Coal chemical industrial wastewater treating and recycling method combined with coal dressing process

A technology for coal chemical wastewater and biochemical treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost and non-zero discharge of wastewater, and achieve flexible methods, Taking into account the effects of treatment, economic treatment and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

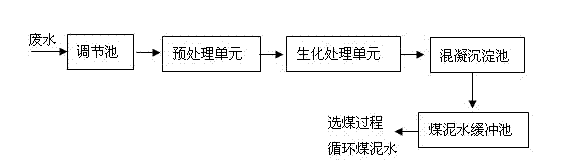

[0026] Example 1: figure 1 For the coal chemical industry wastewater treatment and utilization method of the present invention, the coal chemical industry wastewater is treated and utilized in cooperation with pretreatment, biochemical treatment and coal preparation process, and the wastewater treatment method comprises the following steps:

[0027] ① Pass the coal chemical wastewater in the wastewater regulating tank into the pretreatment unit for pretreatment;

[0028] ② Passing the pretreated waste water into the biochemical unit for biochemical treatment;

[0029] ③ Passing the biochemically treated wastewater into a coagulation sedimentation tank for coagulation and sedimentation treatment;

[0030] Wastewater utilization methods are:

[0031] ④ Pass the wastewater after the sedimentation treatment into the coal slime water buffer pool of the coal preparation plant, and use it as water for coal preparation; during the coal preparation process, refractory organic matter ...

Embodiment 2

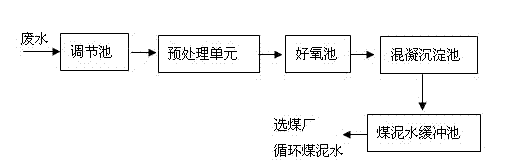

[0036] Example 2: figure 2 A specific embodiment of the coal chemical wastewater treatment and utilization method combined with the coal preparation process of the present invention is provided, including the following steps:

[0037] ①The coal chemical industry wastewater in the regulating tank is passed into the pretreatment unit, which regulates the homogeneity and quantity of the wastewater, and the pretreatment unit reduces pollutants by means of oil separation, air flotation, precipitation and hydrolysis acidification content and improve the biodegradability of wastewater.

[0038] ② Pass the pretreated waste water into the aerobic pool. The aerobic pool can be one level or multi-level. The aerobic process can be activated sludge or biofilm process. In this embodiment, the aerobic pool Biological aerated filter and biological aerated fluidized bed technology are adopted in sequence.

[0039] ③ Passing the biochemically treated wastewater into a coagulation sedimentati...

Embodiment 3

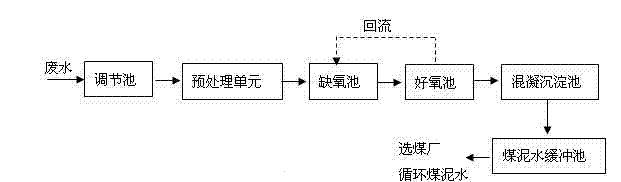

[0042] Embodiment 3: The biochemical treatment can pass through the anoxic pool and the aerobic pool in turn. image 3 For the coal chemical industry wastewater treatment and utilization method process combined with the coal preparation process, the specific steps are as follows:

[0043] ① Pass the coal chemical industry wastewater in the regulating tank into the pretreatment unit. This embodiment adopts the pretreatment method of precipitation and hydrolysis acidification. After the wastewater passes through, the pollutant content in it is reduced and the biodegradability of the wastewater is improved.

[0044] ② Pass the pretreated wastewater into the biochemical unit for biochemical treatment. In this embodiment, the biochemical unit includes an anoxic pool and an aerobic pool. The anoxic pool selects anoxic biological filter, and the aerobic pool selects exposure Gas biofilter. After pretreatment, the wastewater passes through the anoxic pool and the aerobic pool in turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com