Carbon-doped titanium sapphire crystal and its growing method and application

A crystal growth, titanium sapphire technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of limited effect and unreachable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

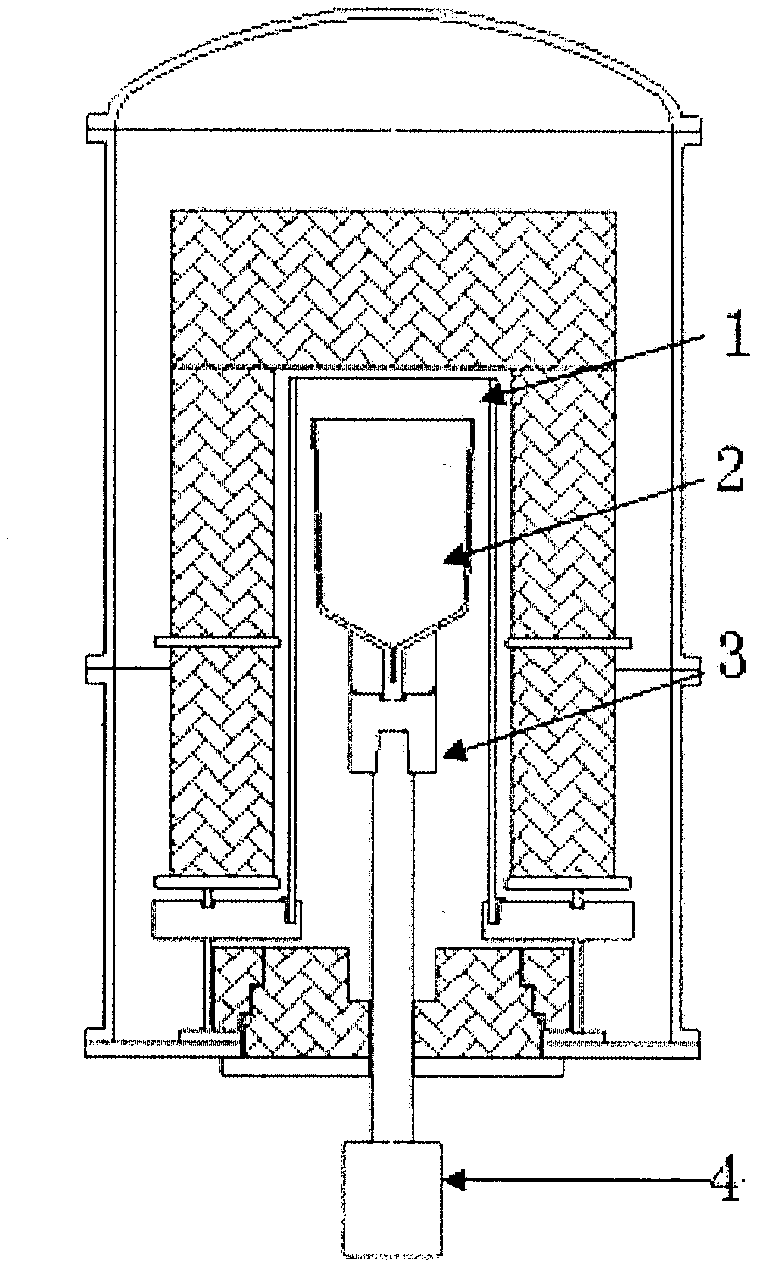

[0044] Embodiment 1: Growth of carbon-doped high-quality factor titanium sapphire crystals by crucible descent method

[0045] Put the oriented white gemstone seed crystal in the a-axis (110) direction in the seed crystal groove of the molybdenum crucible 2 in the descending furnace. Titanium sapphire raw materials are high-purity alumina (99.99%) powder and titanium dioxide (99.99%) powder, weigh 3000 grams of powder with a mass ratio of aluminum oxide and titanium dioxide of 100:1, add 1000ppm High-purity graphite (99.99%) powder, after uniform mixing, use 2t / cm 2 (tons per square centimeter) isostatically forged into blocks, pre-sintered at 1700°C in vacuum, and put into molybdenum crucible 2, and place them together on the crucible frame 3 of the descending furnace, and adjust the temperature of molybdenum crucible 2 and graphite heating element 1 distance to ensure that the centers coincide. After the system is sealed, vacuumize to 4×10 -4 Pa, the temperature rises to ...

Embodiment 2

[0047] Put the oriented white gemstone seed crystal in the a-axis (110) direction in the seed crystal groove of the molybdenum crucible 2 in the descending furnace. The raw material of titanium sapphire is high-purity alumina (99.99%) powder and titanium dioxide (99.99%) powder. Weigh 3000 grams of aluminum oxide 100:1 titanium dioxide mass ratio powder, add 3000ppm high-purity graphite (99.99%) powder, after uniform mixing, use 2t / cm 2 isostatic pressing into blocks, pre-fired at 1700°C in vacuum, put into molybdenum crucible 2, put them together on the crucible frame 3 of the descending furnace, adjust the distance between molybdenum crucible 2 and graphite heating element 1, and ensure that the centers overlap. The system is sealed and vacuumed to 3×10 -4 Pa, the temperature is raised to 1550°C. Fill high-purity argon to a positive pressure of 20KPa, continue to heat up to the melting temperature of 2060°C, and keep the temperature constant for 4.5 hours. After the raw ma...

Embodiment 3

[0049] Put the oriented white gemstone seed crystal in the a-axis (110) direction in the seed crystal groove of the molybdenum crucible 2 in the descending furnace. Titanium sapphire raw materials are high-purity alumina (99.99%) powder and titanium dioxide (99.99%) powder, weigh 3000 grams of powder with a mass ratio of aluminum oxide and titanium dioxide of 100:1, add 6000ppm of High-purity graphite (99.99%) powder, after uniform mixing, use 2t / cm 2 (tons per square centimeter) isostatically pressed into blocks, pre-fired at 1700°C in a vacuum, and put into the molybdenum crucible 2, and place them together on the crucible frame 3 of the descending furnace, and adjust the temperature of the molybdenum crucible 2 and the graphite heating element 1 distance, to ensure that the center coincides, the system is airtight, and the vacuum is pumped to 2×10 -4 Pa, the temperature is raised to 1500°C. Fill high-purity argon until the pressure is positive pressure 25KPa, continue to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com