Barrier discharge plasma surface treatment system for large-breath medium

A dielectric barrier discharge and plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problems of short treatment time, weak treatment strength, no ozone absorption or catalytic decomposition ability, etc., to increase wetting performance and strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

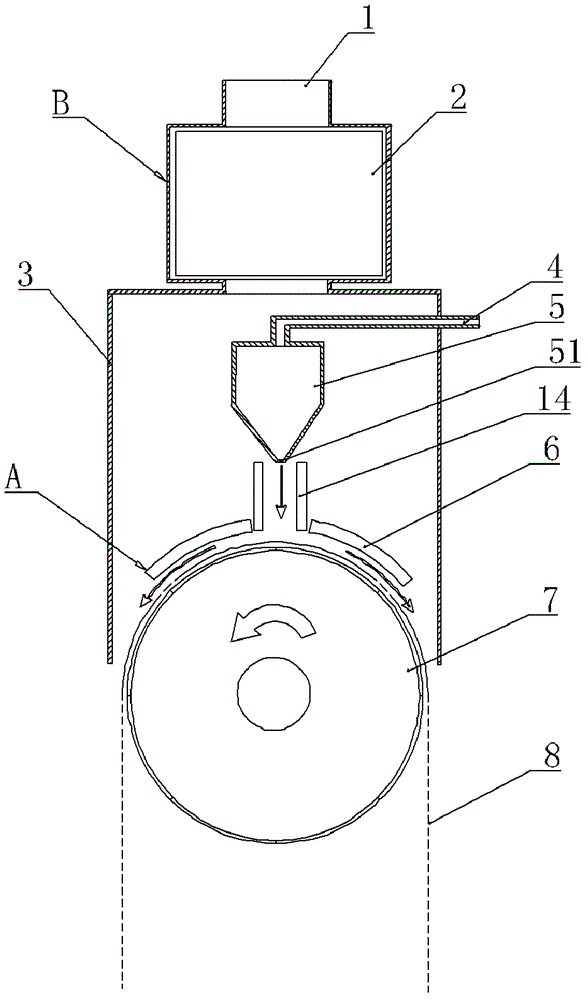

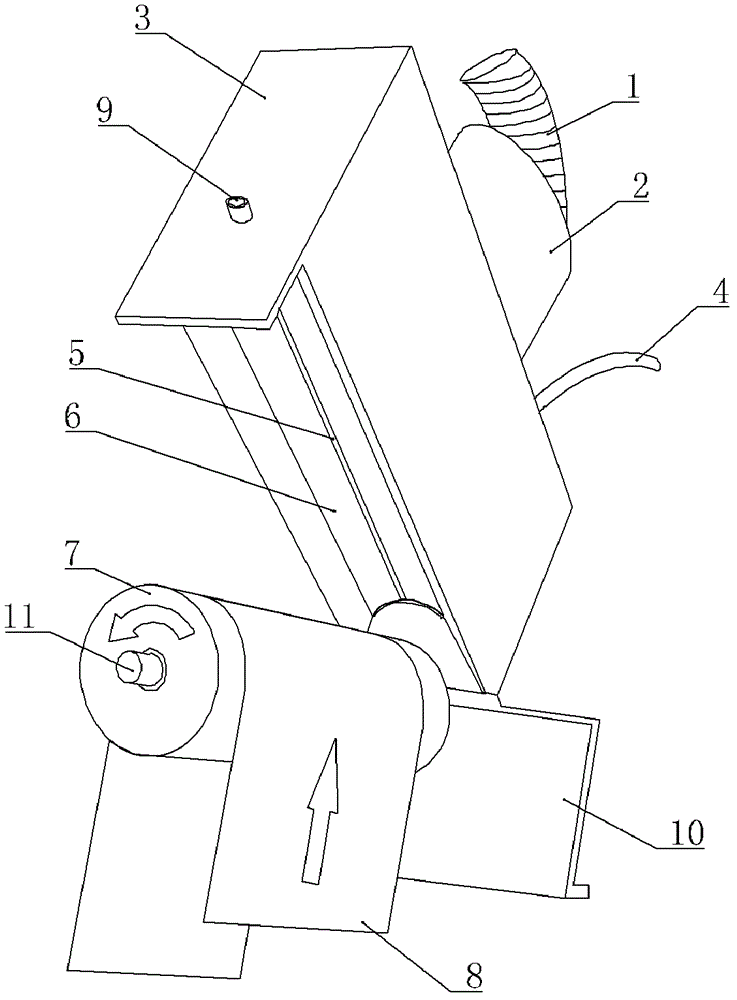

[0046] see Figure 1 to Figure 14 According to the present invention, a large-format dielectric barrier discharge plasma surface treatment system includes a dielectric barrier discharge plasma treatment component A, and an ozone absorption device B is arranged above the dielectric barrier discharge plasma treatment component A.

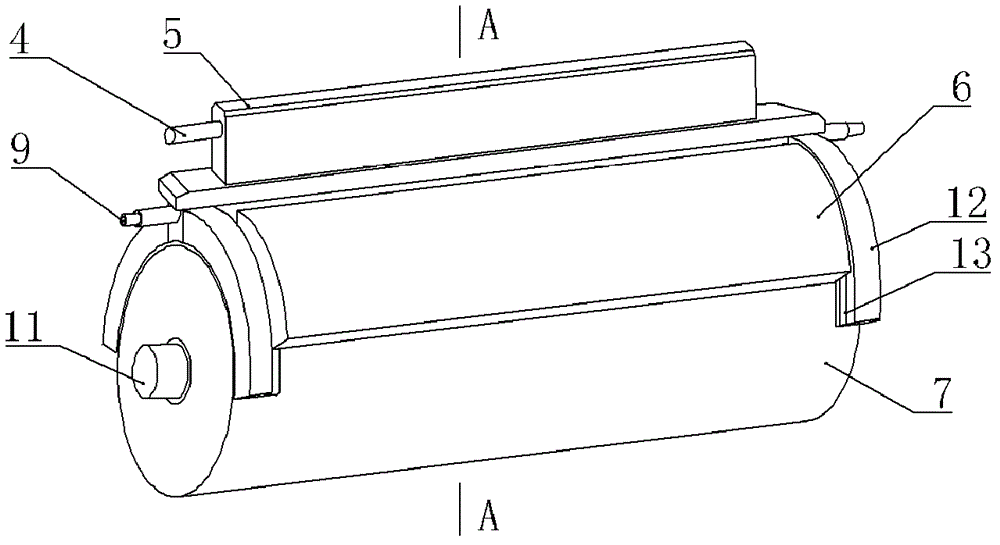

[0047] The dielectric barrier discharge plasma processing assembly A includes a grounding roller 7, an electrode plate 6 and a gas delivery device. The main shafts 11 at both ends of the grounding roller 7 are rotatably supported on the frame 10, and above the grounding roller 7, a For the electrode plate 6 whose arc surface is concentric with the grounding roller 7 and has an equal discharge distance with the outer peripheral surface of the grounding roller 7, a water cooling channel and a circulating water interface connected to both ends of the electrode plate 6 are provided in the electrode plate 6 9. A gas delivery device is installed between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com