects of low preparation cost, improved macroscopic properties, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

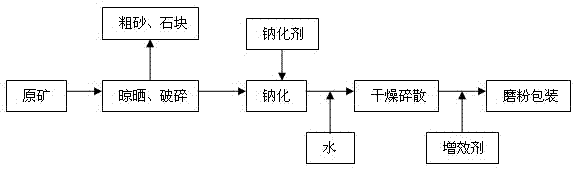

[0023] See figure 1 A preparation method of bentonite for mud, comprising the following steps:

[0024] (1) Drying and breaking. The calcium-based bentonite raw material is air-dried to a moisture content of ≤22%, coarse sand and stones are removed, and transported to a hammer crusher for crushing to obtain a mineral material with a particle size of ≤25mm.

[0025] (2) Sodium modification. The mineral material is transported to the roller compactor, and the roller compactor adopts a planetary roller mill or a double-screw extruder. Add sodiumizing agent and mix for 4 to 6 minutes. The sodiumizing agent is sodium carbonate or sodium fluoride. The amount added is 2.0% to 5.0% of the mass of the ore. Sodium ions are provided in the aqueous solution, so that the mineral material and the sodiumizing agent fully undergo a sodiumizing reaction, the water content is controlled at 22% to 25%, and the sodiumizing material is obtained by rolling for 15 to 30 minutes.

[0026] (3) Dri...

Embodiment 1

[0029] A preparation method of bentonite for mud, comprising the following steps:

[0030] (1) Drying and breaking. The calcium-based bentonite raw ore is air-dried to a moisture content of ≤22%, coarse sand and stones are removed, and transported to a hammer crusher for crushing to obtain mineral materials with a crushed particle size of ≤25mm.

[0031] (2) Sodium modification. Transport the mineral material to the planetary wheel mill, first add 2.0% of the mineral material mass of sodium carbonate and mix for 4 minutes, then add water, mix and roll to carry out sodium modification, control the water content at 22%, and roll for 15 minutes to obtain sodium material.

[0032] (3) Dried and broken. Transport the sodiumized material to a powerful drying pulverizer, crush and disperse it while drying, and control the moisture content to ≤12% to obtain semi-finished products.

[0033] (4) Synergistic milling. Add 1.0% sodium hydroxide and 0.5% polyacrylamide to the semi-fini...

Embodiment 2

[0035]A preparation method of bentonite for mud, comprising the following steps:

[0036] (1) Drying and breaking. The calcium-based bentonite raw ore is air-dried to a moisture content of ≤22%, coarse sand and stones are removed, and transported to a hammer crusher for crushing to obtain mineral materials with a crushed particle size of ≤25mm.

[0037] (2) Sodium modification. Transport the mineral material to the planetary wheel mill, first add 4.0% of the mineral material quality sodium carbonate and mix for 5 minutes, then add water, mix and roll for sodium modification, control the water content at 23%, and roll for 20 minutes to get sodium material.

[0038] (3) Dried and broken. Transport the sodiumized material to a powerful drying pulverizer, crush and disperse it while drying, and control the moisture content to ≤12% to obtain semi-finished products.

[0039] (4) Synergistic milling. Add 1.2% sodium hydroxide and 1.0% polyacrylamide to the semi-finished product,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com