MnFePSi-based room-temperature magnetic refrigeration material and preparation method thereof

A magnetic refrigeration material and room temperature technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of small thermal hysteresis and magnetic hysteresis, achieve small magnetic hysteresis and thermal hysteresis, increase magnetic entropy, and achieve Curie temperature Continuously adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

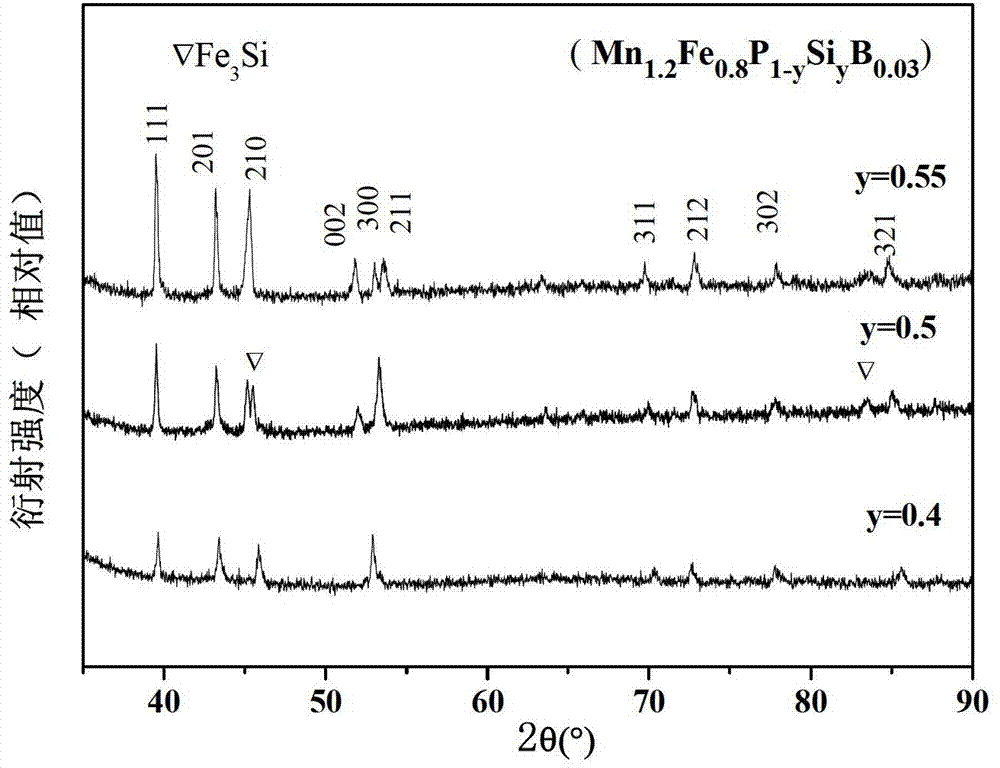

Embodiment 1

[0036] Step 1: Press Mn, Fe, P, Si and B into Mn 1.2 Fe 0.8 P 1-y Si y B 0.03 (y=0.4,0.5,0.55) (atomic ratio) ratio batching. The total weight of the sample is 10g, and when y=0.4, Mn, Fe, P, Si, and B are 4.684g, 3.174g, 1.321g, 0.798g, and 0.023g, respectively. When y=0.5, Mn, Fe, P, Si, and B are 4.694g, 3.181g, 1.103g, 0.999g, and 0.023g, respectively. When y=0.55, Mn, Fe, P, Si, and B are 4.698g, 3.184g, 0.994g, 1.101g, and 0.023g, respectively.

[0037] Step 2: Put the powder raw material prepared in step 1 into a ball mill jar in a high-purity argon-protected glove box, and after sealing with a cover, the ball mill jar is protected by argon gas atmosphere. Under the ball milling speed of 350 r / min, the mixture in the tank was ground by gap ball milling, and the ball milling was done for 5 hours to obtain a powder larger than 300 mesh.

[0038] Step 3: Put the powder prepared in Step 2 into the grinding tool under the protection of argon, 8 Pa into a cylindrical ...

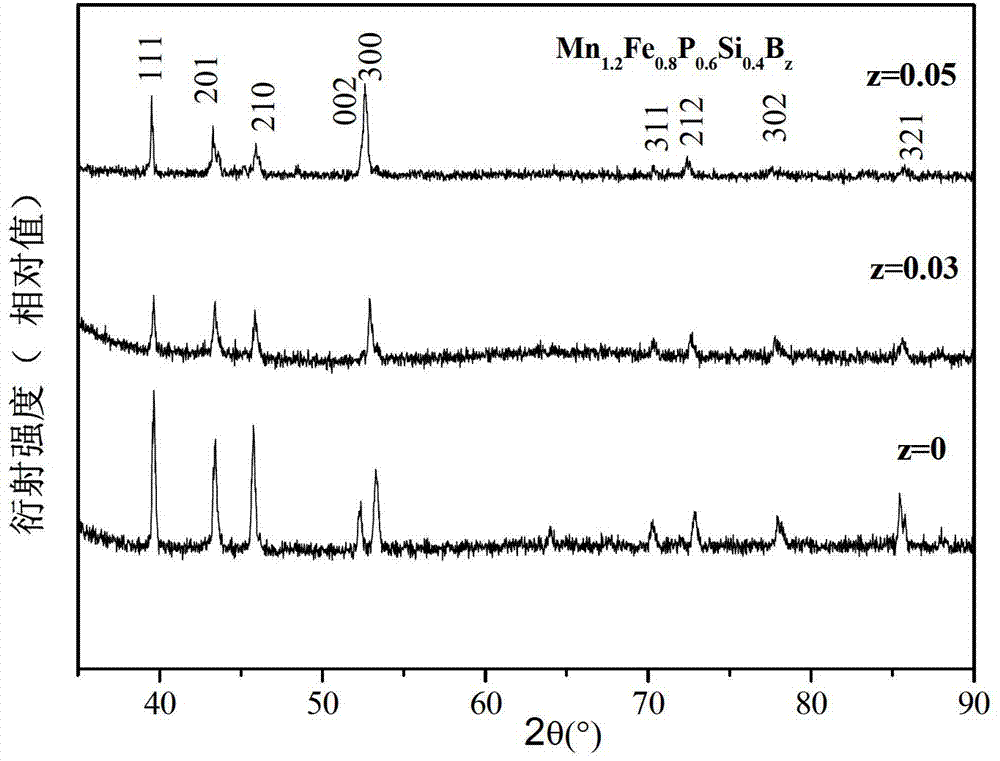

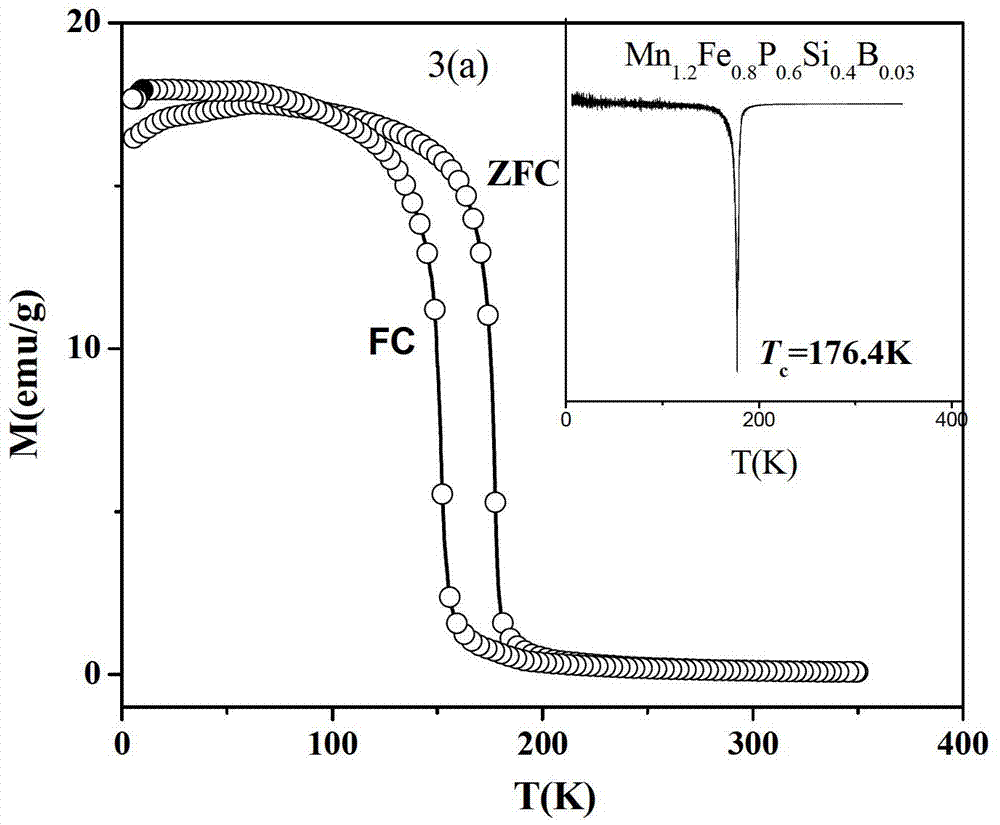

Embodiment 2

[0045] Step 1: Press Mn, Fe, P, Si and B into Mn 1.2 Fe 0.8 P 0.6 Si 0.4 B z (z=0,0.03,0.05) (atomic ratio) ratio batching. The total weight of the sample is 10g, and when z=0, Mn, Fe, P, and Si are 4.695g, 3.182g, 1.323g, and 0.800g, respectively. When z=0.03, Mn, Fe, P, Si, and B are 4.684g, 3.174g, 1.321g, 0.798g, and 0.023g, respectively. When z=0.05, Mn, Fe, P, Si, and B are 4.677g, 3.170g, 1.318g, 0.797g, and 0.038g, respectively.

[0046] Step 2: Put the powder raw material prepared in step 1 into a ball mill jar in a high-purity argon-protected glove box, and after sealing with a cover, the ball mill jar is protected by argon gas atmosphere. Under the ball milling speed of 350 r / min, the mixture in the tank was ground by gap ball milling, and the ball milling was done for 5 hours to obtain a powder larger than 300 mesh.

[0047] Step 3: Put the powder prepared in Step 2 into the grinding tool under the protection of argon, 8 Pa into a cylindrical sample. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com