Polycarboxylate superplasticizer for effectively resisting adverse influence from clay and preparation method of polycarboxylate superplasticizer

A technology of polycarboxylate and water reducer, which is applied in the field of polycarboxylate water reducer and its preparation, can solve the problems of reducing PC water reduction and slump retention, and achieves the suppression of adverse effects of clay, mild conditions, and simple reaction steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Into the 5L reactor, add 0.5 mol methyl alkenyl polyoxyethylene polyoxypropylene ether (R 1 is methyl, m = 30, n = 15), 0.62 mol monomer N-isopropyl methacrylamide, 0.09 mol dodecanethiol and 1000 g deionized water, stirred to dissolve, and heated to 36 °C. 3.34 mol aqueous solution of monomeric acrylic acid, 0.20 mol ammonium persulfate aqueous solution and 0.05 mol sodium bisulfite aqueous solution were added dropwise, the drop was completed within 2.5 hours, and the temperature was kept for 4 hours. After the reaction, cool down to 30°C, add sodium hydroxide to neutralize to pH = 6.8, add water to adjust the solid content to 40%, and obtain a light yellow transparent liquid, which is a polycarboxylate superplasticizer that can effectively resist the adverse effects of clay , The number average molecular weight is 16000.

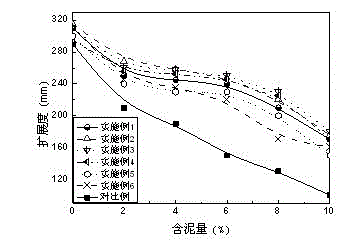

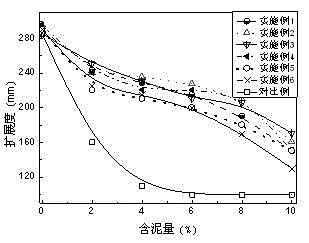

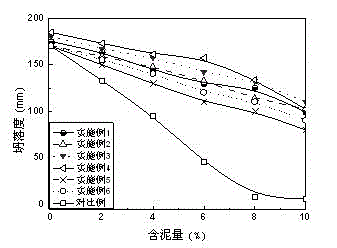

[0045]In the cement slurry test, when the mud content is 0, the initial expansion degree is 310mm, and the expansion degree is 290mm after 1 hour;...

Embodiment 2

[0048] Into the 5L reactor, add 0.5 mol monomer methyl alkenyl polyoxyethylene polyoxypropylene ether (R 1 is methyl, m = 20, n = 21), 0.62 mol monomer N-(methoxymethyl)-2-acrylamide, 0.04 mol mercaptopropionic acid and 1000 g deionized water, stirred to dissolve, and heated to 40°C. Add dropwise 2.69 mol monomeric acrylic acid aqueous solution, 0.13 mol sodium persulfate aqueous solution and 0.06 mol ascorbic acid aqueous solution, drop it within 3 hours, and keep warm for 3 hours. Cool down to 30°C after the reaction is over, and add potassium hydroxide to neutralize to pH=6.7, and add water to adjust the solid content to 40%, to obtain a light yellow transparent liquid, which is the polycarboxylic acid reducing agent that can effectively resist the adverse effects of clay. Aqua, the number average molecular weight is 12000.

[0049] In the cement slurry test, when the mud content is 0, the initial expansion degree is 315mm, and the expansion degree is 295mm after 1 hour; ...

Embodiment 3

[0052] Into the 5L reactor, add 0.5 mol monomer alkenyl polyoxyethylene polyoxypropylene ether (R 1 is H, m = 25, n = 24), 0.57 mol monomer N-2-(dimethylaminopropyl) methacrylamide, 0.07 mol mercaptoethanol and 1000 g deionized water, stirred to dissolve, and heated to 42°C. Add 2.2 mol monomeric methacrylic acid aqueous solution, 0.08 mol hydrogen peroxide aqueous solution and 0.05 mol ascorbic acid aqueous solution dropwise, drop it within 2.5 hours, and keep warm for 2 hours. Cool down to 30°C after the reaction is over, and add sodium hydroxide to neutralize to pH=6.5, and add water to adjust the solid content to 40%, to obtain a light yellow transparent liquid, which is the polycarboxylic acid reducing agent that can effectively resist the adverse effects of clay. Aqua, number average molecular weight is 10000.

[0053] In the cement slurry test, when the mud content is 0, the initial expansion degree is 310mm, and the expansion degree is 285mm after 1 hour; when the mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com