Method for preparing heavy-viscous organophilic bentonite

A bentonite and high-viscosity technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as unstable quality, limited application fields, and low viscosity, so as to improve drying efficiency and avoid product quality. good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

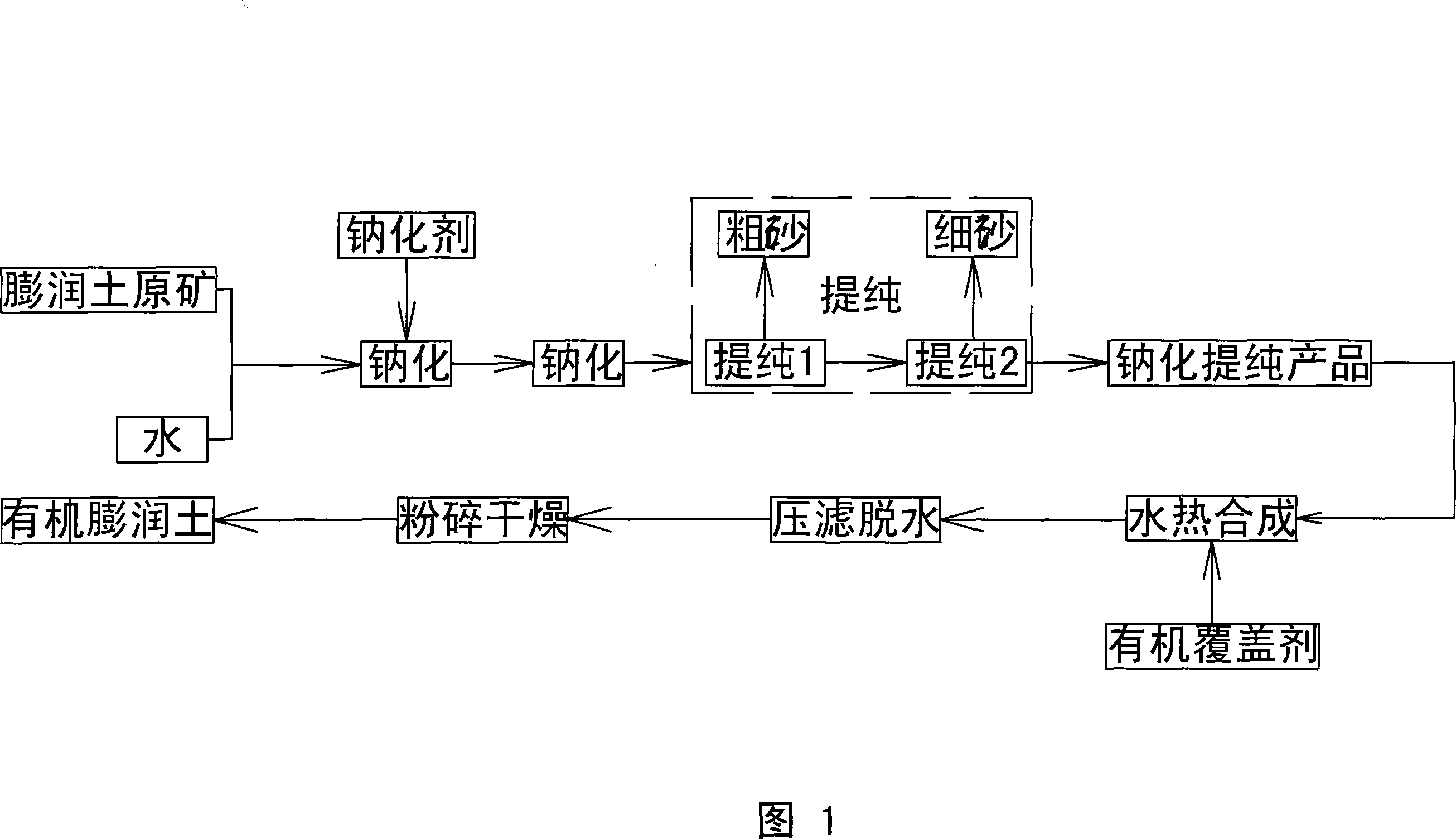

[0030] Embodiment one: a kind of preparation method of high-viscosity organobentonite, as shown in accompanying drawing 1, is made up of following steps successively:

[0031] (1) Sodiumization of bentonite raw ore: Add bentonite raw ore, water and sodiumizing agent into a ф1000×1000 sodiumization tank with a stirrer and mix, and stir at a stirring speed of 300r / min, and keep the sodiumization reaction for 60min Wherein, the mass ratio of water and bentonite raw ore is 13:1, and the mass ratio of sodiumizing agent and bentonite raw ore is 4%; sodium carbonate is selected as the modifying agent.

[0032] (2) Purification: ф50 hydrocyclone and WLB-350 horizontal screw centrifuge are connected in series; the sodiumized material enters ф50 hydrocyclone from the feed port of ф50 hydrocyclone, and passes through ф50 hydrocyclone in turn flow device and WLB-350 decanter centrifuge. The diameter of the overflow port of the ф50 hydrocyclone is 10mm, the diameter of the bottom flow por...

Embodiment 2

[0036] Embodiment two: a kind of preparation method of high-viscosity organobentonite, as shown in accompanying drawing 1, is made up of following steps successively:

[0037] (1) Sodiumization of bentonite raw ore: Add bentonite raw ore, water and sodiumizing agent into a ф1000×1000 sodiumization tank with a stirrer and mix, and stir at a stirring speed of 200r / min, and keep the sodiumization reaction for 40min The sodiumized material is obtained; wherein, the mass ratio of water to bentonite raw ore is 20:1, and the mass ratio of sodiumizing agent to bentonite raw ore is 8%; the sodiumizing modifying agent is a mixture of sodium carbonate and sodium chloride.

[0038] (2) Purification: ф50 hydrocyclone and WLB-350 horizontal screw centrifuge are connected in series; sodiumized material enters ф50 hydrocyclone from the feed port of ф50 hydrocyclone, and passes through ф50 hydrocyclone in turn And WLB-350 horizontal centrifuge. The diameter of the overflow port of the ф50 hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com