Preparation method for spherical mesoporous lithium iron phosphate anode material

A technology of mesoporous lithium iron phosphate and cathode material, which is applied in battery electrodes, electrical components, circuits, etc., to achieve the effect of simple process flow and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

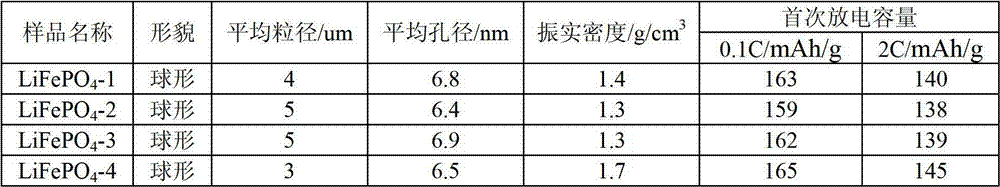

Embodiment 1

[0028]Weigh lithium carbonate, ferrous oxalate, triammonium phosphate, citric acid and cetyltrimethylammonium phosphate according to molar ratio Li:Fe:P:reducing agent:surfactant=1:0.9:0.9:0.01:0.01 , weigh CMK-3 according to the mass ratio Fe: ordered mesoporous carbon = 1:0.1, and mix it in deionized water to form a mixed solution with a Fe concentration of 3mol / L, and then put the mixed solution in N2 atmosphere, Reaction at 200°C for 30h, the resulting product was filtered and dried at 80°C for 24h, and the obtained spherical nano-lithium iron phosphate precursor was kept at 500°C for 16h in an N2 atmosphere to obtain a spherical mesoporous lithium iron phosphate cathode material. Denoted as LiFePO4-1.

Embodiment 2

[0030] Weigh lithium formate, ferrous acetate, ammonium dihydrogen phosphate, formaldehyde and cetyltriethylammonium phosphate according to molar ratio Li: Fe: P: reducing agent: surfactant = 1: 1.1: 1.1: 0.03: 0.03 , weigh C-MTS-9 according to the mass ratio Fe: ordered mesoporous carbon = 1:0.2, and mix it in deionized water to form a mixed solution with a Fe concentration of 0.5mol / L, and then put the mixed solution in Ar In the atmosphere, react at 350 ° C for 15 h, and the obtained product is filtered and dried at 200 ° C for 2 h. Lithium cathode material, denoted as LiFePO4-2.

Embodiment 3

[0032] Weigh lithium hydroxide, ferrous carbonate, diammonium hydrogen phosphate, ethylene glycol and cetyltrimethyl by molar ratio Li:Fe:P:reducing agent:surfactant=1:0.9:1.1:0.01:0.03 Ammonium bromide, weigh CMK-3 according to the mass ratio Fe:ordered mesoporous carbon=1:0.2, and mix it in deionized water to form a mixed solution with a Fe concentration of 0.5mol / L, and then put the mixed solution in In a He atmosphere, react at 200°C for 30h, and the obtained product is filtered and dried at 80°C for 24h. The obtained spherical mesoporous lithium iron phosphate precursor is in a He atmosphere, and after a constant temperature of 500°C for 16h, a spherical mesoporous phosphoric acid is obtained. Lithium iron cathode material, denoted as LiFePO4-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com