Trench junction barrier schottky structure with enhanced contact area integrated with a mosfet

A metal-oxide half-field and integrated structure technology, applied in the direction of transistors, semiconductor devices, diodes, etc., can solve the problem that the Schottky junction area cannot be effectively reduced, the forward voltage difference of the Schottky diode cannot be effectively reduced, and the components can be reduced. Efficiency etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

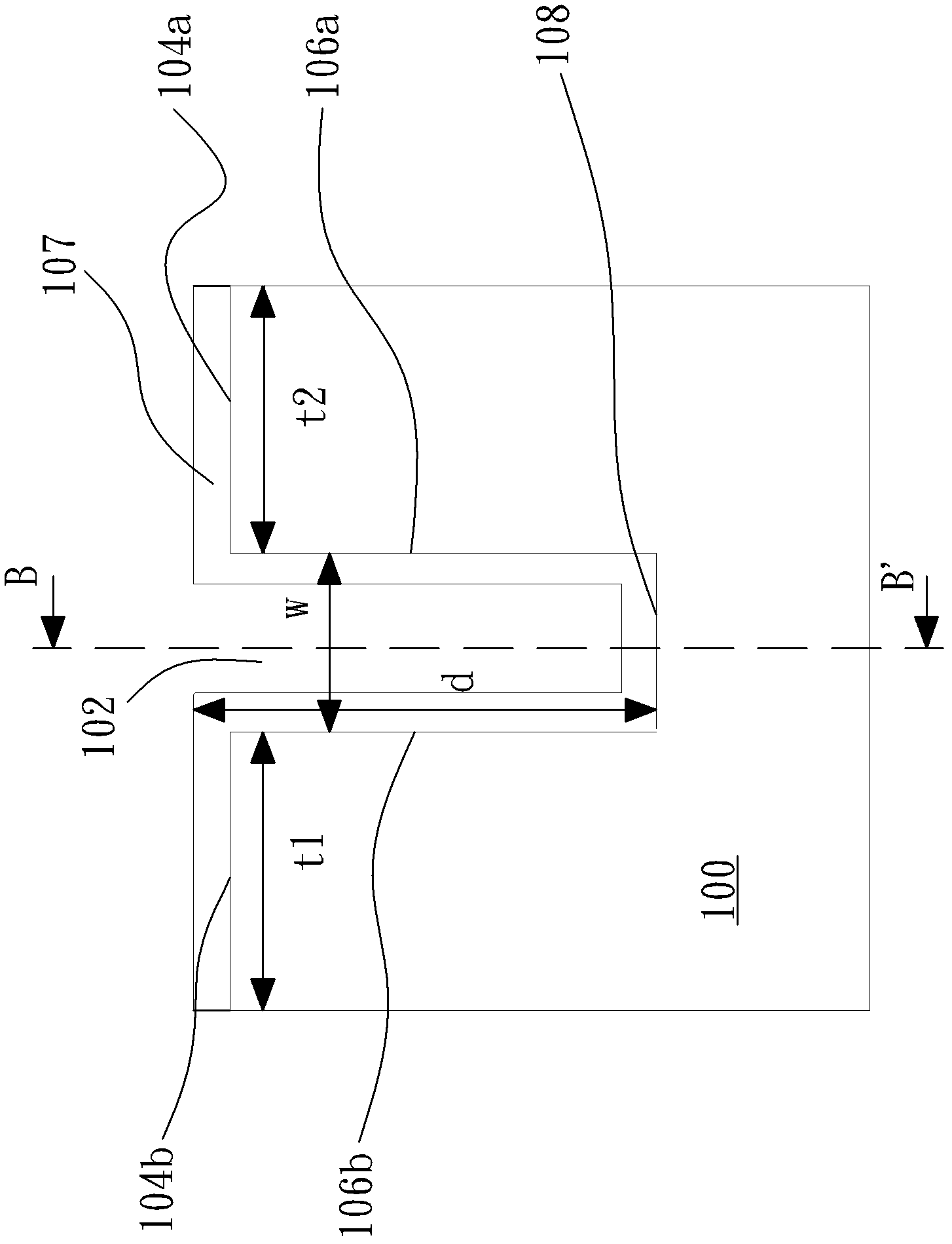

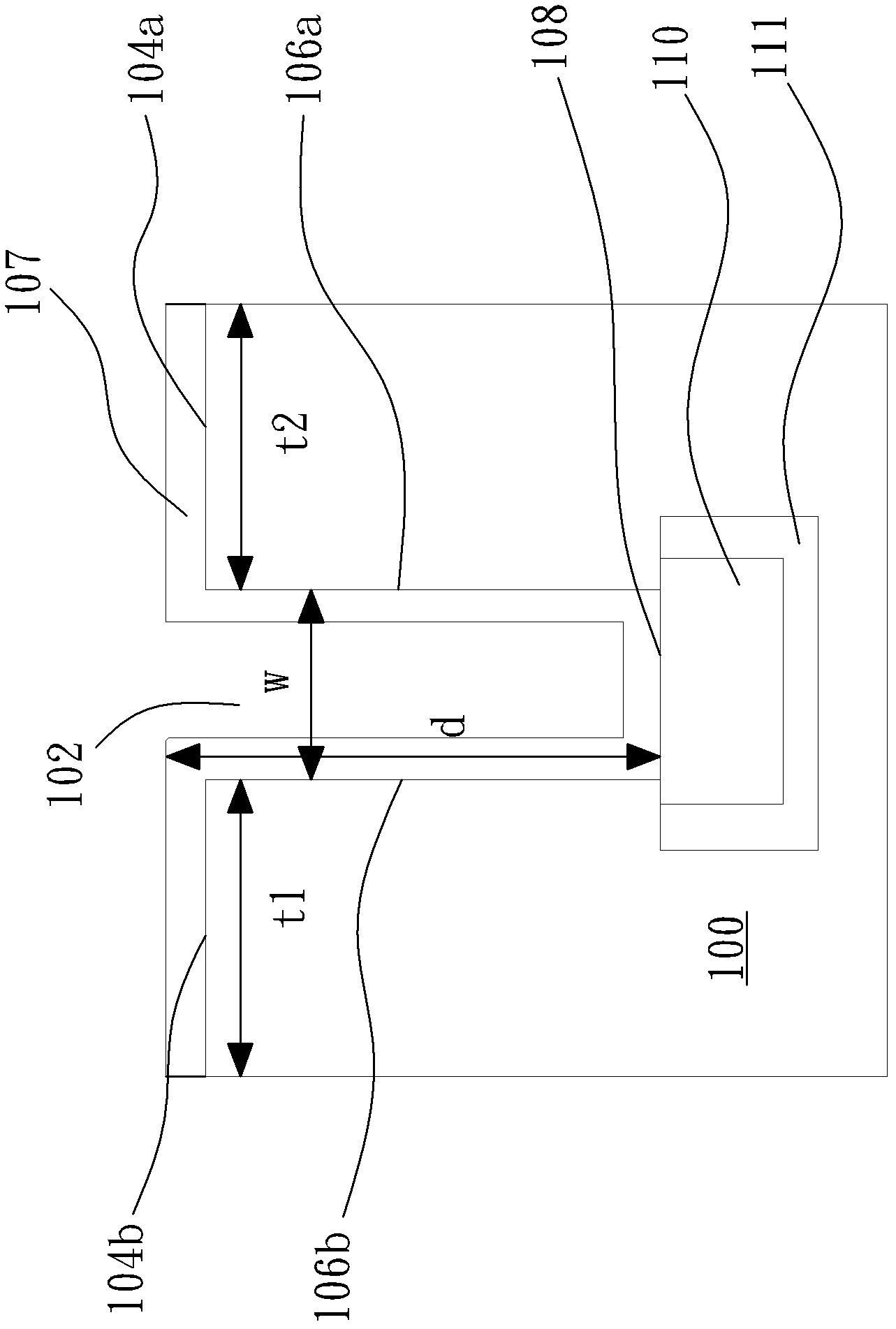

[0023] Figure 1A A sectional view illustrating a Schottky diode of the present invention. An n-type semiconductor substrate 100 is provided with a groove 102, the groove 102 includes a first side wall 106a, a second side wall 106b and a bottom platform 108, the position of the second side wall 106b is relative to the first side wall 106a. The bottom platform 108 is formed at one end of the trench 102 , and a trench opening corresponding to the bottom platform 108 is formed at the other end of the trench 102 . Next to the trench opening, there is an upper platform adjacent to the trench, for example, a first upper platform 104 a adjacent to the right side of the trench 102 and a second upper platform 104 b adjacent to the left side of the trench 102 . The inner surface of the trench 102 is composed of the first side wall 106 a , the second side wall 106 b and the surface of the bottom platform 108 .

[0024] A Schottky barrier metal 107 covers the inner surface of the trench...

no. 2 example

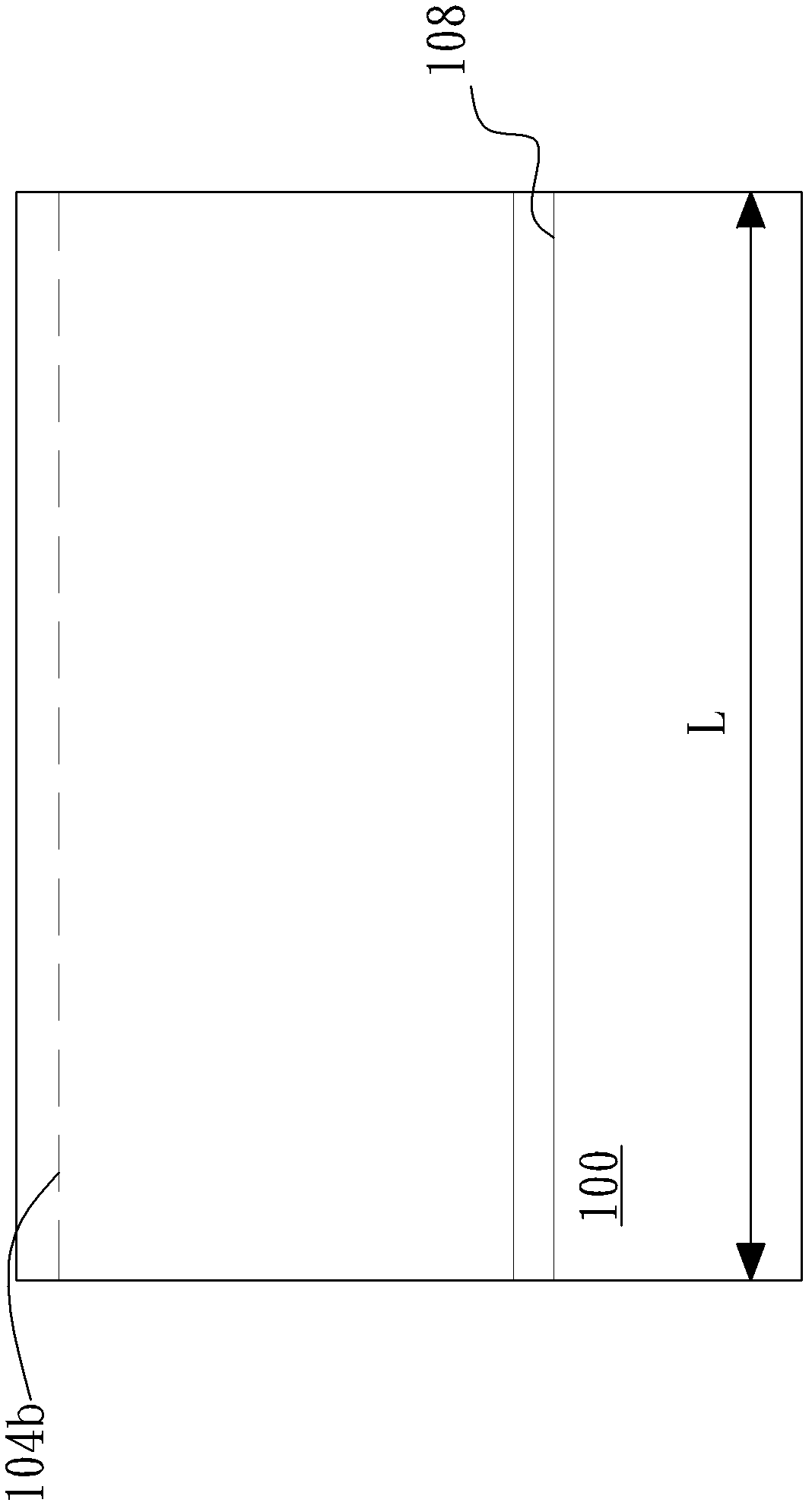

[0044] Please refer to figure 2 , which illustrates a cross-sectional view of a Schottky diode comprising a plurality of trenches and an upper mesa disposed on an n-type semiconductor substrate 200 .

[0045] The trench 202 includes a first side wall 212 a , a second side wall 212 b and a bottom platform 207 . Wherein the first side wall 212a is opposite to the second side wall 212b. An upper platform 214 is adjacent to the trench 202 . A Schottky barrier metal 208 covers the first side wall 212 a , the second side wall 212 b , the bottom platform 207 and the upper platform 214 . A contact metal 204 covers the barrier metal 208 to electrically connect the Schottky diode to external signals. A guard region 210 is located under the bottom platform 207 and doped with a p-type dopant to block the drain flowing under the bottom platform 207 from opposite sides of the first sidewall 212a and the second sidewall 212b. current.

[0046] Please continue to refer to figure 2 , t...

no. 3 example

[0051] Please refer to image 3 , illustrating an integrated structure of a Schottky diode and a MOSFET using a photomask process. The process includes the following steps:

[0052] Step S11: forming a metal oxide semiconductor field effect transistor (MOSFET) in a semiconductor substrate of a first conductivity type, and the metal oxide semiconductor field effect transistor (MOSFET) includes a source electrode;

[0053] Step S12: forming an insulating layer on the semiconductor substrate;

[0054] Step S13: disposing at least one trench and at least one upper platform on the semiconductor substrate of the first conductivity type, and the at least one upper platform is adjacent to the at least one trench;

[0055] Step S14: forming a region under the bottom of the trench, and the region is of a second conductivity type, the second conductivity type being opposite to the first conductivity type;

[0056] Step S15: removing the insulating layer from the at least one upper pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com