Surface plasma ultra-diffraction photoetching method based on tip-insulator-metal structure

A surface plasmon, metal probe technology, applied in the field of plasma superdiffraction lithography, can solve the problems of asymmetric light spot, high background light intensity, background interference, etc., to avoid background interference field, good focal spot uniformity, Consistent spot size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation cases of the present invention will be introduced below with reference to the accompanying drawings, but the scope of protection of the present invention is not limited to the following embodiments, but should include all content in the claims.

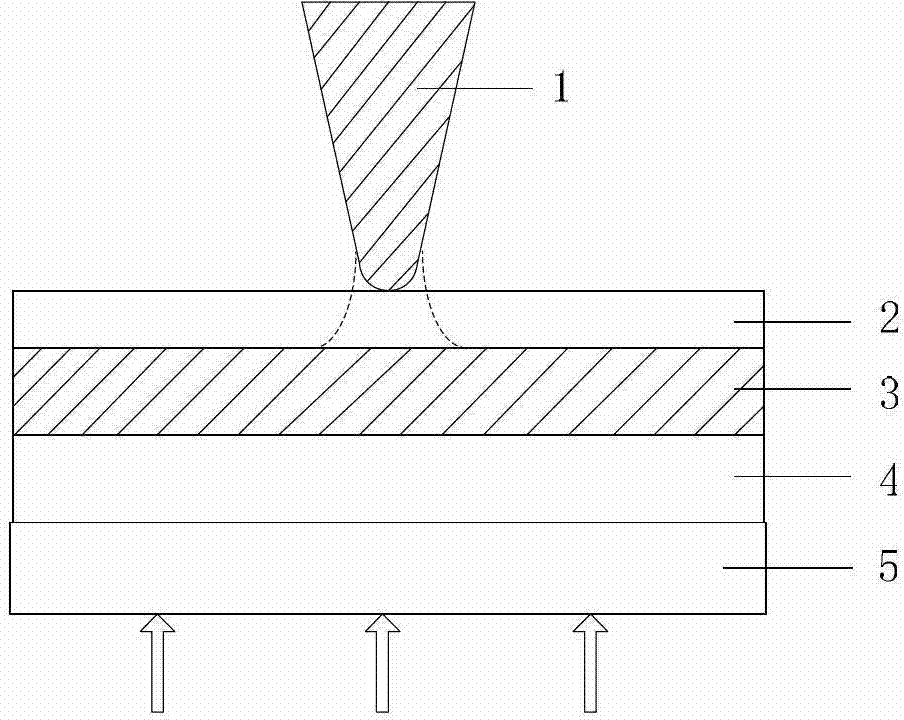

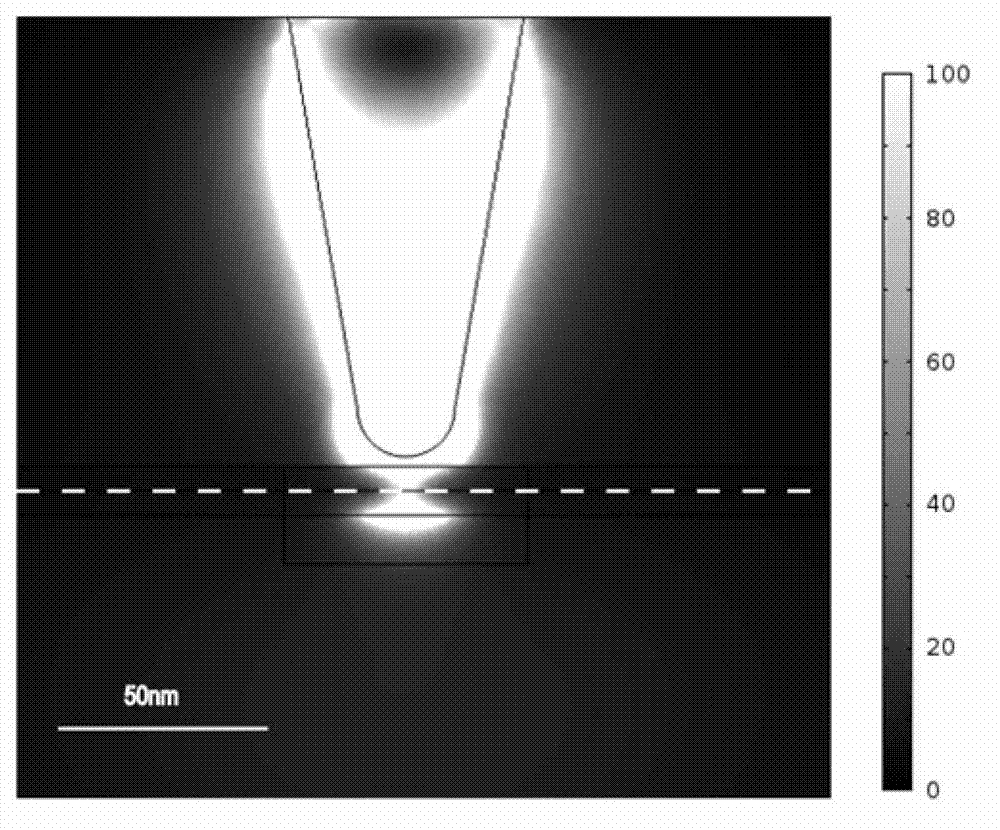

[0025] figure 1 It is a schematic diagram of the surface plasmon superdiffraction lithography method based on the metal-medium-probe (TIM) structure of the present invention, wherein the TIM structure is composed of a metal reflective layer 3 , a medium recording layer 2 and a metal probe 1 . The base can be made of transparent glass 5 , or transparent glass 5 plus dielectric material 4 . The incident light is normally incident on the TIM structure from the bottom surface of the substrate, and the localized surface plasmon is excited at the tip of the probe 1, and the localized surface plasmon is localized on the surface of the tip and decays exponentially along the longitudinal direction. Therefore, in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com