A silicon-carbon composite pole piece, its preparation method and application

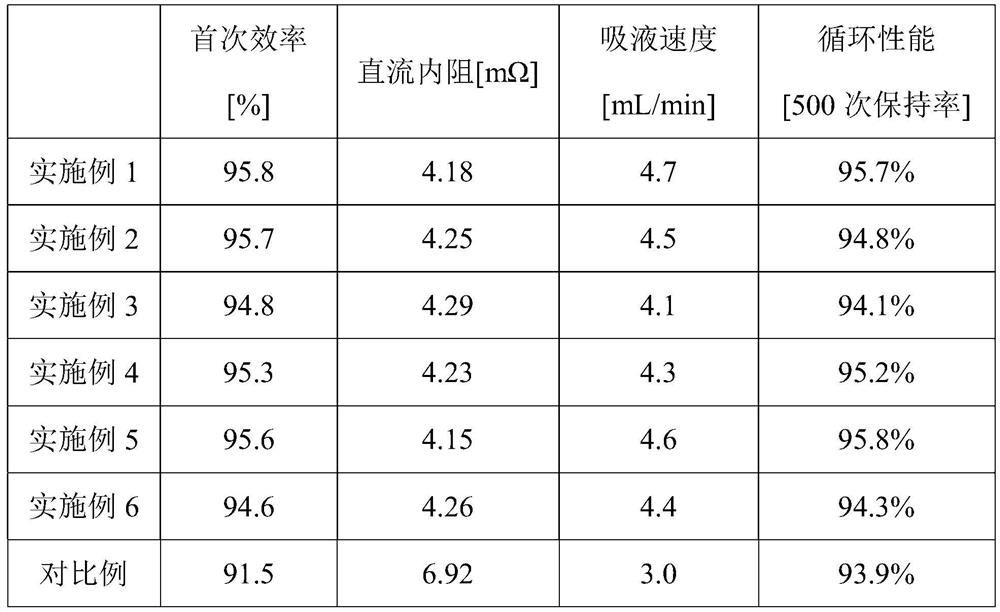

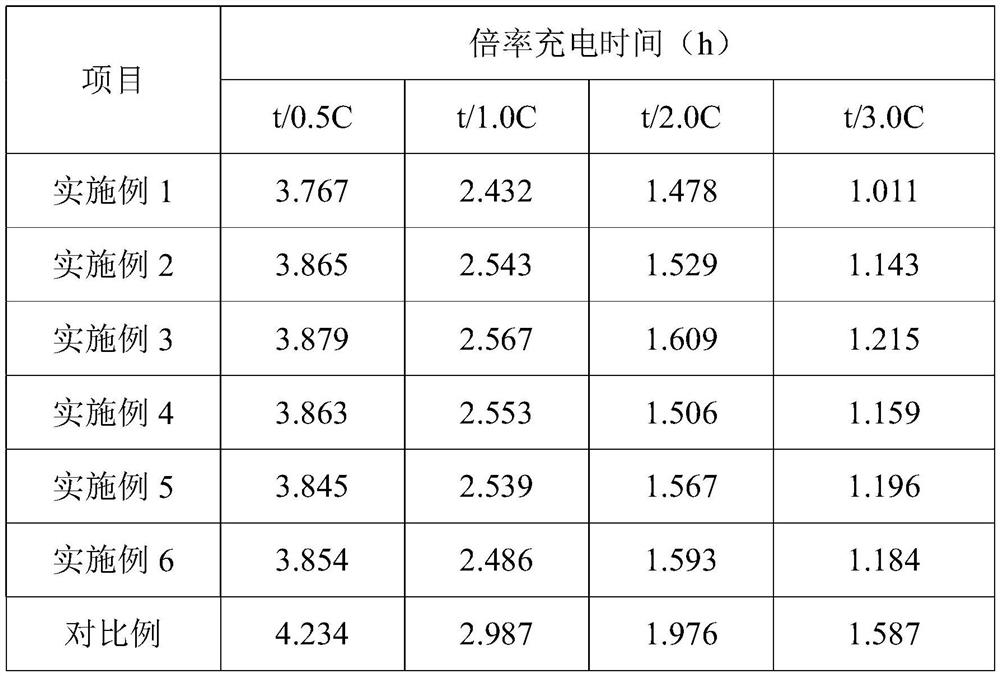

A silicon-carbon composite and pole piece technology, applied in electrode manufacturing, battery electrodes, structural parts, etc., can solve the problems of silicon-carbon negative electrode being less safe than graphite negative electrode, reducing the first coulomb efficiency, affecting battery safety, etc. The effect of increasing the transmission rate and improving the first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

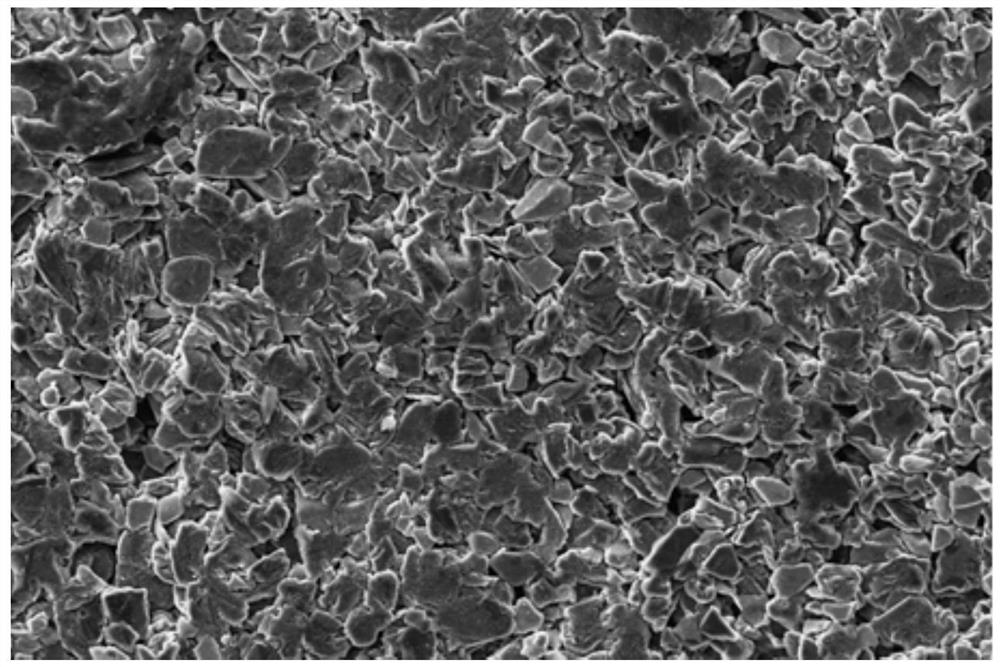

Image

Examples

Embodiment 1

[0060] This embodiment provides a preparation method of a silicon-carbon composite pole piece, and the preparation method includes:

[0061] (1) In the three-electrode system, a foam current collector (30 μm in thickness, 50% porosity) was used as the working electrode, a lithium sheet was used as the counter electrode, and a 0.1 mol / L lithium difluorooxalate solution was used as the electrolyte. Cyclic voltammetry (scanning from -2V to 2V) deposited lithium salts inside and on the surface of the foam current collector for 10 weeks, and after washing and drying, a prelithiated foam current collector was obtained;

[0062] (2) Mix the silicon carbon anode material, CMC, SBR, SP and water uniformly in a mass ratio of 93:1.5:3.5:2:150 to obtain a silicon-oxygen slurry; coat the surface of the pre-lithiated foam current collector 30μm thick silicon-oxygen slurry is dried and rolled to form a silicon-carbon material layer;

Embodiment 2

[0067] This embodiment provides a preparation method of a silicon-carbon composite pole piece, and the preparation method includes:

[0068] (1) In the three-electrode system, a foam current collector (30 μm in thickness, 50% porosity) was used as the working electrode, a lithium sheet was used as the counter electrode, and a 0.1 mol / L lithium difluorooxalate solution was used as the electrolyte. Cyclic voltammetry (scanning from -2V to 2V) deposited lithium salts inside and on the surface of the foam current collector for 10 weeks, and after washing and drying, a prelithiated foam current collector was obtained;

[0069] (2) Mix the silicon carbon anode material, CMC, SBR, SP and water uniformly in a mass ratio of 93:1.5:3.5:2:150 to obtain a silicon-oxygen slurry; coat the surface of the pre-lithiated foam current collector 20μm thick silicon-oxygen slurry is dried and rolled to form a silicon-carbon material layer;

[0070] (3) Mix the polyalkylene oxide, SP and N-methylpy...

Embodiment 3

[0073] This embodiment provides a preparation method of a silicon-carbon composite pole piece, and the preparation method includes:

[0074] (1) In the three-electrode system, a foam current collector (30 μm in thickness, 50% porosity) was used as the working electrode, a lithium sheet was used as the counter electrode, and a 0.1 mol / L lithium difluorooxalate solution was used as the electrolyte. Cyclic voltammetry (scanning from -2V to 2V) deposited lithium salts inside and on the surface of the foam current collector for 10 weeks, and after washing and drying, a prelithiated foam current collector was obtained;

[0075] (2) Mix the silicon carbon anode material, CMC, SBR, SP and water uniformly in a mass ratio of 93:1.5:3.5:2:150 to obtain a silicon-oxygen slurry; coat the surface of the pre-lithiated foam current collector 50μm thick silicon-oxygen slurry is dried and rolled to form a silicon-carbon material layer;

[0076] (3) Mix the polyalkyl acrylate, SP and N-methylpyrr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com