Forming and capacity grading method of lithium ion secondary battery

A secondary battery and lithium-ion technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve problems such as low efficiency, underclamping, immature process and gas-produced lithium, so as to avoid Or reduce the effect of lithium analysis and improve the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

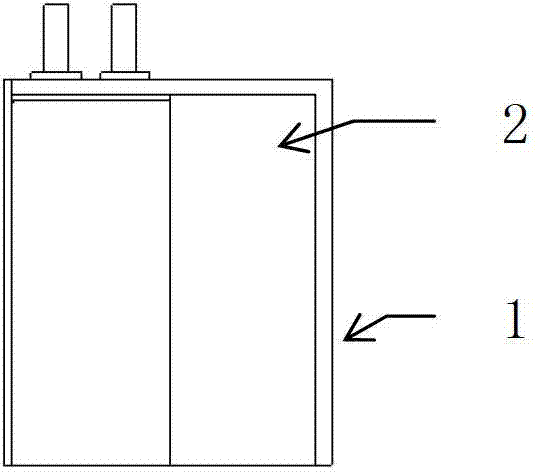

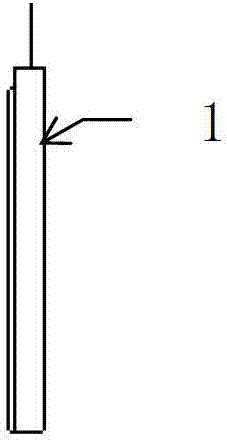

[0035] Such as figure 1 , 2 As shown, it is a structural diagram and a side view of the liquid lithium ion polymer battery before formation. The present invention performs formation and continuous production of the liquid lithium ion polymer battery shown in the figure.

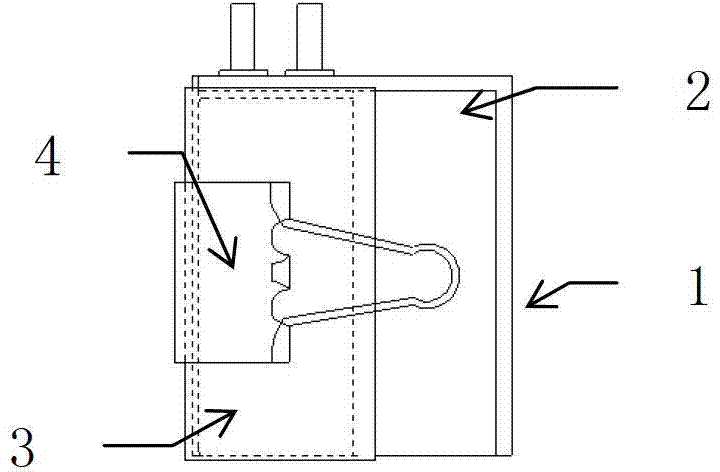

[0036] Such as image 3 , 4 Shown, the chemical composition capacity method of lithium-ion secondary battery of the present invention, comprises the following steps:

[0037] Place splints 3 on the left and right wide surfaces 2 of the uncharged liquid lithium ion polymer battery 1, which is a liquid lithium ion polymer battery that has completed hot and cold pressing and is not charged. object battery, the area of splint 3 is at least 1 / 2 of the area of wide surface 2,

[0038] Clamp two splints 3 with a clamp 4 that can apply external force,

[0039] Put the uncharged liquid lith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com