Nickel hydroxide nanosheet thin-film material as well as preparation method and application thereof

A technology of nickel hydroxide and thin film materials, which is applied in the direction of nickel oxide/nickel hydroxide, capacitors, electrical components, etc., and can solve the problems of difficulty in controlling the size and distribution of particle size, residual impurities on the surface, and poor crystallinity of products, etc. problem, to achieve the effect of large capacitance, simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a. Take the foam nickel sheet, put it into hydrochloric acid for ultrasonic washing, then transfer it to deionized water and ethanol, and ultrasonically wash it respectively;

[0028] b. prepare a solution with a nickel nitrate hexahydrate concentration of 0.125 mol / L and a hexamethylenetetramine concentration of 0.25 mol / L, and fully stir to obtain a homogeneous and stable solution;

[0029] c. Place the nickel foam sheet obtained in step a obliquely into a 40 ml autoclave with PTFE lining, and then transfer the solution in step b to the reaction kettle for 10 hours at 100°C with hydrothermal treatment. After the reaction is completed Cool to room temperature with cooling water, the cooling time is less than 15 minutes;

[0030] d. take out the nickel sheet in the reactor, rinse with water and ethanol, and finally ultrasonically clean in water and ethanol respectively;

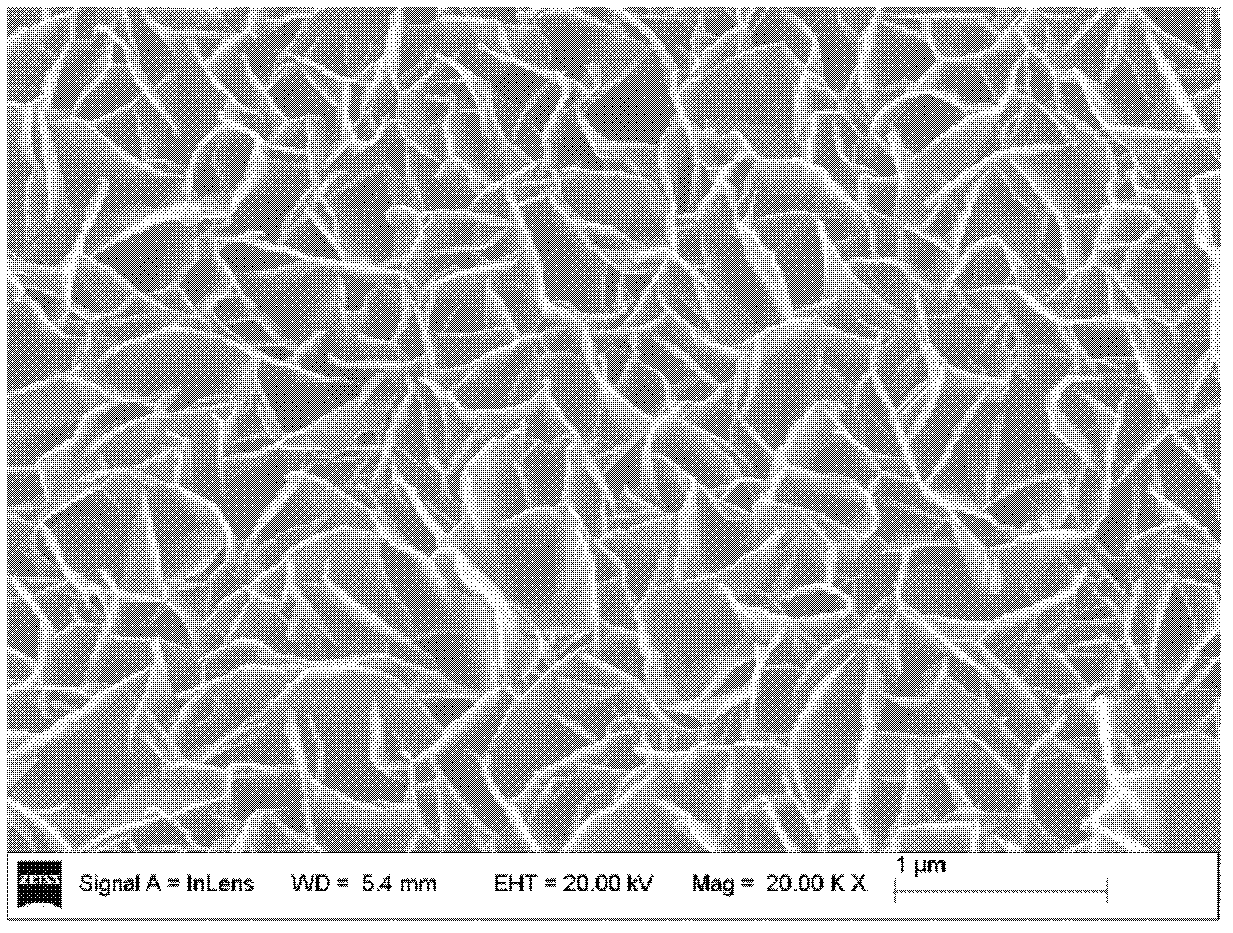

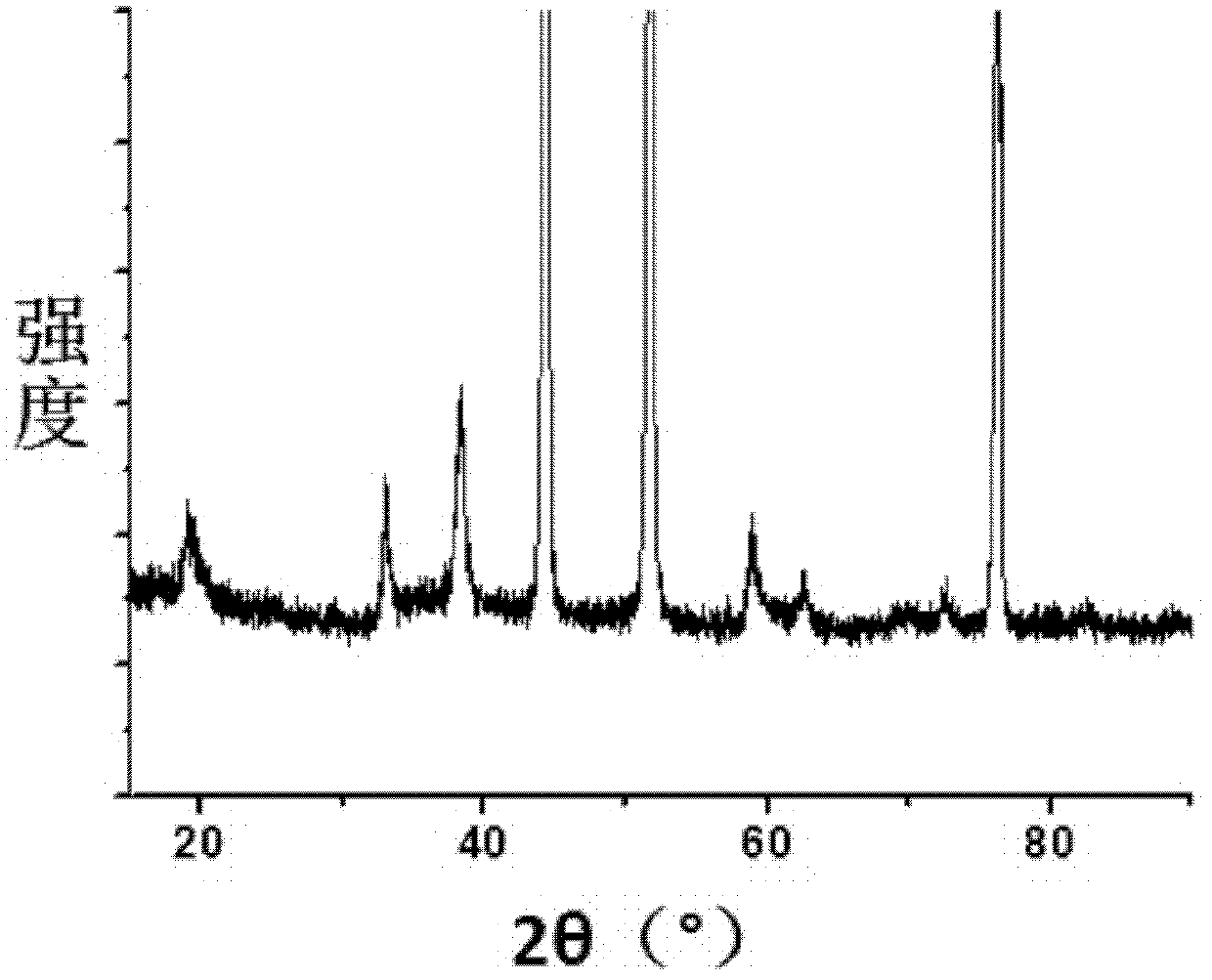

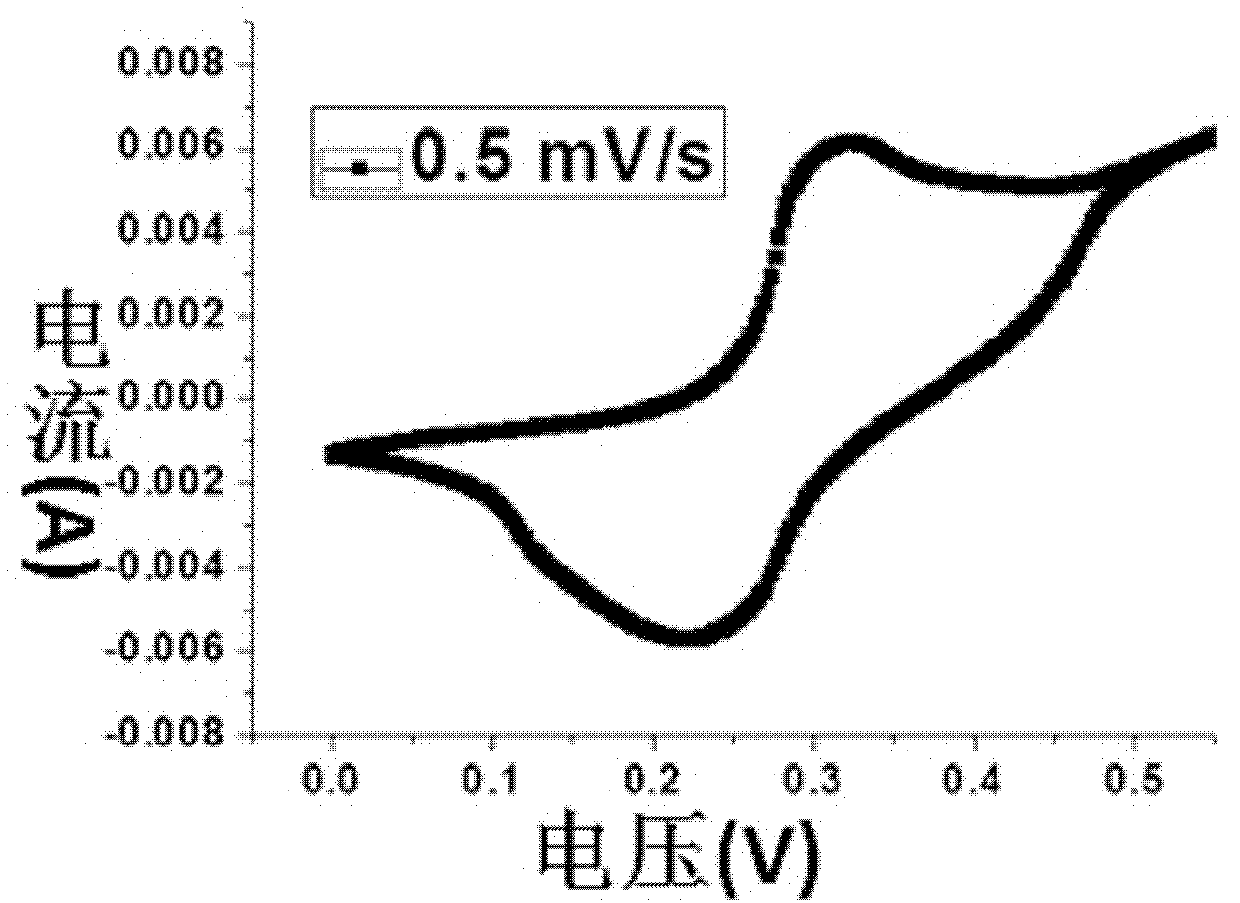

[0031] e. Put the product obtained in step d into a 100°C oven for 6 hours to obtain a nickel hydr...

Embodiment 2

[0034] a. Take the foam nickel sheet, put it into hydrochloric acid for ultrasonic washing, then transfer it to deionized water and ethanol, and ultrasonically wash it respectively;

[0035] b. Prepare a solution with a nickel nitrate hexahydrate concentration of 0.05 mol / L and a hexamethylenetetramine concentration of 0.05 mol / L, and fully stir to obtain a homogeneous and stable solution;

[0036] c. Place the nickel foam sheet obtained in step a obliquely into a 40 ml autoclave with PTFE lining, and then transfer the solution in step b to the reaction kettle for 48h at 140°C with hydrothermal treatment. After the reaction is completed Cool to room temperature with cooling water, the cooling time is less than 15 minutes;

[0037] d. take out the nickel sheet in the reactor, rinse with water and ethanol, and finally ultrasonically clean in water and ethanol respectively;

[0038] e. Put the product obtained in step d into a 100°C oven for 6 hours to obtain a nickel hydroxide ...

Embodiment 3

[0041] a. Take the foam nickel sheet, put it into hydrochloric acid for ultrasonic washing, then transfer it to deionized water and ethanol, and ultrasonically wash it respectively;

[0042] b. Prepare a solution with a nickel nitrate hexahydrate concentration of 0.25 mol / L and a hexamethylenetetramine concentration of 0.5 mol / L, and fully stir to obtain a homogeneous and stable solution;

[0043] c. Place the nickel foam sheet obtained in step a obliquely into a 40 ml autoclave with PTFE lining, and then transfer the solution in step b to the reaction kettle for 6 hours at 70°C with hydrothermal treatment. After the reaction is completed Cool to room temperature with cooling water, the cooling time is less than 15 minutes;

[0044] d. take out the nickel sheet in the reactor, rinse with water and ethanol, and finally ultrasonically clean in water and ethanol respectively;

[0045]e. Put the product obtained in step d into a 100°C oven for 6 hours to obtain a nickel hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com