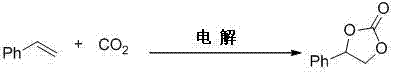

Method for preparing cyclic carbonate from olefin and carbon dioxide by electrochemical method

A technology of cyclic carbonate and raw material electrochemistry, applied in organic chemistry, electrolytic process, electrolytic components, etc., can solve the problems of large metal material consumption, troublesome separation and purification, and increased cost, and achieve low production cost and excellent reaction system Simple and effective, low material consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] With the graphite electrode as the anode and metal nickel as the cathode, add 20mL dimethyl sulfoxide (DMSO for short), 1mmol styrene, 30mmol chlorine in 100mL stainless steel single-chamber high-pressure electrolytic cell lined with polytetrafluoroethylene. Sodium chloride, magnetic stirrer, and carbon dioxide gas to 0.1MPa, sealed; in constant current mode, 0.06A direct current, electrolysis at room temperature for 3 hours, stop power supply; after electrolysis, slowly release unreacted Carbon dioxide gas, the electrolytic solution was distilled under reduced pressure, and then extracted three times with ether, and the target product styrene cyclic carbonate was obtained after the ether volatilized.

[0032] The structure of the resulting product is determined by IR, 1 H NMR, 13 Confirmed by C NMR and GC-MS. The isolated yield of styrene cyclic carbonate was 93%.

Embodiment 2

[0034] With the graphite electrode as the anode and the stainless steel as the cathode, add 20mL of N,N -Dimethylformamide (abbreviation: DMF), 1mmol styrene, 20mmol ammonium chloride, magnetic stirrer, and then introduce carbon dioxide gas to 0.1MPa, seal; in constant current mode, connect 0.06A DC, Electrolyze at room temperature for 3 hours, stop power supply; after electrolysis, slowly release unreacted carbon dioxide gas, distill the electrolyte under reduced pressure, and then extract with ether three times, the target product styrene cyclic carbonate is obtained after the ether volatilizes.

[0035] The structure of the resulting product is determined by IR, 1 H NMR, 13 Confirmed by C NMR and GC-MS. Styrene cyclic carbonate was isolated in 90% yield.

Embodiment 3

[0037]With the graphite electrode as the anode and the brass sheet (i.e. Cu-Sn alloy) as the cathode, add 20mL of DMF, 1mmol of styrene, and 20mmol of bromine to a 100mL stainless steel single-chamber high-pressure electrolytic cell lined with polytetrafluoroethylene. Potassium chloride, magnetic stirrer, and then carbon dioxide gas to 0.1MPa, sealed; in the constant current mode, connected to a 0.06A direct current, electrolyzed at room temperature for 3 hours, stop power; after the electrolysis, slowly let go The reacted carbon dioxide gas, the electrolytic solution was distilled under reduced pressure, and then extracted three times with ether, and the target product styrene cyclic carbonate was obtained after the ether volatilized.

[0038] The structure of the resulting product is determined by IR, 1 H NMR, 13 Confirmed by C NMR and GC-MS. The isolated yield of styrene cyclic carbonate was 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com