Hydraulic-driven self-cleaning filter provided with brushes

A self-cleaning filter, hydraulic drive technology, applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve the problems of low reliability and complex structure of cleaning devices, and achieve high reliability, easy installation and disassembly Simple and convenient, keep clean and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

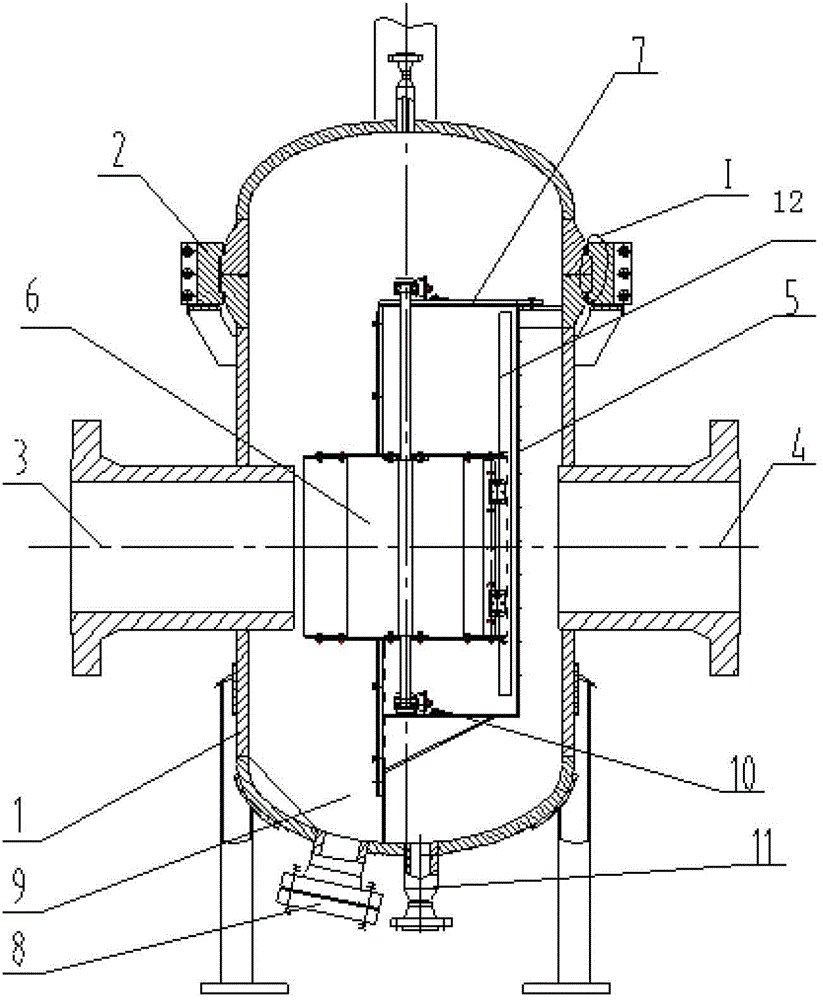

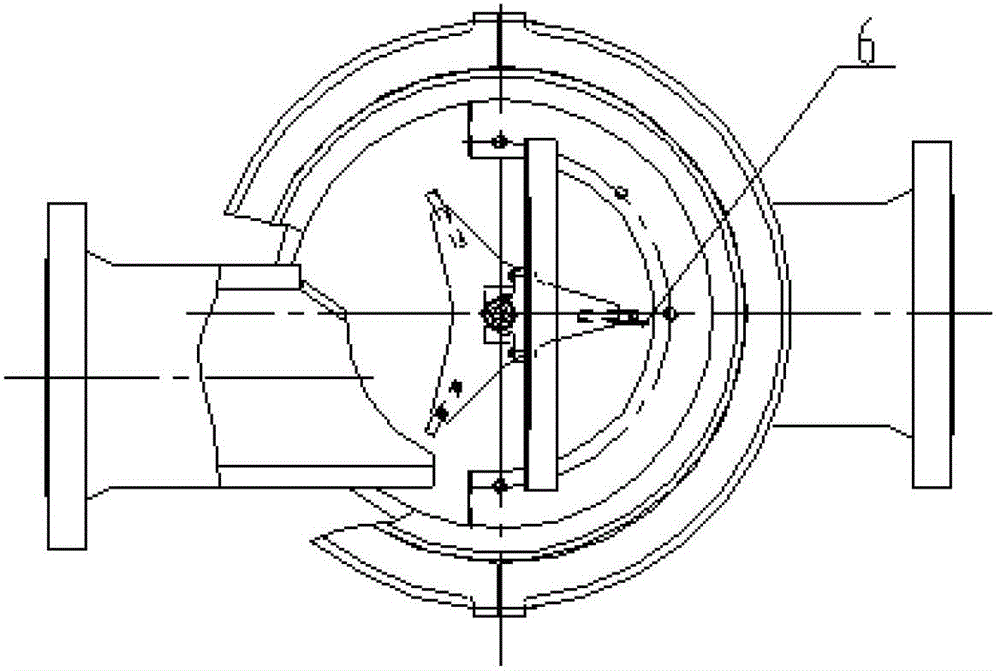

[0025] Based on the working principle of the water turbine, the present invention converts water energy into mechanical energy, and uses the energy of the liquid itself to drive the rotary cleaning device to perform 360° cycle rotation by rationally arranging the impeller, liquid outlet diameter and outlet inclination, and to clean the filter screen continuously. Make the filter residue gather in the conical slag collection chamber, and remove the filter residue through the slag discharge port.

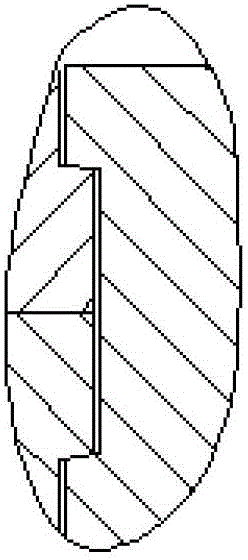

[0026] The brush-type hydraulically driven self-cleaning filter includes a filter housing 1, a liquid inlet 3 and a liquid outlet 4 installed on both sides of the filter housing, a filter cleaning device and a filter 5 arranged in front of the liquid outlet 4, and the filter The cleaning device includes an impeller and cleaning parts. The impeller includes a special-shaped wheel body and blades 6 installed on the wheel body. The number of blades can be set according to needs. The water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com