New doubling drum and its manufacturing process

A manufacturing process and groove drum technology, applied in the field of new yarn doubling groove drum and its manufacturing process, can solve the problems of vibration routing, easy peeling, unpleasant, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

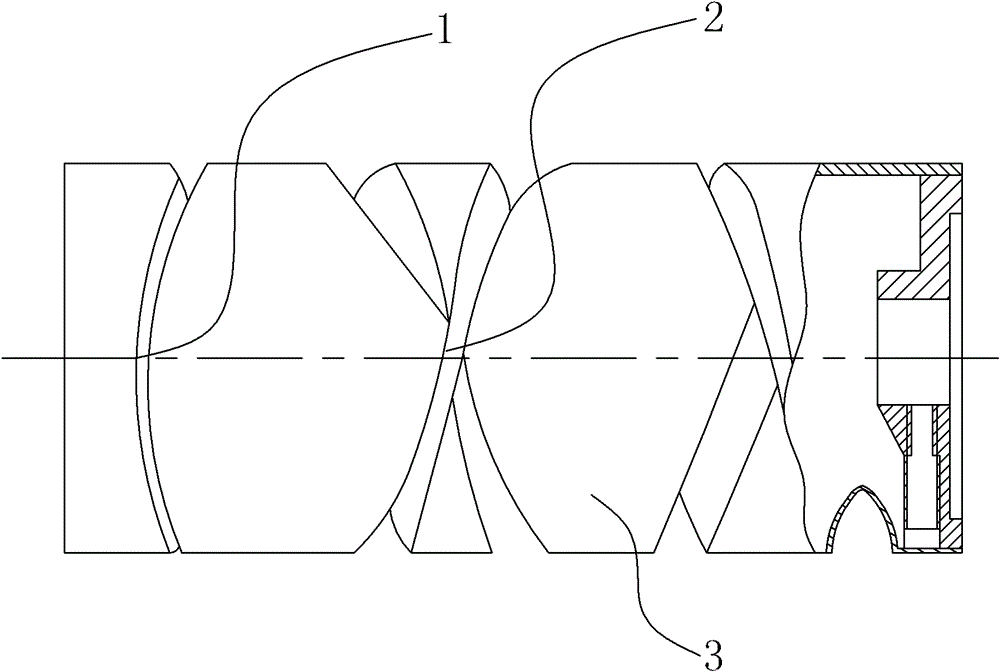

[0014] Such as figure 1 As shown, a new yarn doubling groove drum includes a groove drum body 3, on which two sets of parallel grooves, two sets of jumping slots, two sets of inclined surfaces of connecting grooves, two sets of corners 1, and one front and back of the cylinder body are provided. The inflection point 2 is characterized in that the two groups of corners 1 are naturally and smoothly transitioned to the top of the groove along the length direction, the top width of the corners 1 is 1.5 mm, the inflection point 2 is a transitional arc with a radius of 3.5 mm, and the inner cavity of the tank body is coated with After the glue is cured, an anti-cracking glue layer is formed.

[0015] A new type of yarn doubling tube manufacturing process, including batching smelting in sequence, casting mold rods, cutting the mold rods, extruding th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com