Film ablation sensor and manufacturing method thereof

A sensor and film technology, applied in the direction of material resistance, can solve the problems of complex production process of ablation sensors and low sensor reliability, and achieve the effects of improving consistency, improving processing efficiency and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

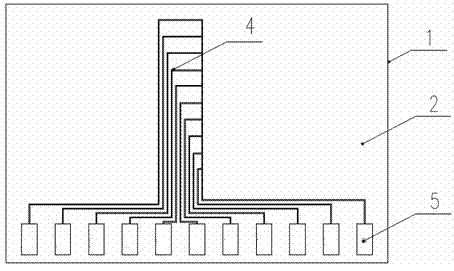

[0035] see Figure 1 to Figure 5 , the thin film ablation sensor 1 includes a substrate 2, a transition layer 3 disposed on the substrate 2, an ablation resistor 4 disposed on the transition layer 3; a protective film 6 is provided on the ablation resistor 4; The corrosion resistance 4 is a resistance sequence composed of more than two resistances; the resistance includes a lead wire welding panel 5; the lead welding panel 5 is connected to the adapter plate 13 through a lead 10; the base 2 is provided with a height Adjustment hole 9;

[0036] Wherein, the material of the base 2 is Al 2 o 3 , with a diameter of 50 mm to 150 mm and a thickness of 0.5 mm to 1 mm; the material of the transition layer 3 is Ta 2 o 5 , with a thickness of 0.05 μm to 0.1 μm; the material of the ablation resistor 4 is Au, and its thickness is 0.2 μm to 0.5 μm; the material of the protective film 6 is SiO 2 , the thickness is 0.1μm~0.2μm. The height adjustment hole 9 is a through hole of 1.6mm×10...

Embodiment 2

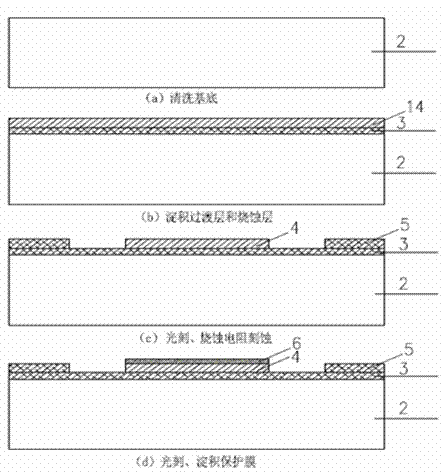

[0038] (1) For Al with a diameter of 50mm~150mm and a thickness of 0.5mm~1mm 2 o 3 The substrate 2 is cleaned to remove oil and impurities on the polished surface of the substrate;

[0039](2) Deposit Ta with a thickness of 0.05 μm to 0.1 μm by ion beam sputtering 2 o 5 The transition film 3 is used to enhance the bonding force between the Au thin film layer and the base layer 2;

[0040] (3) Ion beam sputtering deposits an Au thin film layer with a thickness of 0.2 μm to 0.5 μm, which is the ablation material layer 14 ;

[0041] (4) Make and ablate the photoresist mask layer in the shape of a resistor on the Au film by photolithography, and use iodine and potassium iodide etching solution to etch the Au film to remove the unnecessary Au film area to form an Au film ablation Resistor 4 and lead welding area 5;

[0042] (5) Make a photoresist mask layer by photolithography process to protect the lead welding area;

[0043] (6) Ion beam sputtering deposits SiO with a thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com